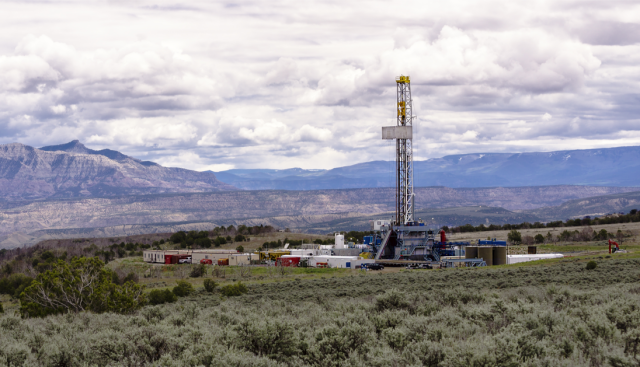

DENVER—With low operating costs, plenty of regional resources and backing from the Bank of Canada’s Canadian Pension Plan Investment board, Crestone Peak Resources is gearing up to begin operations in the Tier 1 part of the Denver-Julesburg (D-J) Basin in Wattenberg Field.

Tony Buchanon, President and CEO of Crestone Peak Resources, which began in 2016 and acquired Encana Corp.’s acreage in the basin, said at Hart Energy’s DUG Rockies Conference and Exhibition the company’s prospect is in the warmer, deeper part of the D-J Basin. It’s now in a more urban area of the state in southwestern Weld and eastern Boulder counties.

Wattenberg Field was first developed in the 1970s and covers more than 2,000 square miles between Denver and Greeley. It includes more than 23,000 wells producing from a number of Cretaceous formations. The bulk of the field is in Weld County, but it extends into Adams, Boulder, Broomfield, Denver and Larimer counties.

The reservoirs targeted in the field are Cretaceous in age and include the Dakota, Codell and J sandstones, Niobrara Shale/Greenhorn shale and limestone, and the Sussex and Shannon formations. Both the J sandstone and Dakota produce primarily gas, the Codell and Niobrara produce both oil and gas, and the Sussex and Shannon produce mainly oil.

“Although it’s in part of the ‘urban corridor’ along the Front Range, we’re working with local communities to develop a plan. As in any place where we work, first and foremost, we have to be an EHS-focused (environmental health and safety) based operator,” Buchanon said.

RELATED ARTICLE: DUG Rockies: Analysts Tout Strong Operations Despite Low Valuations

Buchanon also addressed the recently passed bill by the Colorado Senate, 19-181. The bill is aims to put public health, safety and the environment first when oil and gas development is considered and will give cities and counties more say over drilling activity within their boundaries.

“Because of where our acreage is, we’ve been kind of on the forefront of working with local governments. And it’s really important—we have agreements with the towns of Firestone, Erie and Dacono, and this has enabled us to come in and drill our wells and to work with them and answer their questions to be a really, really good partner with their communities,” he said.

“While the dust hasn’t settled on Bill 181, I think this will give us more certainty at the end of the day now that the playing field is leveled and the rules are out there. And if they change, they aren’t likely to change significantly,” he continued. “We’re still encouraged that we’ll be able to work with communities and still be able to develop oil and gas in Colorado.”

Crestone Peak Resources announced in 2018 that it plans to drill up to 180 horizontal Niobrara/Codell tests in a 12-section area of the D-J Basin in eastern Boulder County, Colo. According to IHS Markit, the Denver-based company has submitted a plan for the drilling program to drill multiple extended-reach horizontal wells from a few pads. Crestone Peak’s drilling program is in an area of the greater Wattenberg Field that apparently has no horizontally-drilled wells. It contains vertical and directional wells producing from Niobrara, Codell, Sussex and J sandstone.

The company plans to run two rigs and spend about $250 million on their drilling program over the next year. At its rig sites, it will be using sound walls and an electric fleet of drilling rigs that are plugged into the local utility grid.

“With the electric rigs, you can actually walk on the drill floor and have a normal conversation like we have in this room,” he said.

Crestone also has a new 1,500-hp rig coming in that can do extensive pad drilling and drill up to 3-mi. laterals, and it can also ‘walk’ with about 28,000 ft of drill pipe on the rig.

“With this, we can drill larger pads, decrease our footprint and reach out further with horizontal drilling in a limited location in areas where there is residential development going on,” Buchanon said.

Buchanon added that one of the issues that was raised by meetings with local community members was odor. “We prefer to use oil-based muds because it gives us a better well bore,” he said. “We worked with Shell Oil and they have a product that was developed in Qatar called Shell Neoflow base fluid and it is almost odor-free.”

Buchanon also said that they are able to drill a two-section lateral well in about eight to nine days. One issue that can add a day or two to drilling is running through old coal beds or seams, and it can add two to three days because they have to set an extra string of casing.

To date, the company has drilled approximately 172 wells with two rigs since October 2016. Buchanon noted that when Crestone took over the acreage from Encana, [Encana] hadn’t drilled a well on the acreage in about three years.

Buchanon said that Crestone has been working with Schulmberger. They have been using the company’s Flex Seal well bond, which has been used to prevent any surface casing (Bradenhead) pressure issues.

Regarding completions, Crestone is also running its frac fleets from ‘frac pads’, where it can run two frac fleets or have a centralized pad.

“It helps us accelerate well completion especially where we are drilling 20 to 25 wells per pad” Buchanon said. “Another advantage is that the frac pads reduce the time spent on a location.”

Crestone uses Liberty Oilfield Services with the company’s ‘Quiet Fleets’ that uses sound reduction technology in fracturing equipment. According to Liberty, noise levels are reduced by a factor of three compared to a conventional fracturing fleet. The company’s innovation in noise reduction has lower sound levels at a distance of 500 ft from the center of a frac location than a conventional fleet would have at 1,000 ft.

According to Buchanon, Crestone will drill multiple wells form a single pad and at one pad in Weld County. It plans to drill 43 wells form a single pad (File Hwy 52), with 2-mi. long laterals.

The company’s acreage is not far from acreage held by Anadarko Petroleum in Weld County.

“They’ve done a great job here in the basin and we’re not really ashamed to admit that we’ve copied a lot of the successful techniques that they’ve used and added our own techniques including 165-foot spacings with six perf clusters, 36-37 barrels per foot of slickwater jobs and about 800-900 pounds of sand,”Buchanon said.

He explained that because their wells are in the warmer, deeper gassier, the company won’t have to use the same sand concentrations as much as another operator would in in a part of the basin where there is more oil.

He also noted that because of geological variable within the basin, there really isn’t a one-size-fits all approach.

Crestone Peak Resources is also active in the Codell sandstone.

“We can run 300-foot stages with six perf clusters with 24 perfs because it’s more permeable than Niobrara and we can run lower frac volumes and that helps keep costs low and frac costs are about two-thirds of our costs,” Buchanon said.

He also said that possible future Codell testing could include cluster spacing and other methods to increase efficiency.

Recommended Reading

BKV CEO Chris Kalnin says ‘Forgotten’ Barnett Ripe for Refracs

2024-04-02 - The Barnett Shale is “ripe for fracs” and offers opportunities to boost natural gas production to historic levels, BKV Corp. CEO and Founder Chris Kalnin said at the DUG GAS+ Conference and Expo.