For the past two years in Oklahoma there has been pretty good rainfall, which has replenished surface water that is used in fracturing operations in the Scoop, Stack and Merge plays in the west-central part of the state.

Companies like Roan Resources Inc. have been using 100% surface water and trucking the flowback and produced water to disposal wells. But they are aware there is a limit to how long a company can use freshwater for its operations.

“If you look at the state historically, there have been periods of drought,” said Byron Cottingham, senior engineer for Roan. “Our plans for the future as an organization are to begin recycling produced water and also be a good environmental steward by trying to prevent wastewater disposal and offset freshwater use.”

One needs look no further than the 1930s Dust Bowl in Oklahoma to know how devastating droughts can be. At that time, the federal government created soil- and water-conservation districts. Water conservation included having farmers and ranchers build water storage ponds—which are now a source of surface-water supply.

“We’ve been able to keep up with finding freshwater and surface-water sources. Luckily we’ve had a lot of rainfall. But I think recycling produced water would potentially reduce the risks of freshwater sourcing,” Cottingham said.

Michael Frow, petroleum engineer consultant with Argentum Energy Resources LLC, explained that the demand for water will grow exponentially in Oklahoma as operators in the Scoop, Stack and Merge move from newfield development to full-field development.

One operator calculated that it was going to take 5 billion barrels (Bbbl) of freshwater to develop newfield acreage. If that is for only 10% to 20% of the entire play—or maybe a little larger number—the range is between 25 Bbbl and 50 Bbbl of water for full-field development, Frow said.

“It won’t happen all at once, but that is still going to be a major drain on resources. At some point, you are going to start competing with drinking water for the populace and extreme drought conditions, which is an issue in Oklahoma,” he said.

“It seems like Scoop and Stack are starting to hit their strides as far as fewer leasehold obligations and more full-field development. I think you’re going to see a lot of increased activity and greater demand as far as freshwater supply is concerned as well as saltwater disposal.

“I don’t think we have all the solutions in place right now, although there are companies working on that. I think there are still opportunities to step in and look at the long-term picture and get something that is beneficial to all the operators involved.”

Those are some of the drivers behind water management in Oklahoma. Seismic activities caused by injection wells remain a major impetus for the state to move away from surface water to recycling flowback and produced water.

Laura Capper, principal, EnergyMakers Advisory Group oil and gas consultancy, said, “I think we’re figuring out how to manage seismicity better. I remember, two years ago, I was contacted and requested to find examples of companies doing recycling in the area. I could not find anyone at that time. Everybody was kicking tires, but nobody was actually recycling and reusing water.”

Contrast that today with a general estimate at a conference in mid-December that there were 30 different recycle programs going on in the Scoop/Stack area.

Reduced seismicity

The Oklahoma Geological Survey (OGS), Oklahoma Corporation Commission (OCC) and University of Oklahoma continue to look at earthquake issues. Capper said, “The OGS guys really have done a lot of analysis on the area and continue to believe that much of the seismicity was driven by injection. The OCC did a pretty good job of curtailing the activity levels when they had people plug back from the Arbuckle formation.

“Within 12 to 18 months, they saw pretty strong response. Earthquake levels dropped pretty dramatically. I think they’re now running one-fourth to one-third the level we saw during the peak year in 2015. That has been through water management largely by constraining injection rates in certain areas and injection depths.”

The OCC has guidelines on induced seismicity both for saltwater-disposal wells and hydraulic-fracturing operations. “We are aware of those guidelines and regulations and hold a high standard of being 100% compliant.”

Currently, no one is requesting permits for new injection wells into the Arbuckle. Frow said, “The OCC won’t grant permits in the Arbuckle for saltwater disposal. Most people have been switching to the Wilcox sand as a disposal zone since that is farther away from basement rock.

“Hopefully this remains a long-term viable solution, and we’re not forced into a situation where, from a regulatory standpoint, we abandon disposal wells as our primary solution and rely on recycling produced water. Everyone wants a better long-term solution that benefits all stakeholders.”

One aspect of the Scoop/Stack is that there are fewer water hassles than in other parts of the state since the formations are drier. “There is not a big concentration of disposal wells in that area like some other areas in the state that have higher water/oil ratios,” Capper said.

“The Mississippian [play] in northern Oklahoma has an extremely high water cut. In the Scoop/Stack it is quite a bit drier, so there is less water to mess with. Interestingly, although injection volumes are lower than other areas, even so there is low-grade seismic activity in the Scoop/Stack.

“Unique to this area in Oklahoma, regulators now believe some of this low-grade activity is likely associated with hydraulic fracturing and not injection. They’ve known that since the tail end of 2016 when they announced there was some correlation there.”

In addition to complying with regulatory-imposed “traffic light” systems, operators are also self-policing in the area, both for fracturing-related and possible injection-related activity. “They are putting in seismic-detection systems, and there is a pretty strict set of OCC criteria for reporting different events,” Capper said.

If a company detects it might be causing a low-grade event, they have to back off the pressure pumping, let it calm down, keep an eye on it and report it to the regulators, she explained.

The general vibe she picked up at various meetings is that a lot of operators are a little more comfortable that things are under control in the area. “We’re getting our hands around the seismic issues, where a year or two ago there was more urgency about it,” Capper said.

Recycling interest

Produced water recycling in the Scoop/Stack/Merge is just getting started. That is both the good news and the bad news. The good news is that the operators will be able to use the experience of companies in other plays that have large recycling volumes. The bad news is that they have to invest in quickly catching up.

As far as purchasing freshwater in the Scoop/Stack/Merge, the costs range from 20 to 50 cents per barrel, Frow said. The cost of disposing of saltwater has a wide range. “If you have operator infrastructure, it could run below $1 per barrel. If you’re in a high-demand area and have to truck all your saltwater to disposal wells, it could run $5 to $6 per barrel. Ideally you want to be under $1 per barrel. Anything over $2 per barrel I would consider excessive, and you would need to deploy capital to definitely get that under $2.”

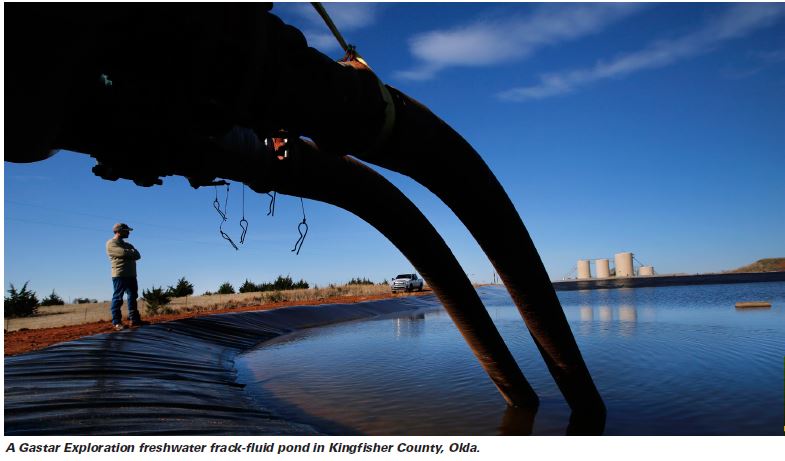

(Photo: Tom Fox)

Both Cottingham and Frow agree that the biggest benefit of recycling water is getting trucks off the road.

“On the hydraulic-fracturing side, recycling should drive down the costs. Really the gap in costs comes from the removal of trucks and the adding of pipeline on the flowback and water-handling side,” Cottingham explained. “As far as the costs of recycling vs. freshwater sourcing, those costs are relatively neutral.”

Roan Resources has been looking at recycling for more than a year. “We’re looking at several different technologies side. There are several technologies and each one has different pros and cons as far as the technical approach.”

The company is most comfortable with microbe technology. “These microbes and aeration in combination with pits will help get water quality to where we can use it on the fracturing side. In the area we’re in, mainly in the Merge, flowback water is in good quality as far as total dissolved solids and ions. So the treatment is relatively minimal to get the water to good quality,” he said.

In addition to Roan, Frow pointed to Continental Resources Inc., Newfield Exploration Co. and Encana Corp. as already being active in recycling. “I think Continental, in some cases, is using up to 50% recycled brine water. As long as there are no compatibility issues with completion fluids, which is a very viable option.”

From a freshwater point of view, companies may have to recycle flowback if they can find a way to make the process economical and compatible with fracturing fluids, he said.

Cottingham said that, in Roan’s area of operation, there is a good amount of water sourcing available. The company is pushing ahead on a project for water recycling. “It wouldn’t be the first one in the state. There are several other operator that do it, but they’re also larger operators.

“We’re probably a good mid-size operator trying to be innovative to help not only our operations but also for community relations as well. Nobody in the Merge has looked at water recycling yet to my knowledge other than us. It is something that we’re trying to lead in this new play area.”

Capper pointed out that people are pivoting and trying to go after brackish water once they get their treatment processes calibrated for it. “You’ve got a lot more of that accessible and that is not as precious as freshwater. In general, there is less concern these days about supply water being an issue mainly because they backed off freshwater and are using more brackish water.

“What we’re seeing in general is that folks are getting a lot more creative about just trying to reduce their disposal volumes. That is increasing the market for recycling most definitely. There was very limited recycling a couple of years ago and now there are substantial volumes.

“I think another thing that has happened is that we’ve gone back to slickwater fracturing. That makes it easier to recycle as well. It is not as complicated to get your water where it needs to be with a slickwater frack.”

“On the hydraulicfracturing side, recycling should drive down the costs,” said Byron Cottingham, senior engineer, Roan Resources Inc.

“On the hydraulicfracturing side, recycling should drive down the costs,” said Byron Cottingham, senior engineer, Roan Resources Inc.

There is considerable interest in evaporative systems, which might be used in the area, she added. “There’s a lot of tire-kicking going on. The beautiful part of evaporative systems is that they’re keeping fluids in the hydro-cycle, and that is appealing to all concerned.

“The downside is you’ve got all that salt left over that you’ve got to manage. There is a growing trend of technologies that can help recover the salts in such a way that the quality is good enough you can sell them.”

Pipe vs. truck

Roan Resources currently hauls wastewater to third-party saltwater-disposal wells. Cottingham said, “The future plans would be to put that water in pipelines and remove as many trucks from the road as we can and allow us the opportunity of recycling the water. The main cost-driver to decrease our water costs is the differential between truck-hauling and pipeline.”

The company has been going through the engineering and planning process during the last year to begin laying out how it would run a pipeline, which brings with it benefits. “One benefit is we’re going to get trucks off the road, which is going to be great for community relations and environmental stewardship,” he said.

“It will also drive down the costs associated with water flowback if we can use piped water instead of trucks.”

Capper said, “Clearly water logistics in Oklahoma are a little trickier now because you do have constrained disposal capacity in some areas. The implication is you’re going to have to take your water farther to find a receptive formation that you are comfortable with. But that is going to add to your transportation costs.

“Then you get in a dilemma. Are you going to put more trucks on the road or are you going to commit to a longer-term program with a midstream company? There is a lot of jockeying going on, trying to optimize economics within a comfortable level of commitment to the midstream water-pipeline companies.”

Water-related midstream activity in the plays has picked up. For example, in September, Macquarie Infrastructure Partners (MIP) invested in Lagoon Water Solutions Holdings LLC. Lagoon works with producers to reduce operating costs through investing in, constructing and operating water-midstream infrastructure.

MIP committed up to $500 million to support additional growth in the Stack, Scoop and plays in other basins. Initial capital will focus on the expansion of Lagoon’s current assets. Following this expansion to serve these producers as well as other customers, Lagoon was expected to have more than 350,000 barrels of water per day of disposal capacity across 17 facilities and more than 150 miles of water-gathering pipeline by the end of 2018.

Hose brouhaha

EnergyMakers’ Capper reported in a September blogpost that there was a major brouhaha in Kingfisher County in the summer over the use of flexible, lay-flat hoses in produced-water transportation. “Oil and gas companies operating in the county state that they have used heavy-duty pipes and hoses for years to transport water to and from well sites in support of drilling and hydraulic-fracturing operations.

“But, this seems to be news to Kingfisher County commissioners, who say that they discovered just this spring that E&P companies have been using temporary pipes and hoses to transport water of widely varying quality levels.”

The county commissioners enacted new rules in May, allowing permits only for freshwater. Oil producers were blindsided by the rules, which would drive up costs. “Moving a barrel of water in a pipe costs pennies vs. dollars with trucks. Such a sizable jump in transport costs significantly alters the production economics for area operators, who could logically respond by drilling fewer wells in the area,” she reported.

A lawsuit was filed in late August by the Oklahoma Oil & Gas Association against the county commissioners, saying the ban violated state law. The suit went to the Oklahoma Supreme Court.

The Kingfisher Times & Free Press reported in November that the Oklahoma Supreme Court ruled against the county commissioners. In a 6-3 decision, it stated that the OCC had exclusive jurisdiction to regulate oil and gas activity, including transporting and disposing of produced water. The commissioners have decided to request a rehearing.

Recommended Reading

Marketed: Anschutz Exploration Corp. WI Opportunity in Converse County, Wyoming

2024-01-26 - Anschutz Exploration Corp. retained EnergyNet for the sale of its WI participation option in Converse County, Wyoming.

Excelerate Energy, Qatar Sign 15-year LNG Agreement

2024-01-29 - Excelerate agreed to purchase up to 1 million tonnes per anumm of LNG in Bangladesh from QatarEnergy.

UK’s Union Jack Oil to Expand into the Permian

2024-01-29 - In addition to its three mineral royalty acquisitions in the Permian, Union Jack Oil is also looking to expand into Oklahoma via joint ventures with Reach Oil & Gas Inc.

Permian Resources Continues Buying Spree in New Mexico

2024-01-30 - Permian Resources acquired two properties in New Mexico for approximately $175 million.

Eni, Vår Energi Wrap Up Acquisition of Neptune Energy Assets

2024-01-31 - Neptune retains its German operations, Vår takes over the Norwegian portfolio and Eni scoops up the rest of the assets under the $4.9 billion deal.