Vaquero - The Spanish word for cowboys - brought the cattle culture to Texas hundreds of years ago. Long drives to move herds north from Mexico City into what was then the frontier state of Coahuila y Tejas was harsh, isolated and dangerous work. The challenging conditions required those first cowboys to embody trust, respect, safety, courage, integrity, a strong work ethic and a can-do spirit.

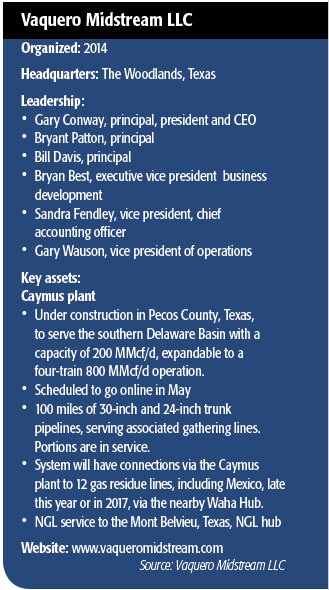

Those remain worthy attributes. Vaquero Midstream prizes those same values today as it pioneers a major gathering and processing system to serve producers in the booming southern Delaware Basin. The firm’s CEO, Gary Conway, took time to visit with Midstream Business to explain how those ideals, embodied so long ago, can bring success to the high-tech midstream of today in West Texas.

MIDSTREAM Please talk a little about your career prior to Vaquero. You’ve held several executive roles.

CONWAY After graduating from Texas A&M with a chemical engineering degree, I went to petrochemicals, ethylene plants—those were the only jobs that were out there at the time. So I came to Houston, started with ethylene plants and was all over the world. Growing up in East Texas, I was around oil and gas and decided to get back to my roots.

I managed to push my way back to more of the gas-processing side of things. I ended up getting an opportunity with Crosstex Energy Services [LP] right at the time in which it wanted to make a go of amine treating and related businesses in producing areas, particularly South Texas and West Texas. And that’s how my enthusiasm for the midstream business started.

I would credit Crosstex under Barry Davis’ leadership in that regard, helping to spark the entrepreneurial side of things for me. That was my first exposure to scheduled execution where customer service and engineering meet. Those projects gave me some inkling of just how to really start the fi re of entrepreneurship. I then moved to manager of engineering and projects to Crosstex and, as we were growing, over 100 amine plant installs later, I joined Energy Transfer just as the Barnett was in its initial development. It was a new deal; we had to figure out some ways to do things. It was a unique opportunity to lead multiple projects developing an asset from a dairy field to a half-Bcf [billion cubic feet] of cryogenic processing complex. In addition, I was responsible for operating the complex at the same time. If Crosstex cranked up the entrepreneurial machine, ETC and CEO Kelcy Warren opened the box wide open.

In 2008, I was approached by a couple of management team guys I had worked with during my time at Crosstex. They said, “Hey, look, we have an opportunity here to build a midstream company directly for a producer, Petrohawk.” I wanted to under-stand more about our business from a producer prospective while utilizing what I had learned about building infrastructure. So, northern Louisiana here I come. I was able to put together a team and complete Petrohawk/Hawk Field Services’ Fayetteville system and built out the Haynesville system while starting to work on its Eagle Ford system before Petrohawk sold Hawk Field Services. Being in the midstream arm of your own producing company, I gained a new view, the producer’s point of view, and the importance of coordinating efforts and the profitability advantages of teamwork between the two companies.

In 2010, I had a high-level meeting with two of the original management team members previously at Crosstex at the Dairy Queen in Canton, Texas, as they had started private equity-backed Teak Midstream [LLC]. My role at Teak was as their vice president of engineering and operations. Taking my 20 previous years of experience, from a leadership perspective, from an engineering execution and design perspective, it rolled into one focus of building a high-quality team, world-class asset in South Texas’ Eagle Ford, while driving value back to the customer.

The biggest difference working with Teak was the exposure within a private equity business model, what private equity looks for in management teams, asset creation, returns, etc. How do you execute within this model? I was involved from the board level and absorbing the financial perspective.

MIDSTREAM You are in the executive suite now. Has that chemical engineering degree been a plus?

CONWAY Absolutely. There is an old joke that chemical engineers aren’t necessarily smarter, they just know how to look it up faster! The A&M chemical engineering degree program provides that you take mechanical, electrical and civil engineering classes, as well as your chemical engineering classes, so you have a wide engineering exposure. It really does set you up well for a broad spectrum—like what we’re doing at Vaquero.

But the people aspect, I don’t think any degree program sets you up for that. You either have it or you don’t. You can develop techniques but it’s hard to get somebody to follow and to accept you as a leader if you just don’t have some people skills also.

MIDSTREAM How did your past experience impact what you’re doing now at Vaquero?

CONWAY I don’t know that anyone can look back on their career and not have a series of lessons learned, whether those were failures or successes, or if there are things that you did or didn’t do. It created who you are from a work-related perspective. And really, what we’re doing here at Vaquero is taking all of those pieces—the entrepreneurial frame-work, the knowledge of how to build large infrastructure and adding the producer mindset of specific needs.

Vaquero created a team that not only fertilizes that experience and makes it grow, but also takes a right perspective on how to do it, which is our Vaquero culture. Just do what you say you’re going to do. It’s all about integrity, which I think we have kind of lost a little bit in our midstream industry today. We (midstream) may have lost some of the customer service end of things, and we want to do our part to put more confidence in midstream—and particularly our Vaquero team.

MIDSTREAM Your first system is going in now to serve the southern Delaware Basin. The Delaware is seeing a lot of new midstream capacity additions. What’s Vaquero’s advantage?

CONWAY I think our advantage is not only our team strength, experienced skill set, philosophy and simple approach, but that we are very willing to demonstrate our performance—not just tell producers about it—and an aggressive private equity partner in Yorktown. Based on what we have heard from producers to date, they are looking for a midstream company they can count on. I know that sounds really simple, but it can be just that simple.

MIDSTREAM You plan to be in service in the second quarter, how is the project progressing?

CONWAY We’re very excited, obviously. We’re on track to be running in May, which has been our goal and our focus from day one. We’re currently assisting producers, utilizing portions of our system now for interim solutions until we get the processing plant up and running.

MIDSTREAM The West Texas Waha gas hub seems to be growing in importance, thanks in great part to Mexico’s emergence as a major market for U.S. gas. What can midstream operators do to make the hub work better?

CONWAY You know, the interesting thing is we actually got a couple of industry giggles when we said Vaquero wanted to locate our plant near Waha. We felt like this was a very strategic and advantageous place for the plant to be sited.

They said, “Why don’t you put it on the guys’—your producers’—acreage?” But what makes sense is we can always build gathering lines, but it’s much more difficult to demonstrate flow assurance with only one market outlet for residue gas. We felt like Waha was the right place to be—and we’re not the only ones. Kelcy Warren said he believes that Waha is going to be the market of the future, and he’s since been joined by others in our midstream business.

But as far as the hub itself, it’s like any other hub. It’s a very sophisticated logistics network. Don’t let going out there and seeing cactus, scrub brush and dirt fool you. It requires, for any growth, greater coordination and communications to take all these processed molecules into the long-haul pipes to the various marketplaces, especially Mexico.

We actually think that competition, on the long-haul side of things, will help to drive hub operators to get better, creating some more commercial and capital efficiencies, maximizing the product-value chain for the producer. We are the middleman in all that, we just connect the two ends—the source to the market so that the producer can benefit from the market. The price advantage to the producer based on this location can range anywhere from 10 to 15 cents per thou-sand cubic feet. That is a big number.

MIDSTREAM What makes the Delaware different from the rest of the Permian?

CONWAY It’s an interesting area. I was attracted to it several years ago because it is wide-open spaces and no fences—and there is probably a reason for that. But at the end of the day, this area really lacks appropriately designed and capacity-related infrastructure, that’s the big deal. And then underlying that is the fact that it has multipay drill zones and opportunities for producers that are greater than most shale plays.

The Midland Basin is pretty crowded but the Delaware is fairly wide open. And again, it gets back to there are opportunities for incumbents and other midstream operators to offer solutions. They [solutions] just weren’t there, or were singular, so that’s where Vaquero stepped in to offer multiple opportunities.

MIDSTREAM Yorktown Energy Partners VI LP, a familiar player in the mid-stream, has been your equity partner. Have they played a role beyond dollars-and-cents in Vaquero’s development?

CONWAY Yorktown has been around for a long time with a long record of success, from upstream to midstream. Yorktown’s early midstream investments actually included Crosstex Energy. It was during this time Bill Davis, one of our principals and partners, was exposed to Yorktown and the confidence between the two was pretty strong and it became a natural fit.

They know a lot about the growth of midstream and how to get a mid-stream growth story into an MLP vehicle as well as about midstream when it comes to a private equity-backed operation and selling to an MLP.

If that wasn’t enough, Yorktown understands upstream producer business—what it looks like in buying acreage, geology, about how to drill, what it costs to drill and what are the right costs—brought great knowledge to our team. In addition, they see a producer economic side to things that has provided a greater basis for us to understand producer challenges.

I would say, with that vast knowledge base, they have been most helpful to us in an advisory role. Yorktown is much more than a board member. This is probably the most rewarding relation-ship I have ever had to work with in an equity group. Their capabilities are out-standing, and their gut feel and intuitive sense—about business in general, his-tory and overall industry intelligence—is phenomenal. It has been extremely easy to work with them; it’s all about trust.

MIDSTREAM In your recent presentation at Hart Energy’s Midstream Texas conference, you emphasized “the Vaquero culture.” How does that culture make your company different?

CONWAY I was raised in a certain way of character and tradition, that a person’s word meant something, that a work ethic was important. How you respect people—your stewardship of others’ time, the relationship that you create, your reputation and commitment—these are all important. And loyalty: I mean, back in the day, vaqueros or cowboys rode for something.

We seem to have gotten away from that on a global scale, and we at Vaquero make a conscious effort to put service back, at least in an area where we can have an impact. That’s important to us.

The way I look at things is a way of life for me. I enjoy the western lifestyle. We have horses. I rope, ride and show reined cow horses and the atmosphere in these events illustrates a way of com-munity that is simple but meaningful.

The vaquero’s style of training is to build a willing partnership with your horse and that takes time, patience, skill and commitment. That was relationship-based training and it was more about skill and understanding, discipline and how you approach things. In dealing with my own horses, they have an honest way of teaching you at the same time you are training them. The end result is a willing partnership by both man and horse.

Take that approach and you can develop willing partnerships with your producers. Why wouldn’t you want to do that? And you do the same thing with contractors and people that work with you to develop the asset. We have built strong relationships with Saulsbury Industries installing our plant and Strike Construction on the pipeline side of things. It’s definitely more of a team atmosphere, a team perspective, and I think that makes us different. We carry those same key values and philosophy no matter what we’re doing, commercially, on the execution side of things, from a team-building perspective—and how we treat one another as extended family. Our team is top notch.

MIDSTREAM How does that culture impact your management style?

CONWAY I am a do-what-you-say-you’re-going-to-do person. I think it falls under your level of integrity, personally, and that’s been ingrained in me since I was a young man, my parents were very much that way. The Vaquero team is of the same ilk. My time at A&M, a land of tradition, continued to instill character and commitment. It’s ingrained in the fact that you treat people fairly, as you want to be treated. And I think that should be displayed in how you live your life and how you do your business.

MIDSTREAM Everyone has an opinion on when commodity prices will turn around. What’s your expectation?

CONWAY I don’t think our opinion is going to change prices. We thought some different things were going to happen with propane as we started exports. We thought there were a lot of things that were going to be different. I think it has already been said that, as soon as we think we have a consensus, then the consensus is actually going to be wrong. Who knows?

What we do know is we have capitalism here in this market, where we’re trying to get energy independent, we’re looking for cheaper energy sources. Our open market creates competition, which helps drive things to a place where everybody should be able to compete.

But one of the things at Vaquero, with Yorktown’s help and backing, is we have chosen to be more forward in our thinking, in our strategy. We have chosen, that regardless of the market is doing today, we believe the market’s coming back. We need to be ready for that. We need to be ready when the producer’s ready. We are not stopping what we’re doing because it’s the right thing for the entire basin.

That’s what we’re thinking about here: we plan for a solution, we lay it out, we do our homework, we look at the design, we look at the needs. We invested a good deal of capital into studying the basin and looking at the same production capabilities the producers are. We are going to be ready, both now and when the market really comes back strong and accept producers at their time of ramp-up—to be the basin solution.

MIDSTREAM Where do you see the greatest opportunity for Vaquero outside of the Delaware Basin? Are you looking outside the Delaware yet?

CONWAY As a CEO, you’re always looking for how to help the team improve and display those skills where it makes sense. You’re also looking for diversification in anything you’re doing. But truthfully, we’re laser-focused on our current project and the integrity of that asset, that’s No. 1.

We have been fielding, and continue to do so, other opportunities, but we also feel, just like the southern Delaware’s a very natural fi t for what we can do, there will be other opportunities that come up that we can take our executional, operationally focused team and go put those skills to work in another place. It could be the Denver-Julesburg Basin, it could be somewhere in East Texas. We continue to keep looking around for something that naturally fits us. We have our eyes open.

Recommended Reading

CERAWeek: Saudi Aramco CEO Says No Peak in Oil Demand for Some Time to Come

2024-03-18 - Reducing greenhouse gas emissions from hydrocarbons through carbon capture and other technologies achieves better results than alternative energies, Saudi Aramco CEO Amin Nasser said.

NAPE: CCUS is a Risky Venture Hinging on Tech, Regulation, Reservoirs

2024-02-14 - Transdisciplinary collaboration and reservoir understanding are key to mitigating CCUS risks.

Amid Climate Scaremongering, Energy Execs Urge Engagement, Realism

2024-02-06 - From shale boom to net zero goals, industry experts grappled with the contradictions facing the energy industry during SPE’s Hydraulic Fracturing Technology Conference.

CERAWeek: NOCs Balance Financial Realities, Energy Transition

2024-03-21 - National oil companies’ strategies include diversifying energy sources and seeking reserves located deeper in the ground and in deeper waters, while still working to curb emissions.

‘Growth Story’ for Oil: Rice's Kenneth Medlock on Demand Trends

2024-03-05 - Economics drive oil demand, not politics, Rice University’s Kenneth Medlock said during the International Drilling Conference and Exhibition in Galveston.