E&P operators played an important role driving the development of thru-tubing-deployed electric submersible pumps (ESPs), in particular during the last 20-plus years, with important in-house and sponsored initiatives targeting the development of a cost-effective and more efficient ESP deployment alternative. Those initiatives also were designed to improve challenging field developments and economics.

In the late 1990s, a thru-tubing-conveyed ESP/progressive cavity pump (PCP) technology was introduced to overcome Alaska’s West Sak production challenges, which included a rigless ESP/PCP “pump-only” changeout on a live well, saving more than 300 rig interventions over a 20-year period. The success of this firstgeneration tool provided incentives to further develop a fully retrievable thru-tubing ESP with further enhanced functionalities. Among those were rapid ESP changeout on a live well with standard slickline/wireline, reducing deferred production and the ability to maintain flexible ESP component change-out for harsher downhole conditions.

Thru-tubing ESP advancements

In 2014 AccessESP commercialized a rigless thru-tubing retrievable ESP system in which the entire ESP would be deployed and changed out through tubing on a live well, eliminating the need for costly heavy workovers to replace ESPs while improving well production uptime and field development economics.

The development also needed to be compatible with existing ESP infrastructure and equipment and provide fullbore access to the lower completion and reservoir for remedial/intervention work (cleanup, logging, setting plugs, perforating, etc.).

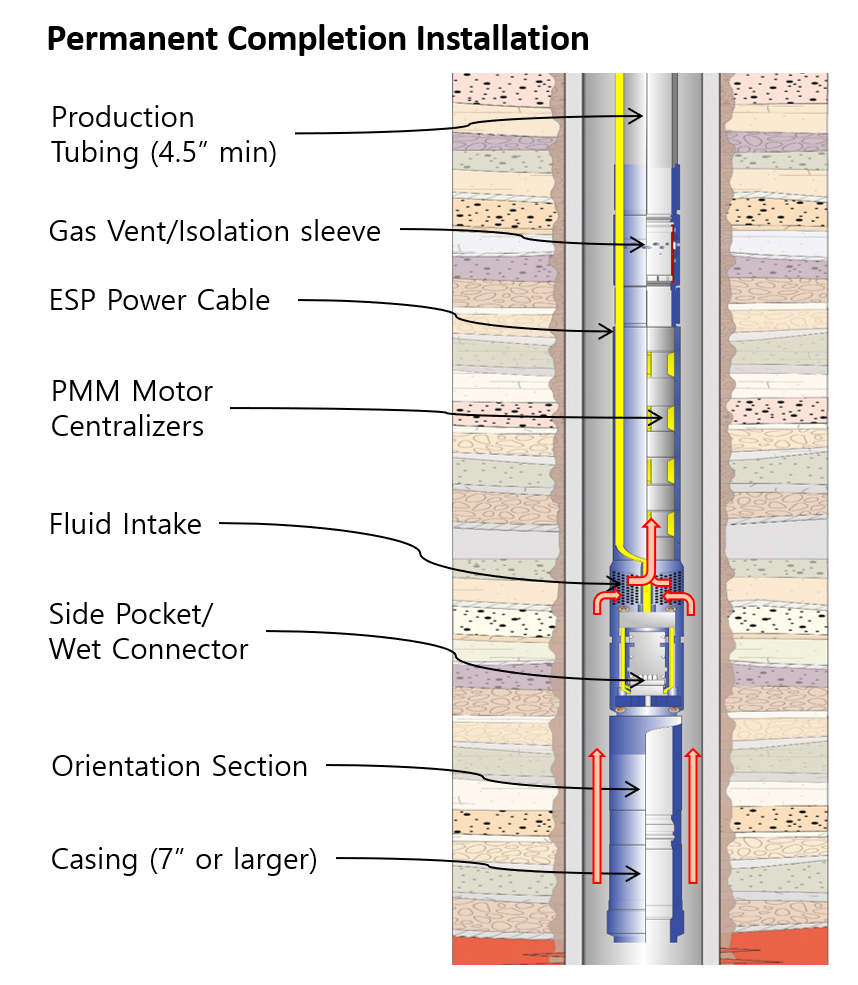

The AccessESP system consists of an outer, permanent completion run with tubing and a retrievable assembly run through tubing. The permanent completion is intended to remain in the well for an extended period of time (10-plus years). Running the permanent completion is similar to running an ESP, with the production tubing and power cable outside of the tubing string.

A side-mounted permanent connector system provides the electrical connection between the power delivery system and the retrievable ESP assembly. The system features a 3.8-in. fullbore access to the lower completion (production zone) once the ESP is retrieved through tubing from the well. An isolation sleeve is available to protect the permanent wet connector dock from mechanical damage during well work operations.

The retrievable ESP assembly includes the ESP components and is designed to be riglessly deployed through tubing with conventional, light intervention equipment on a live well. Strategically, this is installed in four individual runs, a proven deployment method that ensures ease of deployment and removal.

AccessESP’s proprietary permanent magnet motor is one-fifth the weight and length of a conventional ESP induction motor, enabling ESP change-out through a live well standard slickline or wireline operation. In wells with high deviation and depths beyond typical slickline reach, the system has been successfully deployed using coiled tubing (CT), wireline tractor or pump-down.

AccessESP, along with two major E&P operators, developed the Encapsulated Power Cable (EPC) targeting the elimination of ESP cable and connector failures for up to 20-year completion life. The EPC is environmentally resistant with no conductor insulation exposure to well fluids, features high crush resistance and mechanical strength, and is suited for deviated wells. Oil-filled, pre-installed connectors ensure full system reliability, reducing system installation time.

Documented cases

AccessESP technology helps the industry operate safer and more efficiently. Shared cases include Society of Petroleum Engineers (SPE) and industry publications:

ESP pump-only replacement (SPE-193783 and SPE-194419 papers): This case discusses a thru-tubing pump-only replacement with slickline on a live well with the motor remaining in the well. The application is for wells exposed to excessive sand production affecting equipment life.

Rigless well cleanout, well sanded-up (SPE-193652): This case discusses a live well cleanout operation to restore production on a sanded and highly deviated multilateral well with ESP (sand 610 m [2,000 ft] above the ESP). The operation involved CT to clean up the sand and a combination of CT and slickline to pull and reinstall the ESP where a protective isolation sleeve was used to protect wet-connect.

Rigless, live well ESP resizing (SPE-185160): The well’s productivity was found to be higher than estimated requiring system upsizing in power and capacity. The ESP system was replaced using slickline in days rather than months as compared to a conventional ESP.

Rigless, live well ESP change-out to correct well problems (SPE-194412): An ESP was horizontally placed on a small offshore platform with a limited footprint and was diagnosed with developing recirculation downhole. The well was put back in full production by replacing the pack off with slickline and well tractor using a compact mast.

Emerging applications and operating practices

Operators can switch gas-lifted wells to ESPs, in particular for offshore and remote applications, achieving higher drawdown and well productivity and maintaining opex, while increasing field economic life.

In addition, reducing risks, operating time and unnecessary costs, thru-tubing ESPs can optimize flowback/ cleanout operations. For wells left on natural flow, the ESP is removed riglessly, leaving the flow path uninterrupted. If needed, the ESP is reinstalled riglessly through tubing.

Conclusion

Thru-tubing retrievable ESP offers a proven ESP deployment option. AccessESP technology, including its Power Delivery System enables the industry to produce remote and offshore fields, lowering breakeven costs more economically.

AccessESP technology has been successfully deployed globally addressing concerns related to the unfavorable impact caused by ESP failures and associated change-out costs as well as production deferral from well downtime.

Thru-tubing retrievable ESP technology should be considered as part of a new field development FEED phase, potentially a cost-effective and economic solution in particular for offshore platforms and remote locations. AccessESP is successfully operating rigless ESPs in onshore remote wells as well as on small West Africa and Asia platforms through a light intervention.

Recommended Reading

TC Energy’s Keystone Back Online After Temporary Service Halt

2024-03-10 - As Canada’s pipeline network runs full, producers are anxious for the Trans Mountain Expansion to come online.

Post $7.1B Crestwood Deal, Energy Transfer ‘Ready to Roll’ on M&A—CEO

2024-02-15 - Energy Transfer co-CEO Tom Long said the company is continuing to evaluate deal opportunities following the acquisitions of Lotus and Crestwood Equity Partners in 2023.

Waha NatGas Prices Go Negative

2024-03-14 - An Enterprise Partners executive said conditions make for a strong LNG export market at an industry lunch on March 14.

Enbridge Announces $500MM Investment in Gulf Coast Facilities

2024-03-06 - Enbridge’s 2024 budget will go primarily towards crude export and storage, advancing plans that see continued growth in power generated by natural gas.

TC Energy's Keystone Oil Pipeline Offline Due to Operational Issues, Sources Say

2024-03-07 - TC Energy's Keystone oil pipeline is offline due to operational issues, cutting off a major conduit of Canadian oil to the U.S.