Schlumberger’s Performance Live service provides customers with instant access to data and collaboration with domain experts, optimizing remote wellsite operations control while improving safety, efficiency and footprint. (Source: Hart Energy; Schlumberger Ltd.)

[Editor's note: A version of this story appears in the September 2020 edition of E&P Plus. Subscribe to the magazine here.]

Digital service delivers real-time operational data and insights

Schlumberger has released its Performance Live digitally connected service that optimizes remote wellsite operations control while improving safety, efficiency and footprint. The service includes technology and domain expertise within a digital ecosystem, leveraging cloud-based applications and automated data workflows through a secure and robust data network. The Performance Live service provides customers with instant access to data and collaboration with domain experts, enabling faster, more informed decision-making for directional drilling, well logging, formation testing and other oil and gas operations. Automated end-to-end workflows simplify tasks that eliminate redundancy and deliver consistent service.

Software monitors workers’ safety in real time

Honeywell has released Safety Suite Real Time, new software to help industrial facility operators and safety managers monitor workers’ exposure to gas, weather and certain physiological conditions in real time to help prevent incidents and quickly respond to emergencies. The software, which integrates into plant operations, connects wirelessly to gas detection devices to enable centralized monitoring of assets and workers. The software is designed to help eliminate manual processes, assist with regulatory compliance, maximize accuracy and efficiency, and minimize safety costs. Safety managers can use the platform to monitor workers on the job site and view gas readings, alarms, compliance statuses and more on a map-based display viewable from the command center or any internet-connected device. Safety managers can track live situations as they occur, determine personnel locations and detect issues early to help avoid bigger problems and instantly notify workers via SMS messaging to clear the area.

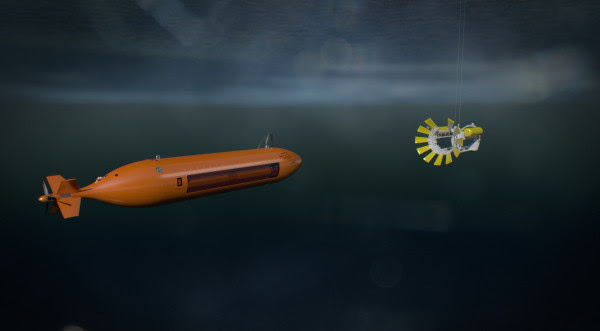

New system increases efficiency, improves safety of AUVs

Kongsberg Maritime has released the Launch and Recovery System (LARS) for its HUGIN range of AUVs. After evaluating techniques and procedures in depth, Kongsberg Maritime developed an optimal solution to have the LARS operating from midships, with the release and capture of HUGIN marine robots occurring beneath the sea surface. Launching and recovering AUVs under water, away from the splash zone, lessens the possibility of damage, while midships deployment averts any likelihood of AUVs being run over by the launch vessel. An added benefit of the LARS’ subsea capabilities is that the launch and recovery processes can be carried out in much higher sea states, reducing the risk of weather damage to marine robots, while also boosting productivity to deliver significant cost savings. The design allows AUVs to be deployed from a hangar or container, and multiple robots may be managed from a single LARS.

Online program offers on-demand well control training

Well Control School has launched the SMART knowledge retention program, a new online well control training aid designed to give learners access to exclusive curriculum through a web-based subscription service. SMART delivers more than 400 individual training videos with customizable programs that cover every learning objective required by industry standards. The SMART library allows subscribers to easily review missed objectives at their own pace by using a keyword system linked to specific training goals. The program also gives training administrators complete control of assembling multiple micro-courses while coaching and evaluating individual learners in real time to ensure an optimal outcome whether they are in the oil field or the classroom. The SMART program is designed for individual companies, university petroleum engineering programs, government agencies and insurance companies focused on oilfield coverage.

Educational web series focuses on proppants

Hexion Oilfield Technology Group has launched Proppant Talk, an educational web series posted weekly on their LinkedIn showcase page. The short videos are focused on proppant-related issues in hydraulic fracturing. Topics covered include proppant flowback, fines generation and migration, effects of cyclic stress and more. Hexion has been releasing these videos to keep members of the industry informed and entertained during the COVID-19 crisis and downturn in oilfield activity.

Updated versions of reservoir characterization software enhance the user experience

CGG GeoSoftware has released new versions of its cloud-ready reservoir characterization and petrophysical interpretation software. All applications across the entire GeoSoftware portfolio now run on both Azure and AWS platforms. The newest releases, Jason 10.1, Hampson-Russell 10.5 and PowerLog 10.1, also offer advances in machine learning and artificial intelligence (AI) as well as streamlined connections to Python ecosystem notebooks.

Jason 10.1 enhancements include further expansion of the drag-and- drop functionality of files and viewers. The Jason Workbench offers a consolidated Progress Overview, an all-in-one window without distracting popups. Time-to-depth conversion in Jason DepthMod is faster and requires fewer steps. Velocity refinement can occur over all geologic layers simultaneously.

HampsonRussell 10.5 offers multinode processing (MNP) on Windows in addition to Linux, powerfully speeding up processing projects. Initial tests of MNP Windows indicate 3.5 times faster project speeds when using four MNP nodes rather than a single node.

PowerLog 10.1 offers Automatic Depth shifting, an AI capability that calculates depth shifts for a variety of well log datasets to a measurement that is known to be on depth, important for generating log correlations and valid petrophysical computations. Many of PowerLog’s usability enhancements are client-driven and enable users to easily generate interpretations and optimize well completions.

In-bit sensors deliver performance measurements to maximize drilling efficiency

Halliburton Co. has released its Cerebro Force in-bit sensors that capture weight, torque and bending measurements directly from the bit to improve understanding of downhole environments, optimize bit design and increase drilling efficiency. Built on Halliburton’s in-bit vibration sensing platform, Cerebro Force utilizes downhole data to reduce or eliminate surface measurement uncertainty and inefficiencies caused by bit design, bottomhole assembly and drilling parameter selection. Through the Design at the Customer Interface (DatCI) process, Halliburton’s local network of drill bit experts collaborate with operators to customize bits for basin-specific applications and will use data from Cerebro Force to inform new designs and optimize parameters for efficient and precise drilling.

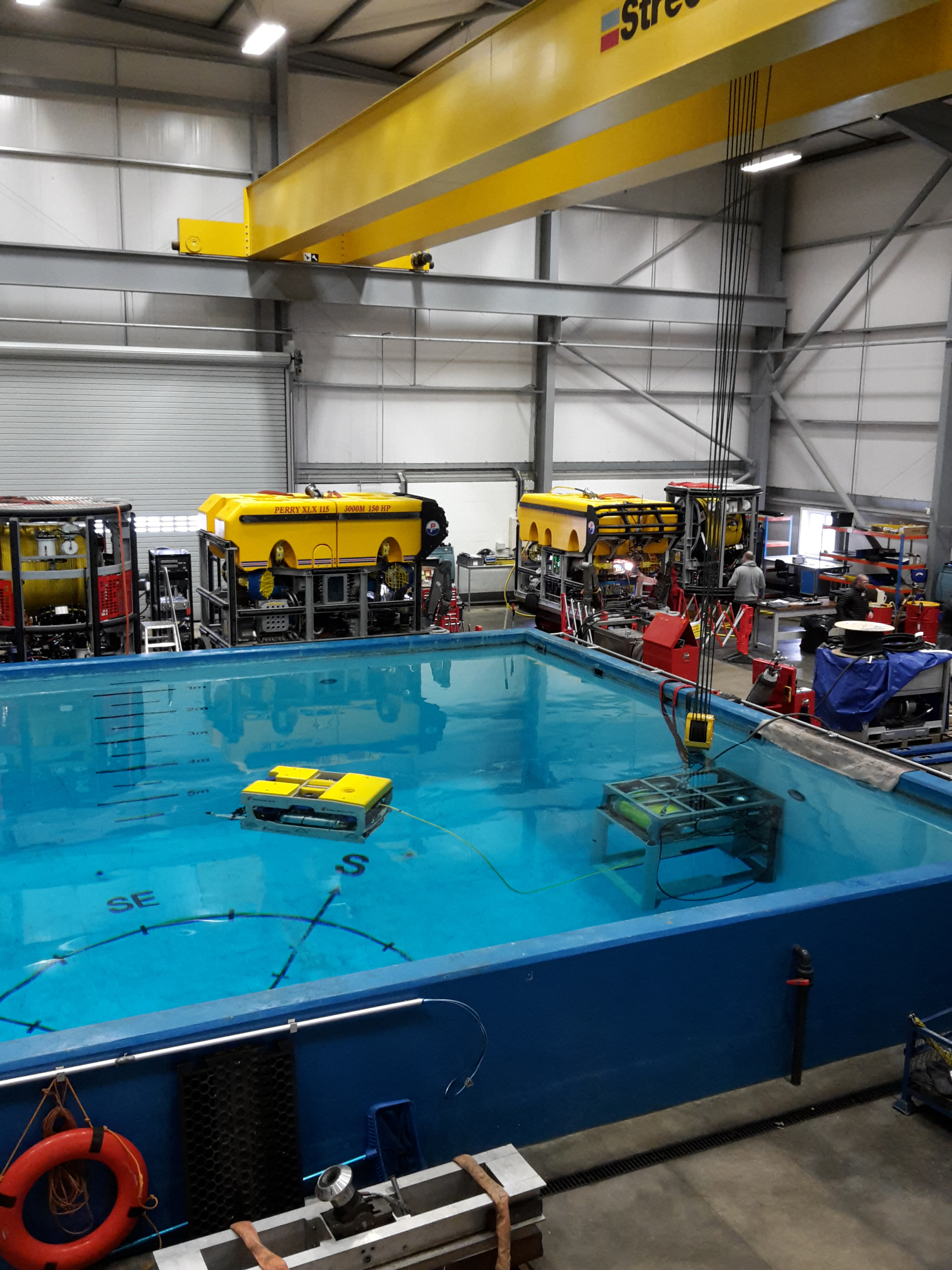

Remote piloting capability for ROVs

Forum Energy Technologies has developed and demonstrated the ability to remotely operate work- class and observation class (Perry and Sub-Atlantic) ROV systems between an offshore vessel and a remote location. This new capability brings major opportunities to adapt operational practices in response to the latest industry drives as cost savings and reductions in HSE risks can be realized through reducing offshore crew sizes. Continued development in software efficiencies, which reduce the effect of network latency coupled with increased availability and reliability of the global 4G network, has now allowed Forum to offer remote operations on its full range of ROV systems. Forum’s ICE and subCAN remote operations suites provide a robust means of piloting vessel or platform-based systems from an onshore control facility via a wired, 4G or satellite connection.

Editor’s note: The copy herein is compiled from press releases and product announcements from service companies and does not reflect the opinions of Hart Energy. Submit your company’s updates related to new technology products and services to Faiza Rizvi at frizvi@hartenergy.com.

Recommended Reading

Nel Realigns Supply Agreement with Nikola, Supplies Fortescue

2024-02-02 - Nel ASA and Nikola Corp.’s new supply agreement is for 110 alkaline stacks and related balance of stack equipment.

Verdagy Awarded $39.6MM DOE Grant for Electrolyzer Production

2024-03-14 - Verdagy will use the Department of Energy grant to accelerate the manufacture of e-dynamic electrolyzers for green hydrogen solutions.

Energy Transition in Motion (Week of March 8, 2024)

2024-03-08 - Here is a look at some of this week’s renewable energy news, including a record-setting 2023 for U.S. solar.

First Solar Gunning for $1B More in 2024 Sales

2024-02-28 - Solar module manufacturer First Solar forecasts 2024 net sales of between $4.4 billion to $4.6 billion, with annual volumes sold ranging from 15.6 gigawatts (GW) to 16.3 GW.

Solar Panel Tariff, AD/CVD Speculation No Concern for NextEra

2024-04-24 - NextEra Energy CEO John Ketchum addressed speculation regarding solar panel tariffs and antidumping and countervailing duties on its latest earnings call.