(Source: Acoustic Data)

[Editor's note: A version of this story appears in the June 2020 edition of E&P. Subscribe to the magazine here. It was originally published June 1, 2020.]

Remote training for offshore vessels

Kongsberg Maritime offers virtual, targeted training through digital platforms including remote training, e-learning and the Kongsberg Competence Assessment Tool (K-CAT). Video conferencing and virtual machines allow in-depth, hands-on training to be safely delivered, maintaining skills and continuing development. The virtual training environment enables remote students to learn using their own vessel’s software, assisted live by a qualified instructor. Remote training delivered through established virtual classrooms and online training tools will ensure that vessel crews can fully benefit from Kongsberg’s expertise from the convenience and safety of their homes or offices. E-learning delivers an interactive experience without the instructor, allowing the student to complete the course at their convenience. E-learning typically comprises a combination of theoretical lessons, practical tasks and summative tests after every topic, qualifying the student to sign up for a final online assessment. Aiming to help ship owners safeguard and verify the development and retention of their crews’ skills, K-CAT offers competence assessments for key damage prevention personnel, with additional offerings expected soon.

New system for remotely monitoring drilling operations

Stress Engineering Services (SES) has released a digital flex joint angle measurement system for monitoring real-time drilling operations. Using the core technology of a real-time fatigue monitoring system and subsea vibration data logger system, the technology has been leveraged and improved to determine quasi-static and dynamic lower and upper flex joint angles in real time. The development adds to the company’s present technology portfolio of asset-based surveillance systems, together with its predictive data analytics and Internet of Things ecosystem, to manage and assess client operations. The enhanced level of services provided by this system during drilling operations will vastly benefit those with a stake in identifying and managing risks and any asset deterioration.

Risk management tool to help businesses resume operations smoothly

ABS Consulting has released the Restart Risk Model to help commercial and public organizations resume operations safely as restrictions around the COVID-19 pandemic have started easing. The Restart Risk Model builds on guidance from the Centers for Disease Control and Prevention and OSHA, offering a way for organizations to systematically evaluate the risk of disease transmission to their sites, operations and work areas. This risk-based framework will help organizations develop a plan to restart operations with enhanced working practices that address the “new normal” business environment after the pandemic. The Restart Risk Model leverages industry-specific templates developed by ABS Consulting to assess an organization’s site and develop a custom risk profile. Through a systematic process, the company will work with a client to document current risk controls for worker safety and make recommended mitigation controls for back-to-work scenarios and the opening and closing of sites. The Restart Risk Model also includes an integrated dashboard that provides a visualization of risk levels at work sites. As conditions and guidance evolve, organizations can easily see where they need to adapt.

Device ensures the safety of workers through social distancing

Triax Technologies Inc. has released Proximity Trace devices that provide proximity distancing alerts and contact tracing through a wearable device for workers. The device offers added protection for essential workers during the COVID-19 pandemic and helps companies get workers back to work safely while addressing recommended social distancing practices. The Proximity Trace devices are affixed to a hard hat or worn on the body with a lanyard and emit a progressively louder alarm, alerting workers when they are too close to each other. The alarm also serves to change behaviors by reminding workers to practice safe social distancing. In the event of a confirmed case of COVID-19 in an employee, the employer can conduct contact tracing using historical data captured passively by the worker’s device to identify who may have been exposed. With more reliable information, companies can decide who needs to be in mandatory or precautionary quarantine per the Centers for Disease Control and Prevention guidelines and whether the site can continue to operate safely without the need to shut down the entire operation. Proximity Trace was designed to support appropriate social distancing guidelines as outlined by government agencies, which can be used alongside an organization’s internal policies on social distancing and other safety guidelines. The device communicates to a cloud dashboard designed for contact tracing. The product is undergoing field testing, and key feedback from early customers will be incorporated into production for commercial availability.

3D data capture service for offshore operations

Viewport3 has developed a new remote data capture service, allowing users to collect and process 3D data from offshore operations via remote working arrangements. Demand for the data capture service has grown as operators seek to reduce personnel working offshore, combined with travel restrictions related to COVID-19. The company’s technique involves providing divers and ROV personnel with instructions for the task along with remote support, allowing them to collect and submit the data to Viewport3 for processing and analysis. Over the course of the development, the company has improved the service to ensure users can retrieve the correct data. Because written instructions were insufficient, site-specific video and graphical workflows were created to demonstrate how to collect all the required information. Viewport3 can process and interrogate data acquired from any source, in addition to its own.

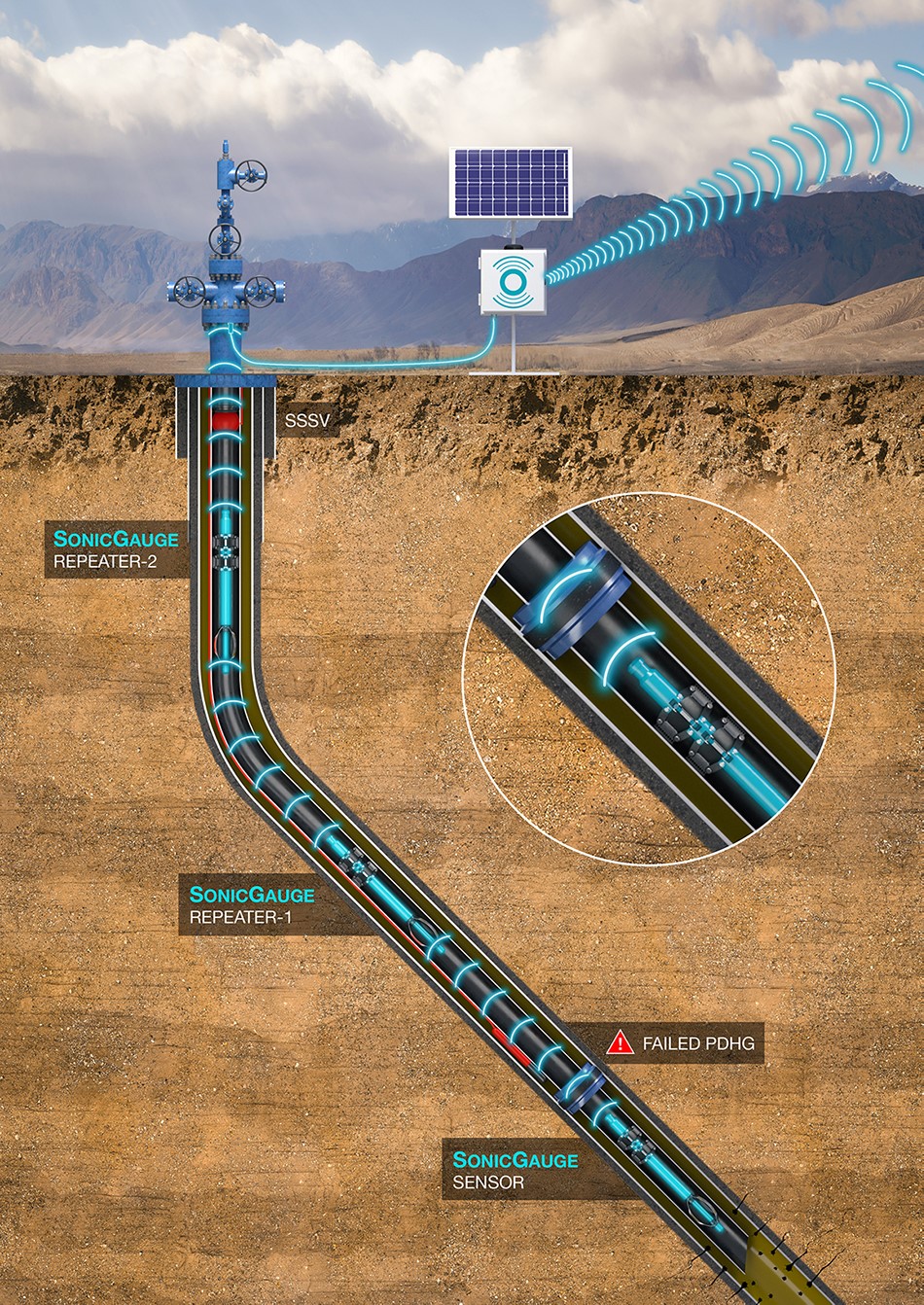

Remote deployment for wireless monitoring system

Acoustic Data has released a remote deployment model for its SonicGauge Wireless Monitoring System to overcome travel restrictions related to COVID-19. The system enables operators to self-install their real-time wireless downhole monitoring system without any specialist engineers on site. With much of the industry’s workforce grounded, Acoustic Data is offering full operational support in real time from its U.K. headquarters. In conjunction with online training videos, operators will now be able to install the prepackaged and preprogrammed technology in standard well installations, from underground gas storage to production and monitoring wells. The SonicGauge provides simple, real-time data acquisition and reporting as an alternative to cabled permanent downhole gauges and sporadic memory gauge surveys. The acoustic telemetry system enables engineers to conduct real-time reservoir evaluation in underground storage, production, injection and monitoring wells. The technology can be quickly and safely retrofitted via slickline in existing wells with Acoustic Data’s Barracuda HEX-Hanger, a high-expansion gauge hanger system.

Editor’s note: The copy herein is compiled from press releases and product announcements from service companies and does not reflect the opinions of Hart Energy. Submit your company’s updates related to new technology products and services to Faiza Rizvi at frizvi@hartenergy.com.

Recommended Reading

Range Resources Holds Production Steady in 1Q 2024

2024-04-24 - NGLs are providing a boost for Range Resources as the company waits for natural gas demand to rebound.

Hess Midstream Increases Class A Distribution

2024-04-24 - Hess Midstream has increased its quarterly distribution per Class A share by approximately 45% since the first quarter of 2021.

Baker Hughes Awarded Saudi Pipeline Technology Contract

2024-04-23 - Baker Hughes will supply centrifugal compressors for Saudi Arabia’s new pipeline system, which aims to increase gas distribution across the kingdom and reduce carbon emissions

PrairieSky Adds $6.4MM in Mannville Royalty Interests, Reduces Debt

2024-04-23 - PrairieSky Royalty said the acquisition was funded with excess earnings from the CA$83 million (US$60.75 million) generated from operations.

Equitrans Midstream Announces Quarterly Dividends

2024-04-23 - Equitrans' dividends will be paid on May 15 to all applicable ETRN shareholders of record at the close of business on May 7.