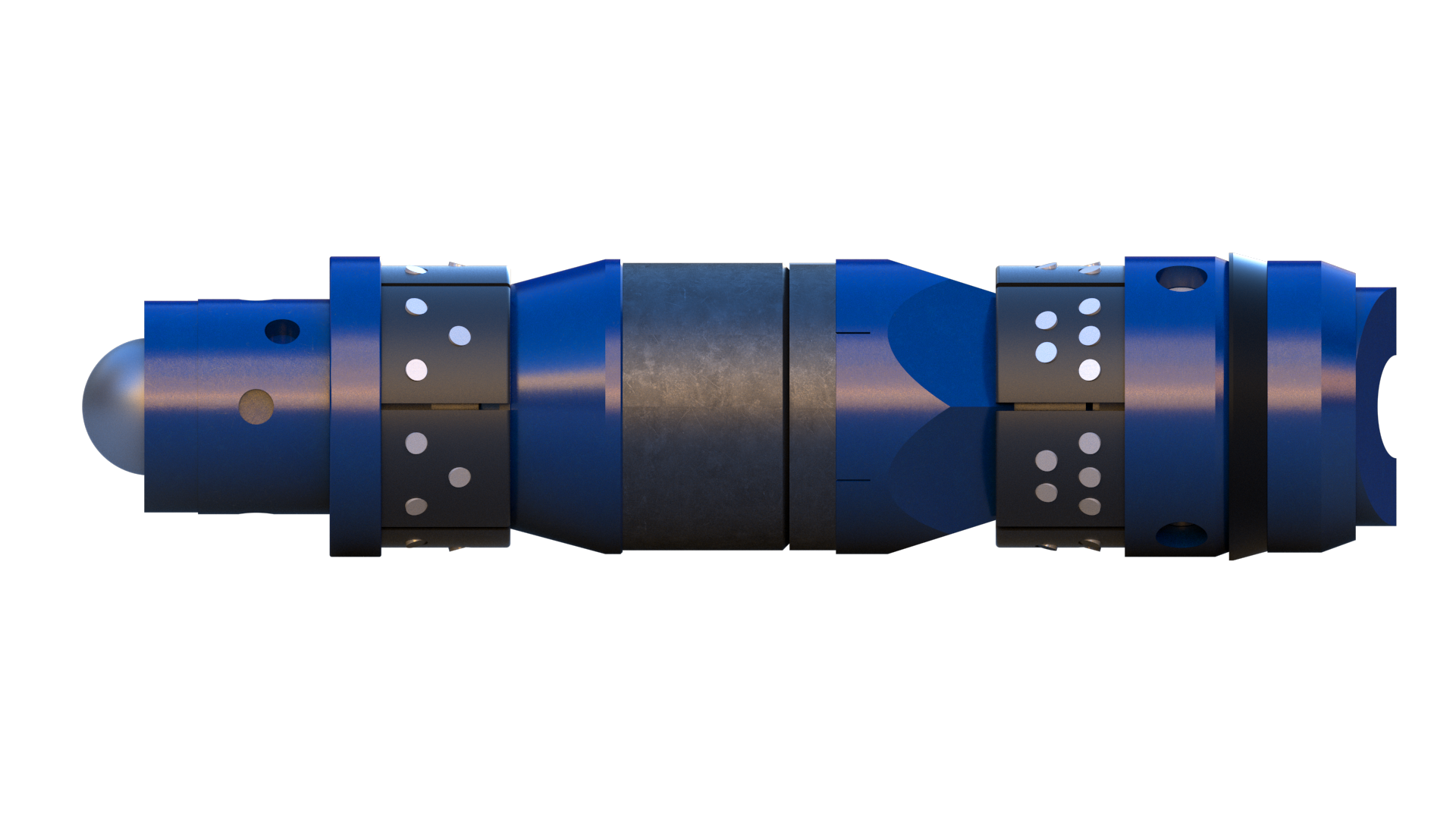

Completion system expedites multizone frack and gravel packs

Completion system expedites multizone frack and gravel packs

To speed up sand control completions in land and offshore wells, Schlumberger offers its MZ-Xpress single-trip multizone frack- and gravel-pack system. After the zones of interest are perforated and the well is cleaned, hardware for all zones is run into the well in a single trip, permitting rapid gravel- or frack-packing. To ensure reliable operations in a wide variety of applications from land to deep water, the system incorporates robust debris management to minimize the risk of malfunctions and nonproductive time during sand control operations. The system also incorporates field-proven modular subassemblies that increase application flexibility in challenging well architectures, including multiple casings. http://www.slb.com

Buoy swivel technology reduces maintenance downtime

Flexible Engineered Solutions International (FES) has developed new technology for a major manufacturer of marine equipment based in China, a press release stated. The CALM Buoy Swivel, which is fully certified by DNV GL, includes new swivel technology that allows the buoy to rotate while maintaining a leak-free joint between the subsea pipelines and vessel during the transfer of fluid. Because it enables the replacement of seals onboard without the requirement to bring the main buoy into a repair yard, the new swivel will significantly reduce maintenance downtime for the CALM Buoy, avoiding it being offline for long periods of time. fesinternational.com

First rigless-deployed ESP system installed

Baker Hughes recently installed the first TransCoil rigless-deployed electric submersible pumping (ESP) system, which is designed to help operators bring wells on production faster and lower the costs associated with installing and replacing ESPs, the company said. Because they can eliminate the need for a rig in fields where rig availability is a concern or where high intervention costs can limit artificial lift options, operators can minimize deferred production and lower their overall lifting costs to extend the economic life of their assets. The TransCoil system developed in participation with Saudi Aramco features an inverted ESP system with the motor connected directly to a new proprietary power cable configuration, eliminating the traditional ESP power cable-to-motor connection. Unlike wireline-deployed ESPs, the fully retrievable TransCoil system does not have an in-well “wet connection” that requires a rig to pull and replace if the wet connection fails. The TransCoil system was installed and commissioned in a well at 1,493.5 m (4,900 ft) in 7-in. tubing in Saudi Aramco’s Khurais Field. The rigless operation reduced installation time nearly 50% over a rig-based installation, and further deployment efficiency improvements are expected in the future. bakerhughes.com

New technology to dehydrate natural gas

ExxonMobil’s development of cMIST technology dehydrates natural gas using a patented absorption system inside pipes and replaces the need for conventional dehydration tower technology, a press release stated. This “in-line” technology could be deployed at land-based and offshore natural gas production operations. The new technology, developed and extensively field-tested by ExxonMobil, more efficiently removes water vapor present during the production of natural gas. Removing water vapor through the use of dehydration technology, typically accomplished using large and expensive dehydration towers, reduces corrosion and equipment interference and helps to ensure the safe and efficient transport of natural gas through the supply infrastructure and ultimately to consumers. cMIST is designed to reduce the size, weight and cost of dehydration, resulting in reductions of surface footprint by 70% and the overall dehydration system’s weight by half. exxonmobil.com

Reservoir modeling capabilities maximize recovery

Emerson Automation Solutions has released the Roxar API (Application Programming Interface), a press release stated. This extensibility interface is designed for reservoir modeling and, in particular, for the company’s software Roxar RMS. Roxar API helps operators customize their workfl ows to achieve specific goals, improves data management capabilities with greater interoperability and fl exibility, preserves vital reservoir information across multiple-stage workfl ows and enables users to analyze and visualize their models in different and innovative ways for improved reservoir interpretation and increased recovery. Using Python, a powerful but simple-to-use programming language, the Roxar API enables operators to integrate their own intellectual property into reservoir modeling workfl ows. In addition, applications can be written or extended to access RMS project data. emerson.com

Drillbit technology increases toolface control

Halliburton has released its Cruzer depth-of-cut rolling element, which is a drillbit technology designed to increase toolface control without reducing drilling efficiency, a company announcement stated. This technology provides operators with the ability to increase their ROP at a lower cost per foot for improved economics. Halliburton drillbits are developed through a proprietary process called Design at the Customer Interface (DATCI), which customizes each bit for an operator’s specific application. DATCI employs a global network of design specialists who are familiar with regional characteristics and collaborate with customers for optimized solutions. halliburton.com

Ice charting capability for weather forecasting

Ice charting capability for weather forecasting

BMT ARGOSS (BMT), a subsidiary of BMT Group, has released its ice charting capability, which coupled with its extensive weather forecasting expertise will provide a more enhanced and cost-effective service to customers globally, a press release stated. As part of this new capability, a number of BMT’s key senior meteorologists have completed an intensive training program at the Danish Meteorological Institute. BMT’s Mark van der Putte, who took part in the training, said, “The training has allowed us to better understand the ice regime, i.e., how ice builds up, how it moves and reacts, and how it evolves during the season. Interpreting satellite images is also a key requirement for delivering an effective output. The ice buildup and movement is very dependent on the weather; therefore, our extensive meteorological knowledge and experience will help us to further improve the service we provide.” bmtargoss.com

Rigless system enables ESP pump swap

AccessESP has showcased its rigless electric submersible pump (ESP) conveyance system in the industry’s first pump swap for an operator on the North Slope of Alaska, a press release stated. In two days through a live well intervention the AccessESP system enabled retrieval of the existing ESP pump and the install of a newly optimized ESP using only a slickline unit, lubricator and a crane, marking the industry’s first ESP pump swap on a commercial well. Surface diagnostics determined that the Access375 permanent magnet motor was fully functional; therefore, replacement was not required, thus reducing operational time and costs. In this case, the ESP pump had not failed but was proactively replaced with an optimized pump. This would be cost-prohibitive using a workover rig, requiring the replacement of the entire conventional ESP system. To resize a conventional ESP pump, the operator would mobilize a workover rig, kill the well, pull the tubing and ESP, and then replace the ESP and rerun the tubing. The costs associated with the intervention and downtime inherent in this approach can be substantial. However, by using a standard slickline unit, lubricator and crane, the AccessESP rigless conveyance system reduces the cost, time and risk associated with ESP resizing. AccessESP.com

Companies collaborate to offer asset integrity management

Honeywell and Dover Energy Automation plan to collaborate as part of the Honeywell INspire program, which is Honeywell’s joint customer development program for its Industrial Internet of Things (IIoT) ecosystem. The program is designed to help industrial energy customers improve the safety, efficiency and reliability of their operations, a press release stated. Honeywell’s capabilities in data consolidation, cybersecurity and software development combine well with Dover’s deep domain knowledge in condition monitoring and asset optimization to offer a robust IIoT ecosystem that is designed to help customers solve previously unsolvable problems. The goal is a simpleto- use infrastructure that gives users secure methods to capture and aggregate data so that they can be leveraged by using analytics and applying a range of domain knowledge from a vast ecosystem of equipment vendors and process licensors. With a larger consolidated dataset, manufacturers can apply higher analytics for more detailed insights, scale the data as needed to meet the varied needs of single-site or enterprisewide operations and leverage a wider pool of data experts for monitoring and analysis. dovercorporation.com, honeywell.com

Daily valuations for MODUs

Daily valuations for MODUs

VesselsValue, an online valuation provider, is releasing daily valuations for mobile offshore drilling units (MODUs), a press release stated. This new vessel type is part of VesselsValue’s recent push into the offshore space. In May 2016 VesselsValue released daily updated market and demolition values for 6,500-plus offshore support vessels. The new vessel types, which are available on the VesselsValue website, comprise 1,020 individual MODUs (including drillships, semisubmersible units and jackups) and can be presented via company fleets and portfolios. To arrive at daily valuations, VesselsValue uses a complex algorithm that considers the full specifications of the vessel (age, size, ship type and features) as well as the recent spot rates, secondhand sales, newbuilding prices, oil pricing and other market indicators. These data are made available for VesselsValue clients through the VesselsValue Deals database. VesselsValue.com

Closeable system reduces time, costs

Packers Plus Energy Services Inc. recently worked with an operator in Egypt to complete a six-stage StackFRAC system using the drillable closeable (DC) FracPORT sleeve in a short time frame, a press release stated. “Packers Plus’ advanced manufacturing capabilities ensured the product was delivered and tested within three days, meeting the client’s operational timeline and technical requirements,” said Packers Plus President Ian Bryant. “Not only was the client working in a short turnaround time, they also were interested in a closeable system that would simplify future operations.” The openhole approach was chosen over the plug-and-perf method to shorten operational time, simplify operations and reduce overall cost. The DC FracPORT sleeve is a ball-actuated hydraulically activated injection/production port. The closeable feature of the sleeve provides the operator with options to shut off water encroachment if required, reducing operational costs and optimizing production performance. The operation, installation and completion—done in conjunction with Packers Plus’ global marketing alliance partner, Schlumberger— were executed according to plan. Additional systems were planned for late 2016. packersplus.com

Hydrogen sulfide detector for arid locations

Tyco Gas & Flame Detection’s DG-TT7-S hydrogen sulfide (H2S) gas detector with a metal oxide semiconductor sensor underwent stringent functional safety assessments by an external certification body and is now SIL 2 approved, a press release stated. The DG-TT7-S gas detector is used mainly for the detection of H2S in arid locations having air present or in locations with continuous H2S background. The sensor specifies a wider continuous operating temperature range than the standard electrochemical sensors up to +65 C (+149 F). The MultiTox DG-TT7-S features onboard relays, plug-and-play sensors and a highly visible display that changes color depending on the status mode. TycoGFD.com

Dust suppressant provides safety from sand mine to wellhead

The Oilfield Technology Group of Hexion Inc. has released its Sentinel dust suppressant, a press release stated. This new technology is designed to reduce dust generated from uncoated fracture sand. The Sentinel dust suppressant is designed to reduce the amount of respirable silica to levels below the new Occupational Safety and Health Administration and existing Canadian permissible exposure limits. The dust suppressant is capable of reducing respirable silica dust below 25 μg/cu. m. The chemical system traps fine dust particles and remains on the proppant during transportation and transfer. This liquid dust control agent is effective on all mesh-size sands. The Sentinel dust suppressant helps provide safety and compliance from the sand mine to the wellhead. The versatile application method allows users to apply the product at the sand mine, transload or at the fracture site. The delivery system can be mobile or stationary and has a small footprint on location. It will not decrease throughput at the sand mine or decrease sand offl oading time when deployed at a transload or fracture site. hexion.com/oilfield

Composite fracture plug for zonal isolation

Composite fracture plug for zonal isolation

TEAM Oil Tools has developed the TOMCAT fully composite fracture plug, an addition to the TOMCAT product line, a press release stated. The TOMCAT fully composite fracture plug uses high-strength composite components to provide a dependable, durable and cost-effective design for zonal isolation during multistage completions. These fracture plugs are constructed of machined composite material with composite upper and lower slips. The plug is compact in length with zero metal components and has pumpdown kits that allow 500-plus feet-per-minute run in speed. The specialized design features ceramic buttons that do not damage the mill/bit bodies during plug drill-outs. teamoiltools.com

Online intelligence resource provides data analytics

Online intelligence resource provides data analytics

Douglas-Westwood has released Sectors, a service that provides access to core and previously unavailable data, a company announcement stated. A brand new online data analytics subscription service, Sectors enables users to interrogate, screen and visualize oilfield intelligence from anywhere in the world. The first Sectors module focuses on the global drilling and production sectors, with additional modules to be rolled out through 2017. The service enables users to build bespoke charts and export data using global, regional, country and field-level filters with multiple attributes. Users can keep track of the market, have visibility to current and future movements, quantify and qualify strategy and planning assumptions, identify key questions to challenge investment decisions, or triangulate internal and third-party data. The online subscription service, Sectors, launched Jan. 24. douglas-westwood.com/sectors

Simplifying offshore asset maintenance

Two new coatings, Hempadur Quattro XO 17820 and 17870, have been released by Hempel to increase the service life and reduce on-station maintenance requirements of offshore assets, a press release stated. The high-performance pure epoxy uni-primers combine corrosion protection with construction flexibility. Hempadur Quattro XO 17820 and 17870 are part of a series of two-component epoxy primer coatings that provide advanced crack resistance using Hempel’s patented fiber technology. They can be applied in immersed and nonimmersed areas of any offshore asset, from offshore platforms and drilling rigs to support vessels. Their high-volume solids ratio (80%) means that fewer volatile organic compounds are released into the atmosphere. Hempadur Quattro XO 17820 and 17870 can be applied to multiple areas above and below the waterline, including ballast water and oil cargo tanks, and also can be applied year-round with workability from -10 C (14 F) to 45 C (113 F). hempel.com

HP/HT electrical connector reduces downtime, system costs

HP/HT electrical connector reduces downtime, system costs

Rampart Products has specified the VICTREX HT polymer for a new HP/HT KTK (aka Kintec) electrical connector for the efficient and safe transmission of power and data during the drilling process, a press release stated. Used in oilfield equipment, the reliability of the multi-pin connector is crucial to reducing costly downtime. The material as well as the connector has been tested beyond industry standards in real-world environment simulations. During material selection and the development of the molding process Rampart and Victrex worked together, enabling Rampart to release its first connector using the VICTREX PAEK (polyaryletherketone) polymer. The new connector has been rated for temperatures beyond 200 C (400 F) and pressures at 20,000 psi, providing a reliable electrical connection while protecting expensive sensors and electronics. rampartproducts.com, victrex.com

Please submit your company’s updates related to new technology products and services to Ariana Benavidez at abenavidez@ hartenergy.com.

Recommended Reading

Wayangankar: Golden Era for US Natural Gas Storage – Version 2.0

2024-04-19 - While the current resurgence in gas storage is reminiscent of the 2000s —an era that saw ~400 Bcf of storage capacity additions — the market drivers providing the tailwinds today are drastically different from that cycle.

Ozark Gas Transmission’s Pipeline Supply Access Project in Service

2024-04-18 - Black Bear Transmission’s subsidiary Ozark Gas Transmission placed its supply access project in service on April 8, providing increased gas supply reliability for Ozark shippers.

Kinder Morgan Sees Need for Another Permian NatGas Pipeline

2024-04-18 - Negative prices, tight capacity and upcoming demand are driving natural gas leaders at Kinder Morgan to think about more takeaway capacity.

Scathing Court Ruling Hits Energy Transfer’s Louisiana Legal Disputes

2024-04-17 - A recent Energy Transfer filing with FERC may signal a change in strategy, an analyst says.

Balticconnector Gas Pipeline Will be in Commercial Use Again April 22, Gasgrid Says

2024-04-17 - The Balticconnector subsea gas link between Estonia and Finland was damaged in October along with three telecoms cables.