Service enables users to deliver single-source start-to-finish CRI solutions

M-I SWACO has released its iWISE integrated waste injection services, a comprehensive single-sourced drilling waste management solution that is cost-effective and can substantially reduce operational risks, the company said. In environmentally sensitive regions, especially for remote locations, cuttings reinjection (CRI) can be a cost-effective, comprehensive option for drilling waste management that meets or exceeds the most stringent environmental standards. Limiting the risks and achieving the unequaled benefits of CRI requires surface and subsurface engineering analysis and diagnostic expertise— before, during and after the operation. iWISE services include field-proven CRI technologies and expertise, workflows and real-time monitoring in one comprehensive service that enables users to deliver single- source start-to-finish CRI solutions on time, on budget and within environmental constraints. slb.com

Downhole density measurements help optimize wellbore placement

Sperry Drilling, a Halliburton business, has released the 9-½-in. Azimuthal Lithodensity (ALD) service, providing real-time density measurements and images in boreholes up to 17½ in. With this addition Halliburton offers the greatest range of hole-size capability and is the only service company to provide this larger wellbore measurement, a press release stated. ALD provides downhole density measurements, including high-quality borehole image logs, to help optimize wellbore placement through geosteering and to reduce geological uncertainties. The measurements, delivered via LWD, also eliminate costly wireline conveyance runs and capture data immediately after drilling when the borehole is in the best condition. The 9½-in. ALD provides the same functionality as its smaller counterparts, including azimuthal density and photoelectric and acoustic standoff measurements. This information has a wide range of applications that can help determine a formation’s porosity, rock strength, pore pressure and borehole geometry. halliburton.com

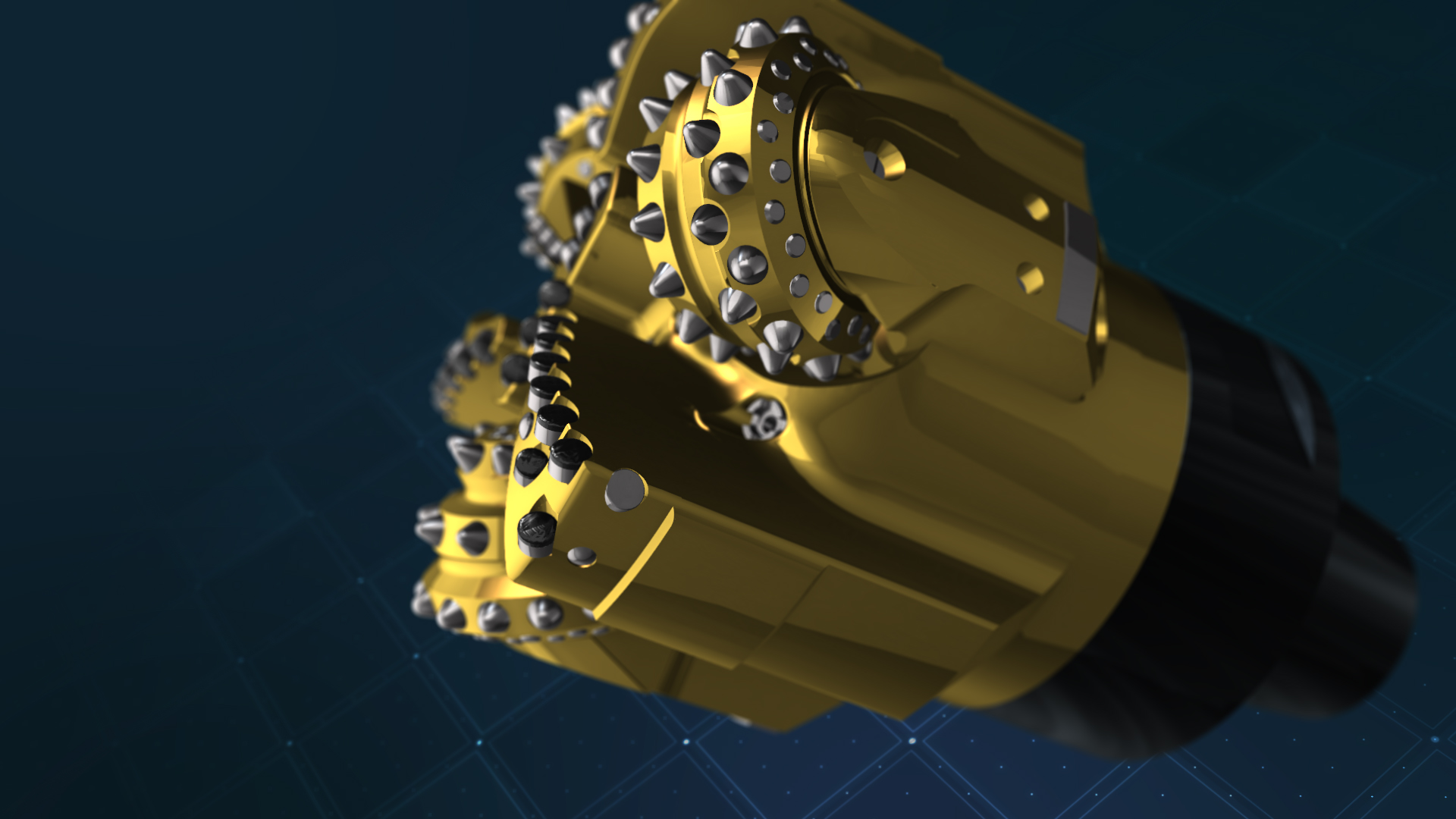

Drillbits improve economics in vertical, curve drilling applications

Baker Hughes has released its line of Kymera XTreme (XT) hybrid drillbits, a press release stated. The bits—which combine the strengths of polycrystalline diamond compact and tricone bit technology—offer the smooth, consistent performance of previous generations of hybrid bits while improving penetration rates and runlife. Kymera XT drillbits are available in a variety of designs, each capable of addressing specific challenges in numerous applications, formation types and hole sizes. The Kymera XT bits drill much faster than previous generation hybrid bits and offer a dynamic balanced design that reduces torque fluctuations to minimize damage to the bit and deliver efficient, effective performance in both vertical and curve sections. They also offer greater steerability and control in difficult environments, including carbonates and interbedded formations. The Kymera XT bits’ sharper, more durable cutting structures incorporate enhanced shapes and carbide grades for improved aggressiveness and accelerated penetration rates. These advanced designs provide added toolface control, enabling the drilling of longer distances at higher buildup rates than was previously possible while maintaining a high-quality borehole throughout extended runs. bakerhughes.com

Automated shear history simulator simplifies fracturing fluid analysis

The Chandler Engineering Model 5600-Auto Shear History Simulator simplifies the process of preparing and loading water-based fracturing fluids into rotational viscometers, according to a press release. Shear history simulators have proven especially useful for determining how well fracturing fluids perform in transporting proppants. The process begins with a gel-based fluid that is placed into a pressurized supply reservoir that delivers the fluid to an injection pump. The fluid is pumped through a combination of tubes at various rates and durations to simulate pumping conditions experienced during fracture treatments. Pressure is applied to the reservoir via an air regulator mounted onto the face panel. The gel pump is constructed of high-pressure corrosion-resistant stainless steel and is driven by a servo motor that can deliver 0 ml/min to 140 ml/min. An additional stainless-steel HPLC additive pump is able to deliver 20 ml/min of Crosslinker. The Model 5600- Auto features 2,000-psi maximum operating pressure at ambient temperatures including multiple tubing configurations, four shear history tube assemblies, convenient manifold connection to a Model 5550 viscometer and a panel-mounted computer with touchscreen interface and automatic loop-flushing features. chandlereng.com

Pressure pump designed to achieve higher flow rates with less pulsation

JJ Tech has released the Hydra-Cell Q155 medium pressure pump for production, according to a press release. The Q155 medium pressure pump is a five-cylinder version of the Wanner T100 three-cylinder pump. The addition of two more cylinders allows the pump to achieve higher flow rates with less pulsation. The Q155M is the fourth model to be tested in a series of high-horsepower field tests implemented by JJ Tech. The first Q155M alpha field test pump was placed into production in March 2015 and was followed quickly by two additional field test pumps. All three test pumps were paired with JJ Tech 2.5 Select Jet Pumps and ran successfully for more than a year in the field before production models were released. j-jtech.com

World’s longest stroke rod lift system designed

Sure Stroke Intelligent Lift Systems (SSi), a Tundra Process Solutions Co., has completed design and construction of the longest stroke-length artificial lift system in the world, according to a company press release. The newly released SSi Model 350 reciprocating rod pump system is capable of handling peak polish rod loads up to 35,000 lb at a 372-in. stroke length. At full load the unit can operate at more than six strokes per minute. The SSi system’s ultralong stroke and adjustable-speed operation will allow oil producers to obtain desired pump production at low peak loads with fewer cycles. The operational lifespan of the rod system and downhole pump is extended while tubing wear is mitigated. As a result, total power required to produce equivalent fluid volumes is reduced. The SSi system also is not wellhead-mounted, so readiness for workover requires no cranes or additional manpower and takes only 15 minutes. SSi equipment is easily set up, often in less than 4 hours. ssilift.com

MWD shock absorber prototype for field testing

LORD Corp. has deployed the Generation 3.0 prototypes of the SoftShoe product line for field testing, a press release stated. The next-generation SoftShoe was developed to protect probe-style MWD tool strings from high-energy axial shock. This new generation is designed with a dual compression compliance element as compared to single compression in previous versions to provide additional longevity. The improved design ensures that whether a net compressive or a net tensile load is applied, the proprietary working elastomer section is put into compression. The design features dual compression operation, replaceable elastomeric package and natural frequency of 80 Hz. It also isolates instantaneous shocks at critical electronic frequencies (200-plus Hz) and attenuates high-energy transient shocks (duration ≤3 ms). lord.com

Systems ensure a permanent annular barrier

Archer Oiltools has released the new product family “Stronghold” for a series of perforating, washing and cementing systems, a press release stated. Stronghold encompasses modern perforation, wash and cement systems for a permanent annular barrier. The Stronghold systems consist of the Barricade, Defender and Rampart systems. The Barricade system perforates, washes and cements the annulus, creating a rock-to-rock barrier in one trip. The Defender barrier test system enables operators to perforate and test annular barrier. And Archer’s new Rampart cup-less system perforates, cleans and cements the annulus, also creating a rock-to-rock barrier in one trip. archerwell.com

Hydrogen sensor, gas detector designed to optimize performance

Tyco Gas & Flame Detection has released two new products: the Meridian hydrogen sensor and the Gasurveyor 700 (GS700), according to company press releases. The Meridian hydrogen sensor comes standard with two userselectable gas ranges, 4% by volume or 1% by volume, and is ideal for hydrogen detection in environments where catalytic bead sensor use is impractical or available power is limited. The sensors employ an electrochemical sensing element that needs recalibration just once every three months for optimum performance. In addition, the GS700 is a highly configurable infrared gas detector. Both lightweight and user-friendly, the GS700 includes a natural gas discrimination feature that allows the end-user to quickly determine the source of a gas leak. The GS700 also ensures compliance through intelligent data logging and GPS mapping, simplifying data collection and allowing better decision- making from tracking data reports. The durability and 3-lb portable functionality of the GS700 enables workers to maneuver the device in demanding environments and harsh conditions. TycoGFD.com

Drilling semisubmersibles for harsh areas

GustoMSC has released a new harsh-environment drilling semisubmersible series, the OCEAN-HE, a press release stated. The OCEAN850-HE and OCEAN1600-HE form the basis for the mid-water and deepwater harsh environment regions of operations, respectively. The semisubmersible hull shape is designed for low-motion characteristics and optimum station-keeping capabilities. The OCEAN1600-HE is the top of the range and the largest drilling semisubmersible design by GustoMSC. With a maximum displacement of about 70,000 tons, a large derrick, DP3 and a 16-point mooring system for station-keeping combined with a large deck area and large variable deck load, it aims at the highspec deepwater spectrum. It is designed to cope with North Atlantic environmental conditions. GustoMSC.com

Shaped charge lines designed for unconventional reservoirs

DynaEnergetics has released two families of shaped charges designed specifically to enhance well productivity and operational efficiency in unconventional reservoirs, according to a product announcement. The new HaloFrac shaped charge line incorporates DynaEnergetics’ latest technological advancements in liner materials and shaped charge geometry to improve hydraulic fracturing performance. HaloFrac delivers improved reservoir connection and increased total EUR as well as a reduction in well total cost of operations. Perforating with HaloFrac creates tunnel- tip fractures and ideal reservoir access for hydraulic fracturing fluid. This results in lower and more consistent breakdown pressures, uniform proppant placement, reduced screenouts, highly uniform frack clusters and higher well productivity ratios. The second line, FracTune, delivers uniform hole diameter in the well casing independent of shot phasing and gun positioning within the wellbore. Wells perforated with FracTune show low variation in flow and pressure across the perforations, uniform proppant placement, uniform frack clusters and reduced screenouts. dynaenergetics.com

Subsea cleaning system for pipeline care

Pipetech has released a new cleaning system for subsea infrastructure called the Deep Water Cleaning System (DWCS), a press release stated. The technology uses no chemicals, only water, to clean any subsea system to its original state. The high-pressure system carries away everything in its way—deposits of calcium, polycarbonates, copper, sulfur, coal, asphalt—removing even rockhard concrete deposits. The system is designed to reduce downtime and return the pipeline to its original state. The technology is not dependent on any auxiliary vessel to place the device on the seabed. The equipment is sunk through the moonpool of the rig and down to the subsea infrastructure, where it is placed over the wellhead. An ROV connects the water supply, and the unit is secured to the manifold with a pipe end connection tool. Then the cleaning operation begins. The equipment has a rotating hose drum that is used to feed the hose and nozzles into the pipe gates. This configuration means that the line is kept taut, preventing pigtails and cavitation from arising. The nozzles handle all kinds of bends with ease and can be navigated in many directions. pipetech.no

Water treatment unit removes toxic elements

Veolia has delivered an MPPE water treatment unit for the Ichthys LNG Project FPSO unit, a press release stated. The company’s MPPE unit will be used to treat the gas/ condensate-produced water stream on the Ichthys LNG Project’s FPSO unit. The MPPE unit will remove dissolved and dispersed toxic constituents, resulting in a zero harmful discharge to the environment. The ± 450-ton MPPE module unit, containing two parallel MPPE units, has been successfully loaded to Korea and placed on the FPSO unit. veoliawatertechnologies.com/en

Please submit your company's updates related to new technology products and services to Ariana Benavidez at abenavidez@hartenergy.com.

Recommended Reading

US Orders Most Companies to Wind Down Operations in Venezuela by May

2024-04-17 - The U.S. Office of Foreign Assets Control issued a new license related to Venezuela that gives companies until the end of May to wind down operations following a lack of progress on national elections.

EU Expected to Sue Germany Over Gas Tariff, Sources Say

2024-04-17 - The German tariff is a legacy of the European energy crisis that peaked in 2022 after Moscow slashed gas flows to Europe and an undersea explosion shut down the Nord Stream pipeline.

Pemex to Remain Fiscally Challenged for Mexico’s Next President

2024-04-16 - S&P Global Ratings said Pemex will remain a fiscal challenge for the country’s next president, adding that continued cautious macroeconomic management was key in its ratings on both Mexico and Pemex.

Yellen Expects Further Sanctions on Iran, Oil Exports Possible Target

2024-04-16 - U.S. Treasury Secretary Janet Yellen intends to hit Iran with new sanctions in coming days due to its unprecedented attack on Israel.