Tallgrass and Kanin Energy said construction on the waste heat to power projects—three in Ohio and one in Indiana—is expected to start early next year and reach first electron in early 2024. (Source: Shutterstock.com)

Tallgrass has teamed up with Kanin Energy, a green technology company, to convert waste heat to power (WHP) at four sites in the U.S., which will allow the midstream player to offset nearly 250,000 short tons of CO₂ equivalent annually while providing carbon-free power.

Construction on the projects—three in Ohio and one in Indiana—is expected to start early next year and reach first electron in early 2024. Together, the projects will provide 410,000 MWh of electricity annually, enough to decarbonize power to about 38,000 U.S. households, the developers said.

“We think the direction of the energy transition is pretty clear at this point, and so part of what we’ve done as a company is take a look at the assets that we operate to identify opportunities for on-footprint projects help reduce carbon emissions,” Justin Campbell, vice president of power and transmission for Tallgrass, told Hart Energy. “And these [WHP projects] floated to the top of that list. This is really about using a resource that’s wasted as heat and doing something productive with it that’s decarbonized.”

More companies are tapping the emissions-free power source as the world transitions to cleaner forms of energy and looks to live or operate more sustainably. Energy companies’ plans continue to unfold more than six years after world leaders signed the Paris Agreement in efforts to slow global warming.

The Technology

During the waste heat to power process, heat generated as a byproduct from industrial processes—heat that would’ve otherwise been released into the atmosphere—is captured and converted to electricity using Organic Rankine Cycle (ORC) technology.

“You need resources that can be dispatched at times when those others [wind and solar] aren’t producing, and that includes overnight, for example. These waste heat to power projects can provide that kind of power.”—Justin Campbell, Vice President, Power and Transmission, Tallgrass

As explained by Kanin Energy, waste heat from exhaust is diverted to pass over a heat exchanger that is connected to an ORC. The closed-loop system pipes an organic fluid through the heat exchanger to convert the fluid into a gas, which then passes through a turbine to create electricity.

“This is energy that doesn’t have any incremental emissions attached to it,” Kanin CEO and cofounder Janice Tran told Hart Energy. She noted that although WHP technology is not new, its use in North America is relatively new.

The total installed capacity for the four projects will be about 48 MW, with each ranging between 11 and 14 MW.

Tran described the waste heat energy as 24-7 carbon-free energy. The clean baseload power, with an emission profile comparable to hydro or solar plus storage, can help decarbonize electricity grids and provide a clean onsite energy source for companies at any time unlike intermittent solar or wind electricity.

“A lot of oil and gas companies are getting pressured from their stakeholders and their shareholders to pursue energy transition business lines and projects,” Tran said, adding decarbonization and energy transition are core to Tallgrass’ strategy.

“When we think about energy transition and what that actually looks like,” she said, “waste heat to power is an energy transition project that can be economically done today.”

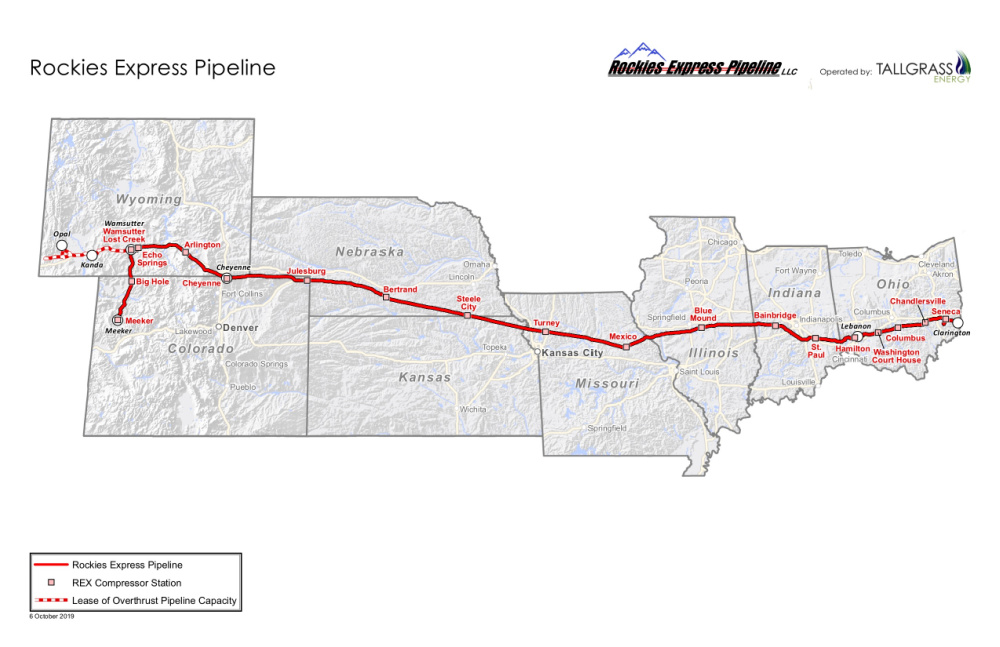

Waste heat for the project will come from the Rockies Express Pipeline, off the back of compressor stations, according to Tran. The pipeline is operated by Tallgrass, which owns 75%. Phillips 66 owns 25%.

The Rockies Express Pipeline is one of the largest natural gas pipelines in the U.S., spanning some 1,700 miles. The pipeline moves resources from basins in the Rocky Mountain and Appalachian regions and has direct access to power plants and local distribution companies.

More to Come?

Electricity generated from the four projects will be sold back to the grid, creating another revenue stream for Tallgrass, Campbell said. The company is exploring opportunities for offtakers.

“You need resources that can be dispatched at times when those others [wind and solar] aren’t producing, and that includes overnight, for example. These waste heat to power projects can provide that kind of power,” Campbell said. “We’re looking to sell that power to third parties on the PJM transmission system.”

“Waste heat to power is an energy transition project that can be economically done today.”—Janice Tran, CEO, Kanin Energy

The PJM interconnection coordinates electricity throughout 13 northeastern states and the District of Columbia.

Neither Tran nor Campbell disclosed how much the projects will cost. Tallgrass is providing capital, Campbell said.

“I can say that compared to other forms of 24-7 carbon-free energy like solar plus storage or hydrogen electricity, we’re the most economical form of it and it also works today,” Tran said.

Questions surround other carbon-free energy technologies, including commercial availability, “but ours is commercially available today. … Waste heat to power is something that can be done without any technology risk, and it can also help them monetize a waste product,” she added.

Tallgrass is also considering undertaking similar projects at other sites.

“Broadly, we’re looking not just at waste heat, but we're looking at other opportunities like in places where you have changes in pressure on the gas system to generate power [and] decarbonize power,” Campbell said. “We are also looking for opportunities off footprint in waste heat to power. So more to come on that, but it’s certainly something that we’re excited about as a business.”

The WHP projects are one of several decarbonization projects Tallgrass has underway. Other include its Trailblazer carbon capture and sequestration project in Nebraska, where it plans to sequester CO₂ emissions from ADM’s corn processing complex. Its Trailblazer natural gas pipeline will be converted into a 400-mile regional CO₂ transportation system capable of transporting more than 10 million tons of CO₂ annually for permanent sequestration.

Tallgrass is also working to convert a coal-fired power plant in New Mexico to run on hydrogen.

“It’s pretty exciting stuff,” Campbell said. “We’re very much on the lookout for those kinds of opportunities and hard at work on those kinds of things.”

Recommended Reading

Ithaca Energy to Buy Eni's UK Assets in $938MM North Sea Deal

2024-04-23 - Eni, one of Italy's biggest energy companies, will transfer its U.K. business in exchange for 38.5% of Ithaca's share capital, while the existing Ithaca Energy shareholders will own the remaining 61.5% of the combined group.

EIG’s MidOcean Closes Purchase of 20% Stake in Peru LNG

2024-04-23 - MidOcean Energy’s deal for SK Earthon’s Peru LNG follows a March deal to purchase Tokyo Gas’ LNG interests in Australia.

TotalEnergies to Acquire Remaining 50% of SapuraOMV

2024-04-22 - TotalEnergies is acquiring the remaining 50% interest of upstream gas operator SapuraOMV, bringing the French company's tab to more than $1.4 billion.

TotalEnergies Cements Oman Partnership with Marsa LNG Project

2024-04-22 - Marsa LNG is expected to start production by first quarter 2028 with TotalEnergies holding 80% interest in the project and Oman National Oil Co. holding 20%.

Is Double Eagle IV the Most Coveted PE-backed Permian E&P Left?

2024-04-22 - Double Eagle IV is quietly adding leases and drilling new oil wells in core parts of the Midland Basin. After a historic run of corporate consolidation, is it the most attractive private equity-backed E&P still standing in the Permian Basin?