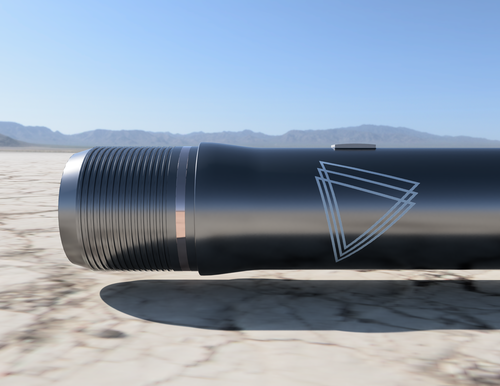

The more that progressive oil and gas companies can harness this kind of advantageous technology, the more stable the industry will become, Berry says. (Source: Shutterstock.com)

If you were to map mankind’s most recent technological advances on a graph, you’d see a steep rise in innovation around the time of the Industrial Revolution, with the advent of chemical manufacturing, alternative power generation and large-scale mechanization. In the last century, however—and especially into the Anthropocene epoch—innovation of this kind has been close to exponential, with no signs of slowing.

The oil industry has had a turbulent time of late, especially seeing the effects of the pandemic, but the team at the U.K. oil company, TriStone Holdings, are hopeful about new technologies which are continually helping to shape its future in truly exciting ways, said director, Henry Berry. Below is some of the industry tech Berry considers most noteworthy at the moment.

Technologies once restricted to the confines of the imagination are now becoming reality. As with so many other sectors at the moment, the oil industry remains in a relatively volatile position thanks to COVID-19. New technologies like those mentioned by Berry below, however, are most definitely part of the solution in getting back on track.

The more that progressive oil and gas companies can harness this kind of advantageous technology, the more stable the industry will become, Berry said.

Smart Pipelines

Nowadays, ‘smart’ seems to be the new industrial buzzword. Whether it be smart highways or smartphones, any opportunity for such digital streamlining should be welcomed - especially from an investor’s standpoint. Pipelines are the latest infrastructural component set to receive a digital transformation over the coming years. In fact, Tri-D Dynamics (a Silicon Valley tech firm) signed an agreement with Japanese steel firm Marubeni-Itochu Steel Inc. (MISI) in December to develop smart pipelines. They have the capability to provide accurate digital tracking within the pipes; helpful in everything from infrastructural improvements to environmental monitoring. Oil investment companies are constantly looking at the market to see where areas can be optimized. To see tech innovators, like Tri-D Dynamics, implement solutions at the leading edge of technology shows just how much the industry continues to modernize.

Wearable Exoskeletons

The Guardian XO full-body exoskeleton by Salt Lake City-based robotics firm, Sarcos, is set to launch commercially this year. Though it looks futuristic, the problems it’s set to solve are very much present-day. With potential applications including everything from warehouse work to construction, the oil and gas sector falls very much in the wheelhouse of the XO’s abilities.

Requiring only minimal training, and easily entered and exited, it can easily lift 200 pounds’ worth of weight without breaking a sweat. In what’s still a labor-heavy industry—in spite of increasing automation—suits like Sarcos’ might be commonplace on rigs around the globe in the not too distant future.

Their newest product, the Guardian XT, is a teleoperated robot with a wearable VR exoskeleton which can carry out the most intricate and dexterous of human tasks, even at height, whilst allowing the operator to maintain a safe distance. This is the future of risk mitigation for dangerous tasks.

Digital Twin Technology

The extended reality (XR) industry is still relatively new, however there are applications for VR and AR in almost every vertical and horizontal market, oil is no exception. Digital twins are a virtual representation of a physical process, and can be used by scientists and engineers to run simulations prior to actual physical devices being built. This makes them highly cost-effective and tease out problems before they’re actual, real-life problems. This technology is already seeing adoption from some of the globe’s largest players, including Equinor ASA and BP Plc. From offshore platforms to process streamlining; risk assessment and H&S to production refinement, it’s no surprise that many companies are taking interest in technology like this. It promises to iron out potentially troublesome kinks in processes—smoother processes, in turn, contribute to smoother financials.

About the Author:

Henry Berry is director at TriStone Holdings Ltd., an energy company based in the U.K. with a primary focus in the U.S. TriStone finds, develops and produces essential sources of energy and their portfolio includes high-quality conventional oil and natural gas assets in the top U.S. onshore plays.The company is currently raising capital to acquire and expand its energy base, specifically in the oil and gas sector.

Recommended Reading

Excelerate Energy, Qatar Sign 15-year LNG Agreement

2024-01-29 - Excelerate agreed to purchase up to 1 million tonnes per anumm of LNG in Bangladesh from QatarEnergy.

UK’s Union Jack Oil to Expand into the Permian

2024-01-29 - In addition to its three mineral royalty acquisitions in the Permian, Union Jack Oil is also looking to expand into Oklahoma via joint ventures with Reach Oil & Gas Inc.

Permian Resources Continues Buying Spree in New Mexico

2024-01-30 - Permian Resources acquired two properties in New Mexico for approximately $175 million.

Eni, Vår Energi Wrap Up Acquisition of Neptune Energy Assets

2024-01-31 - Neptune retains its German operations, Vår takes over the Norwegian portfolio and Eni scoops up the rest of the assets under the $4.9 billion deal.

NOG Closes Utica Shale, Delaware Basin Acquisitions

2024-02-05 - Northern Oil and Gas’ Utica deal marks the entry of the non-op E&P in the shale play while it’s Delaware Basin acquisition extends its footprint in the Permian.