It takes a significant amount of energy to transport the ever-growing supply of natural gas in the U.S from where it is produced to where it is consumed. At each compression station, there are multiple opportunities to convert the existing waste heat streams to additional electricity for the site and potentially more horsepower for increased compression and through-put. This can be achieved with no added fuel or emissions, using technology that is proved and established worldwide.

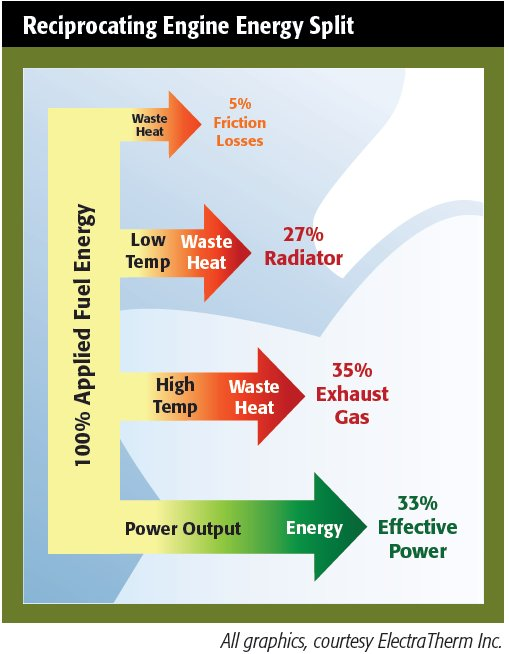

Organic Rankine Cycle (ORC) technology has been around for decades, but only recently established itself as a proven source of power generation from low-temperature “waste” heat streams. Such heat streams are commonly found on reciprocating engines, where an ORC generator can increase engine performance and decrease fuel consumption by converting the engine’s jacket water and/or exhaust into additional electricity for the site. The typical engine runs at about 35% efficiency, resulting in considerable waste heat between the jacket water and the exhaust.

Engine applications are common and include: prime power production in remote areas, island and developing nations, biogas gensets such as landfill and wastewater treatment plants and renewable biofuels. The thousands of natural gas compression engines across the globe also provide a great opportunity to convert waste heat to power.

Ready renewable

Waste heat in its many forms is an abundant renewable energy resource that many don’t realize—a renewable you already have.

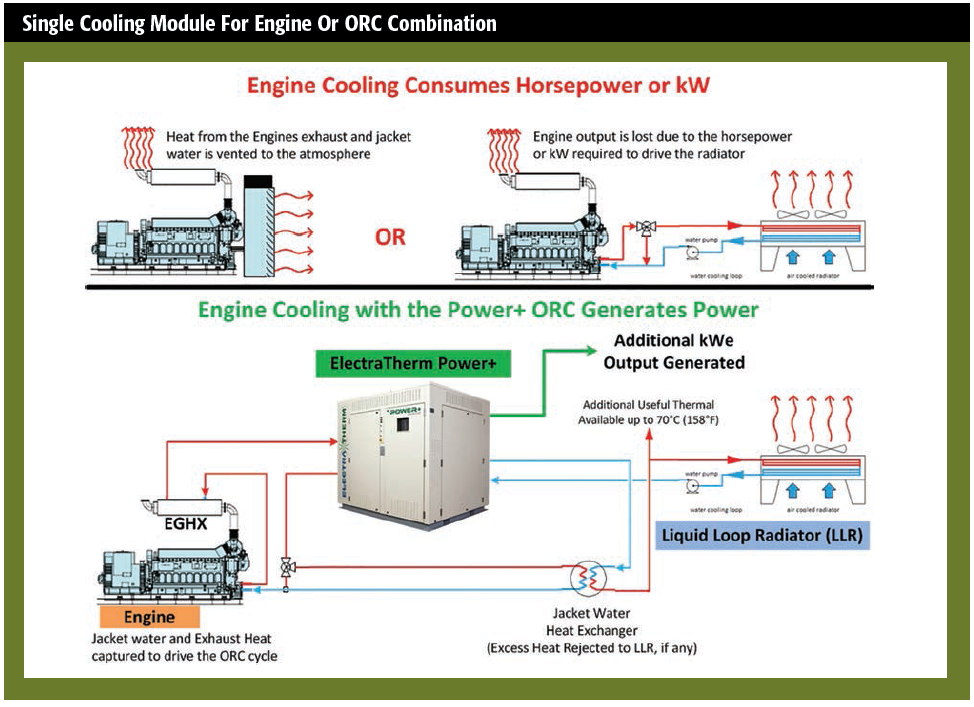

ORC generators are cooling devices. They can act as the engine’s radiator, essentially working as a “radiator with a payback,” meaning a radiator that generates electricity and saves fuel. For all engine applications, there is an associated cost of cooling the engine, either in horsepower provided by the engine or in electricity purchased from the grid for radiator fans. By adding an ORC to an engine installation, the parasitic load of cooling the engine can be greatly reduced or even eliminated. The ORC turns the cost of cooling into the payback of cooling.

The Organic Rankine Cycle has been around for decades, but only recently has been utilized as an economical means of low-temperature power generation. The ORC works like a refrigerator running in reverse, where heat flow across a difference in temperature generates power. The ORC replaces water and steam associated with typical Rankine cycles with alternative low-boiling-point fluids, to successfully use heat that is typically at temperatures far too low to drive a steam engine.

ElectraTherm Inc.’s power block, the twin-screw expander, represents a dramatic change from radial or axial turbine technologies, providing a more cost-effective, robust machine to generate fuel-free and emission-free electricity from a variety of heat sources. This distinction enables ElectraTherm’s ORC technology to work effectively and economically in low temperature (less that 250 F) waste heat markets. The twin screw expander offers distinct advantages for low-temperature, small-scale ORCs—such as simple and compact design, low-speed operation, the ability to handle heat input variations and dual-phase flow of the working fluid, significant part-load capability, no gear box or oil pump. These are particularly advantageous in low-temperature, waste-heat streams, such as reciprocating engine jacket water.

The graphic at right shows that a significant portion of the waste heat on a reciprocating engine is at low temperatures. This can vary greatly depending on engine throttle position.

Waste heat solutions

This level of heat rejection is common to diesel, natural gas or biomass-powered reciprocating engines. Exhaust stack gases from virtually all combustion processes (ovens, kilns, furnaces, incinerators, thermal oxidizers and boilers) contain a large share of the original energy of the fuel consumed. When this heat is recovered and converted into electricity, the overall plant efficiency increases.

Historically, low-grade waste heat has been ignored for several reasons:

1. Low-temperature waste heat can’t drive conventional heat engines such as water-based Rankine cycle systems (steam-turbine power plants). A lower-temperature method of converting this heat into electricity is needed. Solution: ORC technology can capture the lower temperatures previously unattainable and utilizing a robust, low-RPM power block such as the twin screw expander, drives attractive economics.

2. Though the total amount of heat can be very large, it is geographically diverse. There’s insufficient heat available at individual process sites to utilize the most commonly available heat-engine solutions, typically rated in megawatts. The distributed nature and variation of available waste heat sources demand smaller, modular and distributed generation technology. Solution: Small-scale power generators that are easily transportable and installed and have low maintenance with a small footprint can now access waste heat sources previously overlooked.

3. Industries produce heat as a byproduct of their primary enterprise, so they generally don’t consider waste heat to power as an integral part of their operations. Often, sites do not have the personnel with the skills or desire to recognize a power generation opportunity, design and install heat capture and ORC hardware, or operate and maintain power station-type equipment. A viable solution must be easy to install, operate and maintain. Solution: Small-scale ORC technology is easy to install, low maintenance and can be remotely controlled and operated. Anyone with HVAC or engine experience can manage routine maintenance.

4. Finally, low relative energy costs, as well as the historically intangible nature of the environmental benefits associated with reduced emissions, made the payback period of small waste heat-to-power equipment too long. Solution: Rising costs of energy—including the environmental costs of fossil fuel combustion—coupled with enabling new technology, have reduced the return on investment for waste heat-to-electricity conversion equipment.

Cooling device

There are multiple benefits to integrating an ORC heat-to-power generator with an engine genset to make it an efficient engine cooling device. The above graphic for the engine/ORC schematic shows the single cooling device configuration, where the engine’s radiator—and its capital cost—is eliminated.

The first benefit is clear: There is additional electrical output from the conversion of the waste heat to electricity with no additional fuel consumption or emissions. Second and less obvious is the reduction or elimination of the parasitic load from the engine cooling fans. The Power+ generator acts as the radiator, allowing the engine-driven radiator fans to be disconnected (or never purchased). Without the parasitic load of the radiator, more work can be performed by the engine to generate additional electricity. The Power+ generator electricity output, combined with the engine’s reduced parasitic load, account for a gain of up to 10% in fuel efficiency, depending on engine size, configuration and the ambient temperature of the site.

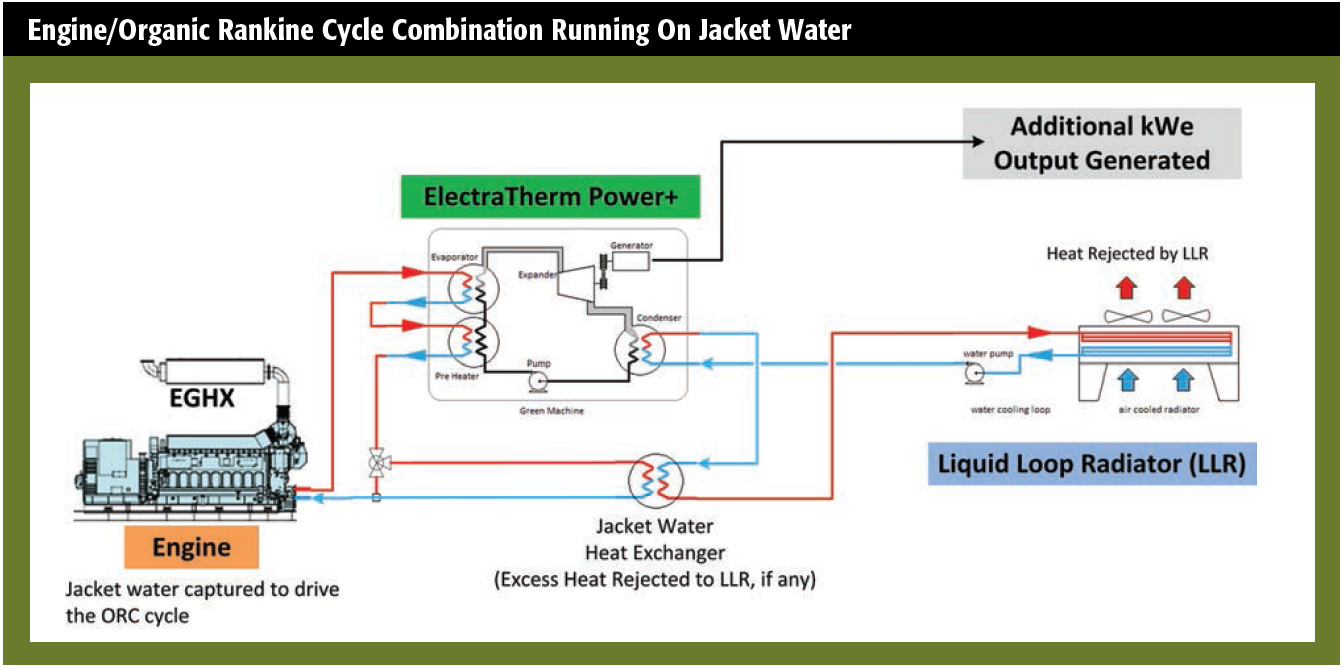

Depending on the engine size, the ORC cycle can be further optimized to make the best use of the available heat. If the exhaust is not available due to emissions-control hardware, or if it is already captured for another use, then the ORC can be tailored to run just on the jacket water. The accompanying photo illustrates this configuration.

Another option, when exhaust heat is available, is to split out the heat streams coming into the ORC cycle. The lower temperature jacket water provides the preheat duty of the cycle, and the higher temperature exhaust heat provides the evaporation duty. The graphic at the top of the next page shows this approach. This configuration has the advantage of maximizing the temperature going into the evaporator which helps to drive a large temperature difference between the hot and cold sides of the cycle. The higher the temperature difference across the cycle, the greater the power output from the ORC. This is especially useful in areas of high ambient conditions, where the cold side of the cycle is elevated.

Additional compression

ElectraTherm’s experience to date with engine integration has included single and multiple engines utilizing jacket water heat alone as well as jacket water combined with exhaust heat. ElectraTherm’s ORC has been integrated with engine models from Jenbacher, Deutz and MWM in Europe and CAT and Waukesha engines in North America.

As ORC technology continues to grow in varying applications and geographies, new opportunities will bring value to the marketplace. The large number of stationary engines associated with natural gas compression provide ample waste heat and are well suited for ORC technology.

At a compressor station, a portion of the gas input is diverted to an engine, responsible for the mechanical work to compress the gas, as well as the work to cool the engine via a power takeoff (PTO). Work is also used to cool gas between the compression stages with a PTO. Cooling is a major task at compressor stations, where significant mechanical work is required to cool three components: 1) engine jacket water, 2) intercooler and 3) multiple steps of natural gas compression. The end result is less compression station throughput and more engine work.

By incorporating an ORC into the mix, shaft-driven fans driving the engine radiators can be removed, freeing up engine horsepower for increased compression. The ORC creates electricity for other site loads by consuming engine jacket water and/or exhaust heat. The cooling duties for the natural gas compression engine are reduced to just one—natural gas cooling after compression. Plus, the ORC-generated electricity has the potential to be converted to more compression via an additional electric compressor. More compression means more gas throughput, which equates to increased revenue flows.

Converting the existing waste heat streams to more compression without increased emissions can be of particular interest in emissions-capped (non-attainment) areas where another engine cannot be easily added.

An ORC is a unique approach for increasing plant throughput without additional emissions, thereby keeping the station under existing permitted levels.

Recommended Reading

How Diversified Already Surpassed its 2030 Emissions Goals

2024-04-12 - Through Diversified Energy’s “aggressive” voluntary leak detection and repair program, the company has already hit its 2030 emission goal and is en route to 2040 targets, the company says.

BKV CEO Chris Kalnin says ‘Forgotten’ Barnett Ripe for Refracs

2024-04-02 - The Barnett Shale is “ripe for fracs” and offers opportunities to boost natural gas production to historic levels, BKV Corp. CEO and Founder Chris Kalnin said at the DUG GAS+ Conference and Expo.