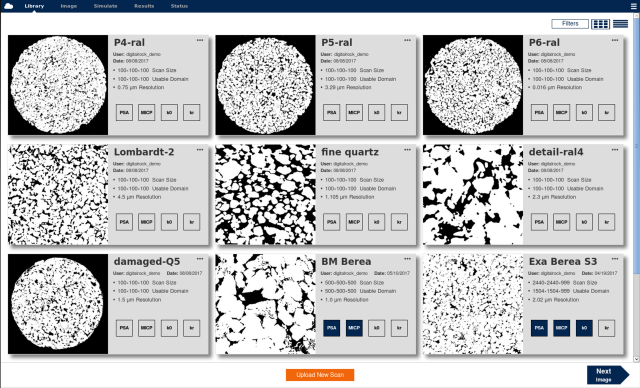

DigitalROCK allows users to isolate more rock types to identify lithotypes. (Source: Exa)

Those who attended the Abu Dhabi International Petroleum Exhibition and Conference (ADIPEC) in 2017 might have had a chance to hear Exa and BP present a paper on a multiyear data study showing results of the industry’s first relative permeability software solution. The DigitalROCK software is intended to get petrophysicists out of the laboratory by enabling them to evaluate rock formations and assess relative permeability to accurately assess reservoir output. E&P recently talked to David M. Freed, vice president of Exa’s Oil & Gas Division, about the potential for this technology.

E&P: Please share a brief background about the company.

Freed: Exa was founded in 1991 and for the past 20 years has been in the business of providing an accurate computational fluid dynamics solver for automotive aerodynamics and related applications. It’s a revolutionary way to do fluid flow simulation based on this technology called the Lattice-Boltzmann [LBM] method.

Exa was the first company to build a business from commercializing LBM. So having built up market leadership and a core business in fluid flow related to cars, trains, airplanes, heavy equipment and related applications, at some point we recognized that our technology could be ported over to the oil industry.

We always knew that we had a unique technical advantage for multiphase flow, but we didn’t use it until we started working on this DigitalROCK application. Over the last five years we leveraged our technology foundation to develop the DigitalROCK capability.

E&P: Can you explain how LBM works?

Freed: Let me first say a few words about how fluid dynamics is usually done on a computer. Historically, people have taken what they call the fluid flow equations and tried to solve those directly on the computer, and that’s a fine thing to do, but it does run into limitations. There are times when the computer has to deal with a very large numerical simulation, and it becomes harder to scale.

With the LBM approach you’re taking the point of view of the particles. But you don’t follow each individual particle. You follow what we call groups of particles or particle distribution. You can think of it as a bottom-up approach. By taking this approach and being very precise in how you track the movement and interaction of particles, you can perform complex fluid flow situations in a more natural way that lends itself well to dealing with very large or very complex flow systems.

E&P: Exa recently co-wrote an ADIPEC paper with BP. Can you go into a few details about that company’s interest and why it chose to undertake this project?

Freed: BP had been working on DigitalROCK for a long time and had gone quite far with it. Their scientists had developed world-class imaging capabilities. By imaging, I mean the ability to use a microcomputer tomography scanner to create a 3-D tomographic image from which you can then discern the actual pore space of a rock sample and use that pore space geometry as the basis of various rock property analyses. So the company was already a leader in the imaging and image processing, and it can do several kinds of analyses to determine important geophysical and petrophysical properties of the rocks.

But what BP really wanted to do was to be able to do multiphase flows to calculate the relative permeabilities, for example, water and oil or oil and gas flowing together. In real reservoir rock you always have a mixture of fluids.

At some point BP ran into us, and we were already pretty far along in developing a multiphase flow simulation capability. We realized that by partnering we would be able to take it all the way.

At this point Exa didn’t have much of an oil and gas background. It was our first entry into the industry, so we needed a partner that would provide that domain expertise and have physical test data to compare the simulation results to. BP needed a partner that had the fundamental technology to do the multiphase flow simulation. By joining forces over the course of a few years, we were able to take the solution all the way through to being tested and validated against high-quality physical lab test data.

E&P: What kind of a learning experience was that for you?

Freed: It was pretty epic. I think it was one of the most amazing journeys of my career to work with the really brilliant and visionary people at BP, [who are] technically very capable people, and to work together as a team, solve this problem and work through all of the challenges that come up when you’re trying to compare computer simulation predictions to real-world physical lab tests. It was an incredible experience to bring those different domains of expertise together to solve this problem.

We were working with a dedicated interdisciplinary team, a DigitalROCK group. It was composed of people with a reservoir engineering background but also with imaging expertise and expertise in relative permeability and multiphase flow in reservoir rocks.

E&P: Why do you think your solution is better than some of the others that are out there?

Freed: We didn’t invent the idea of DigitalROCK. It was already around, and there were already researchers and companies working in this space. And I think a lot of them got pretty far. I think that you can already get some value out of the images, see things that help you understand your rocks. People also got pretty far with being able to look at porosity and do single-phase flow, which gives you the absolute permeability.

What the industry really needs, though, is the multiphase flow [and] the relative permeabilities. And I think that’s where the other companies and researchers in this field fell short. There really wasn’t an accepted or credible multiphase relative permeability prediction capability out there before. We’re really the first to crack that nut in a robust and credible way.

E&P: There’s always the scaling issue if you’re taking something at a microscopic level and trying to expand it out to reservoir level.

Freed: With DigitalROCK, with the digital version of the lab tests, you can do many more samples because it’s so much faster. And not only that, you can really isolate each rock type. You do a little geology ahead of time to identify the rock types and lithotypes. And then you want to get some reasonable number of samples for each of those lithotypes. Then you’re able to characterize each of the lithotypes independently and feed that set of information into your reservoir simulator.

I think that the big take-home benefit, if I had to name just one, is the much faster analysis time for the digital instead of the physical lab tests. Because of that faster time there are many things you can do, [such as] what-if studies and really understanding sensitivities to different flow and rock system parameters. I think those are the key benefits of the technology, and Exa is committed to help the industry leverage this technology to really be a game changer in terms of better field characterization and production optimization.

E&P: It seems like your approach has more of an EOR focus.

Freed: Well, I think EOR is a good example of a use case where you really have to be talking about multiphase relative permeabilities or multiphase capillary pressure prediction. That’s what makes all the difference. If you’re going to run a waterflood or add a surfactant, is that going to change your relative permeability? Is it going to change your endpoint, which is the residual oil? That’s the whole name of the game. Porosity and single-phase permeability can already help you with your reservoir characterization. But then the multiphase capabilities take it to the next level around whether an EOR technique is going to be feasible and economic on a particular set of rock types.

Recommended Reading

Brett: Oil M&A Outlook is Strong, Even With Bifurcation in Valuations

2024-04-18 - Valuations across major basins are experiencing a very divergent bifurcation as value rushes back toward high-quality undeveloped properties.

Marketed: BKV Chelsea 214 Well Package in Marcellus Shale

2024-04-18 - BKV Chelsea has retained EnergyNet for the sale of a 214 non-operated well package in Bradford, Lycoming, Sullivan, Susquehanna, Tioga and Wyoming counties, Pennsylvania.

Triangle Energy, JV Set to Drill in North Perth Basin

2024-04-18 - The Booth-1 prospect is planned to be the first well in the joint venture’s —Triangle Energy, Strike Energy and New Zealand Oil and Gas — upcoming drilling campaign.

PGS, TGS Merger Clears Norwegian Authorities, UK Still Reviewing

2024-04-17 - Energy data companies PGS and TGS said their merger has received approval by Norwegian authorities and remains under review by the U.K. Competition Market Authority.

Energy Systems Group, PacificWest Solutions to Merge

2024-04-17 - Energy Systems Group and PacificWest Solutions are expanding their infrastructure and energy services offerings with the merger of the two companies.