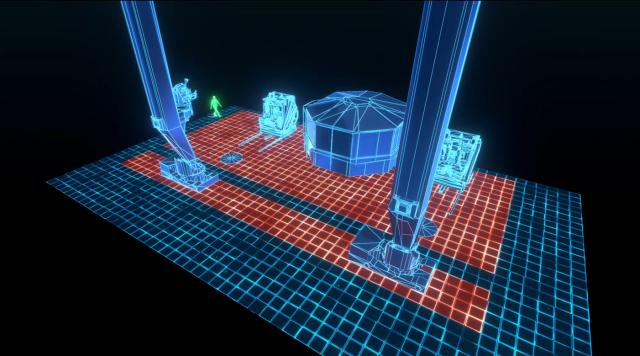

VisionIQ, with 3D view, tracking personnel and showing configurable red zones. (Source: Seadrill Ltd./The Marsden Group)

HOUSTON—Seadrill has launched a new technology aimed at safety management on drilling rigs in one of offshore’s most dangerous areas.

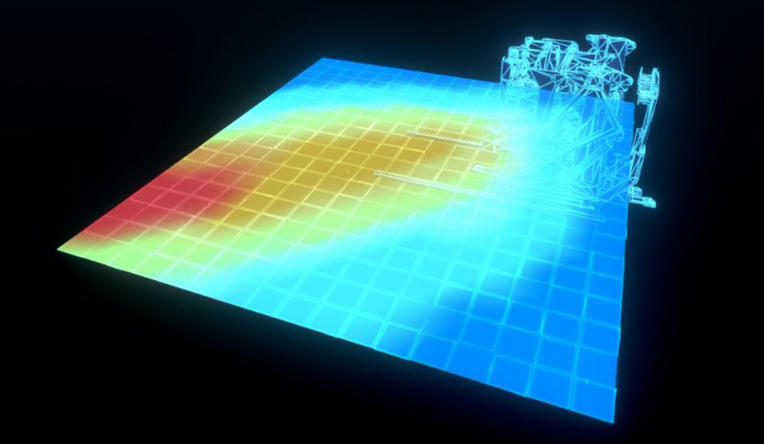

Developed by Marsden Group, Vision IQ is an artificial intelligence (AI)-enabled safety technology aimed at monitoring risks within a rig’s Red Zone. The high-risk area is the portion of the rig floor where heavy drilling equipment moves, making it a vulnerable spot for injuries. Thus, Seadrill tapped Marsden to mitigate the danger and ensure a safe environment for the workers.

“You hear about this digital transformation and everyone’s focused on technology first. We’re focused on humans first,” said Jennifer Hohman, Seadrill’s chief information officer and vice president, at Marsden Group’s R&D facility tour on Sept. 13.

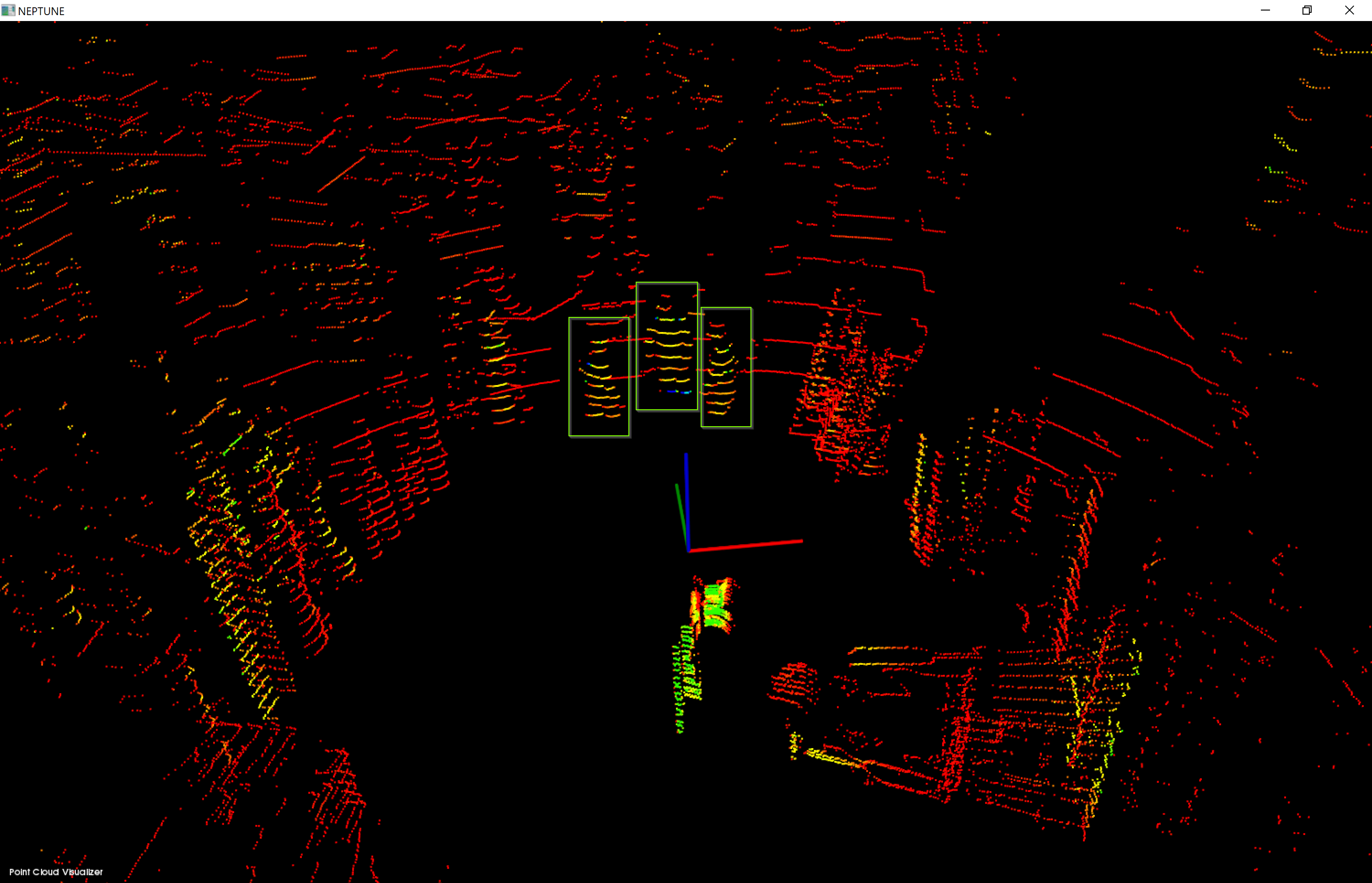

The partnership, she said, focused on leveraging technology that informs both people on the platform and those watching the platform. To optimize rig operations, the safety system utilizes AI, laser imaging, detection and ranging (LiDAR), and high-power computing technology.

In perspective, the concept builds on driver-assistance technology where the radars provide alerts to driver’s to reduce human error and promote safety.

Being laser-based—and also equipped with three high-resolution cameras—each Vision IQ unit can conduct 3-D scanning to create a dynamically monitored environment of the Red Zone in real-time.

The two features work in unison to identify crew members and provide an advanced alert for potential danger both in the Red Zone and in the rig’s dog house. But, Marsden and Seadrill team also wanted to exercise safety by protecting the worker’s privacy from the technology.

“We’ve been very conscious of people’s individual identity and not capturing tons of sensitive personal data about [them],” said Andy Pratt, The Marsden Group’s president. “We don’t track the names or the individual biometrics of people. This is about people being safe as a whole, not individualizing.”

Pratt said Marsden intentionally left out more detail-oriented technology like facial recognition that would track people to avoid Vision IQ becoming a “blaming toolset.”

“We’re not trying to identify you, we’re trying to identify the role you do and how you do that and that’s the data [workers] contribute to the system,” he said.

Incoming technology into the industry often raises concerns that it will replace humans. But, Pratt said, in developing Vision IQ, his team worked closely with drill floor workers which “made all the difference”.

“It’s not about replacing the driller, it’s about giving the driller new jobs where he can focus on how to optimize and make things better,” he said.

Seadrill plans to deploy Vision IQ on a rig located in the Gulf of Mexico and install the tech on 12 more rigs globally following high interest, according to Seadrill’s director of solutions John Alvarado. Marsden is also working on a downsized camera-only module of the tech for smaller, less critical corridors.

“We’re putting our resources, time and money where our mouth is,” Hohman said. “We are very serious about the culture of our company and making sure everybody on our platform is safe and everybody in any part of our operations goes home to their family, friends and children.”

Recommended Reading

SLB’s ChampionX Acquisition Key to Production Recovery Market

2024-04-21 - During a quarterly earnings call, SLB CEO Olivier Le Peuch highlighted the production recovery market as a key part of the company’s growth strategy.

PHX Minerals’ Borrowing Base Reaffirmed

2024-04-19 - PHX Minerals said the company’s credit facility was extended through Sept. 1, 2028.

Matador Resources Announces Quarterly Cash Dividend

2024-04-18 - Matador Resources’ dividend is payable on June 7 to shareholders of record by May 17.

EQT Declares Quarterly Dividend

2024-04-18 - EQT Corp.’s dividend is payable June 1 to shareholders of record by May 8.

Magnolia Oil & Gas Hikes Quarterly Cash Dividend by 13%

2024-02-05 - Magnolia’s dividend will rise 13% to $0.13 per share, the company said.