As oil and gas prices remain lower for longer, producers seek opportunities for continuous improvement. Great strides have been made since 2015 in reducing breakeven prices. Recent reports have indicated that breakeven prices in major North American plays now range from $30/bbl to $50/bbl, depending on the play and operator.

The Packers Plus line of cemented completions aims to build on this success. Both QuickFRAC (limited entry) and Diffusor (single-point entry) cemented systems are designed to address common issues such as running the system to bottom, accessing the toe section of long laterals and achieving uniform stimulation.

System installation

A critical part of any installation is getting the system to the planned depth. During installation it can be helpful at times to rotate the liner. Rotation breaks static friction and allows the system to move through tight areas. However, not all liners are designed for rotation. The Packers Plus Premium Liner Hanger has a high torque rating that allows operators to rotate, push and pull on the liner hanger without accidentally releasing the running tool.

The Packers Plus Premium Liner Hanger has a high torque rating that allows operators to rotate, push and pull on the liner hanger without accidentally releasing the running tool.

A liner hanger must also be robust enough to handle the weight required to push on the tool string without unintentionally presetting slips or packers. The Premium Liner Hanger can hang loads up to 350,000 lb, with a packer designed for maximum contact area rated to 10,000 psi of differential pressure.

The running tool used to install and cement the liner hanger must be able to release reliably. This tool is designed with both primary and secondary releases to lower operational risk.

Extended-lateral completions

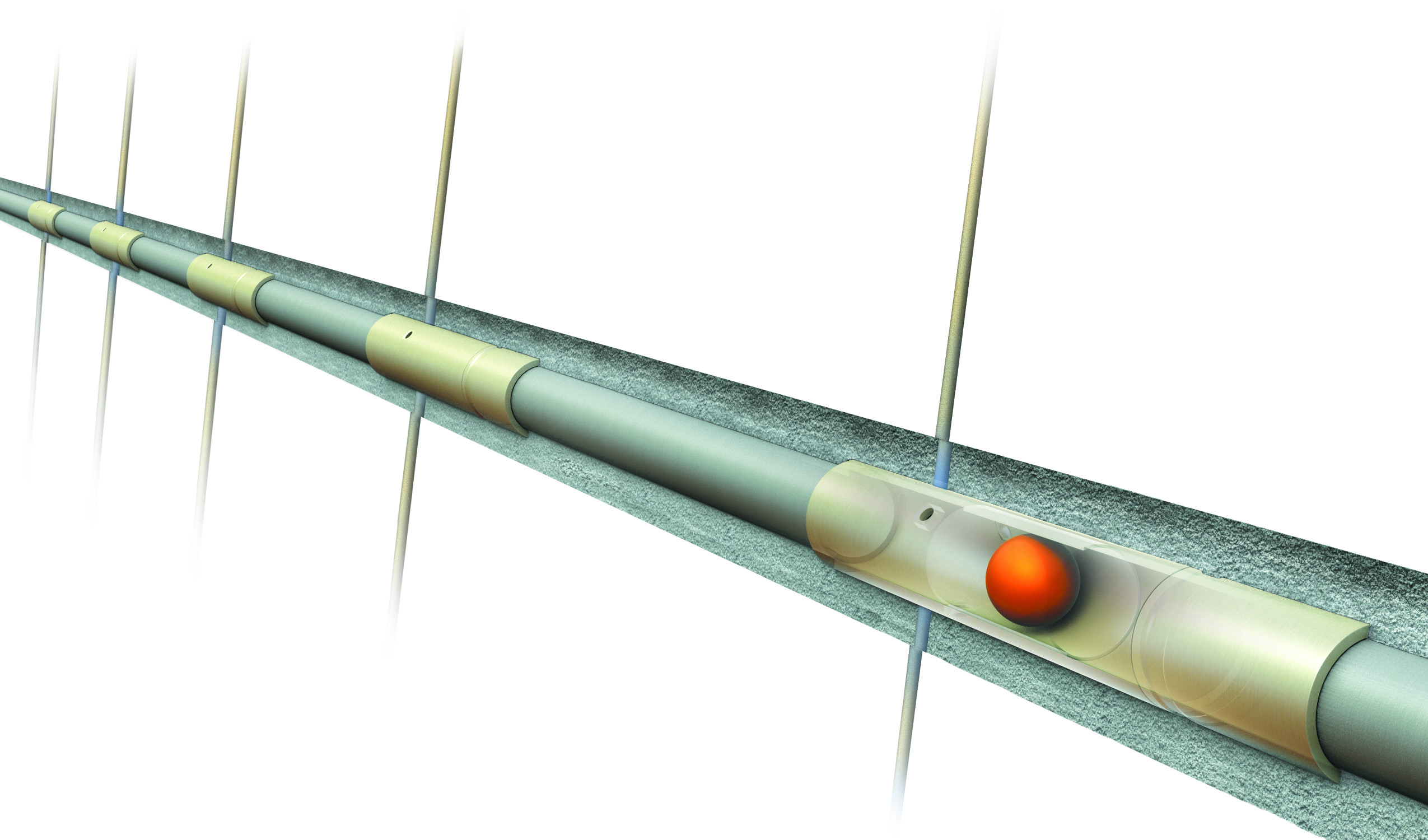

For extended-lateral wells, ball-activated systems provide a major advantage in accessing the toe of the well to initiate treatment without having to pump wireline or push coiled tubing. Cemented ball-activated technologies, including Diffusor for single-point entry and Quick- FRAC for limited entry, enable both cost and time efficiencies for the toe stimulation of an extended lateral.

Eliminating trips in and out of the well at each stage is particularly significant in extended laterals, where plug conveyance and millout become riskier. It becomes increasingly difficult to put weight on the bit as the millout progresses toward the toe, increasing operational risk.

Stimulation treatment distribution

A common problem with limitedentry stimulation is that perforations near the heel of a stage are typically quickly eroded by proppant flow. This can result in uneven distribution of fluid between perforation clusters, which results in uneven stimulation of the stage. Furthermore, logging and tracer data have shown that clusters do not contribute equally to production.

Limited-entry treatment using the QuickFRAC system ball-activated sleeves resolves this issue with erosion- resistant tungsten carbide-reinforced ports. These entry points are able to withstand high pressures and flow rates, facilitating consistent fluid distribution throughout the clusters (Figure 1).

When high breakdown pressures require high fluid rates, single-point entry completion systems such as Diffusor are more effective at stimulating some formations compared to limited entry.

A study modeling the completion and reservoir data in the Wolfcamp Shale estimates a 12% higher EUR over 30 years from wells completed with singleentry stimulation compared to traditional limited entry using plug and perf.

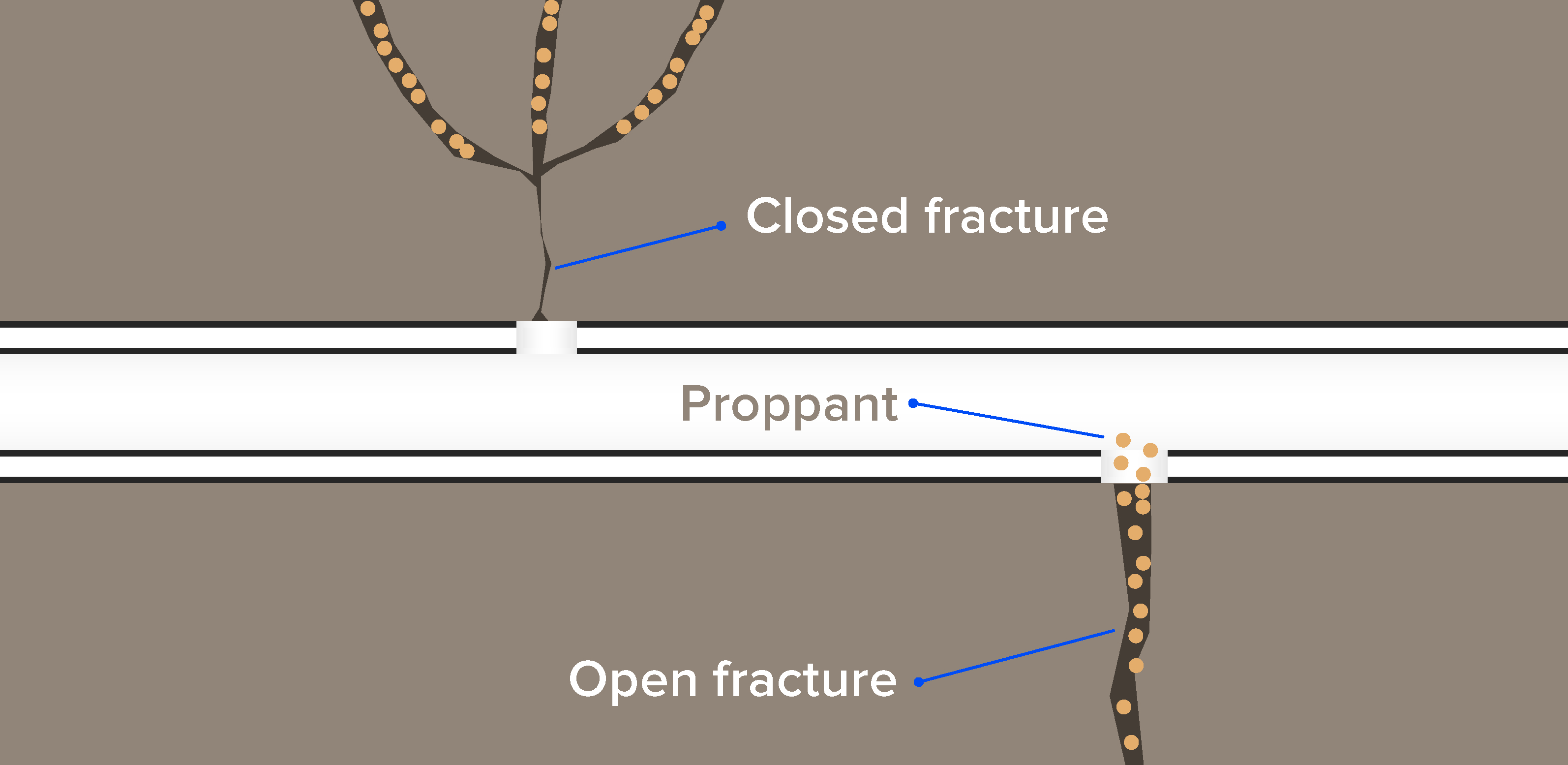

Finally, ball-activated systems can sidestep the potential for overdisplacing proppant. Excess fluid can push the proppant near the wellbore deeper into fractures, causing the near-wellbore fractures to close. This leads to poor near-wellbore conductivity and lower production.

In ball-activated systems, overdisplacement can be controlled or avoided because the ball can be pumped within the flush volume of the previous stage’s treatment (Figure 2).

High-efficiency cemented completions

The debate about the merits of differing completion styles is ongoing. Regardless of promised advantages, low oil and gas prices might prevent operators from venturing away from familiar methods. To stay competitive, flat-rate or per-stage service fees have become more common in the current market. This reduces the premium offered by the efficiency of ball-activated systems since ball-activated completions are typically done at least three times faster. As a case in point, during a QuickFRAC toe stimulation in Oklahoma, the transition time between the ball-activated stages was about 15 minutes.

Price wars aside, time efficiency is still king. While revenue can be recovered, time cannot. Packers Plus’ cemented technology addresses many of the inefficiencies of traditional completions. The Premium Liner Hanger has been designed to mitigate risks at critical stages of installation. Both QuickFRAC and Diffusor are ball-activated systems that can reduce nonproductive time and proppant overdisplacement and effectively stimulate the toe of extended-reach laterals.

Packers Plus has offered ball-activated completion design and experience worldwide for more than 15 years. Successfully proven in more than 244,500 openhole stages, the same efficient ball-activated technology also is available for cemented completions.

Recommended Reading

Tech Trends: AI Increasing Data Center Demand for Energy

2024-04-16 - In this month’s Tech Trends, new technologies equipped with artificial intelligence take the forefront, as they assist with safety and seismic fault detection. Also, independent contractor Stena Drilling begins upgrades for their Evolution drillship.

AVEVA: Immersive Tech, Augmented Reality and What’s New in the Cloud

2024-04-15 - Rob McGreevy, AVEVA’s chief product officer, talks about technology advancements that give employees on the job training without any of the risks.

Lift-off: How AI is Boosting Field and Employee Productivity

2024-04-12 - From data extraction to well optimization, the oil and gas industry embraces AI.

AI Poised to Break Out of its Oilfield Niche

2024-04-11 - At the AI in Oil & Gas Conference in Houston, experts talked up the benefits artificial intelligence can provide to the downstream, midstream and upstream sectors, while assuring the audience humans will still run the show.

Haynesville’s Harsh Drilling Conditions Forge Tougher Tech

2024-04-10 - The Haynesville Shale’s high temperatures and tough rock have caused drillers to evolve, advancing technology that benefits the rest of the industry, experts said.