(Source: ReStream Solutions LLC)

It is no secret that there is an ever-increasing number of produced water treatment facilities springing up in the Permian Basin region. As the number of active wells in the Permian, and their respective water cuts, continue to increase, these water treatment facilities will quickly reach maximum capacity. This is taking place in an economic environment where profit margins are thin and future profits are uncertain. For the midstream water market operators, the increasing intensity of market headwinds makes achieving maximum efficiency an absolute requirement for continued survival. With these two factors in mind, how can the chemical analysis and chemical treatment of the produced water be automated? And how is the presentation of the results customized to meet the various different customer-specific formats without additional infrastructure?

The industry has known for many years how to test and treat produced water for disposal and recycling. However, this is a labor-intensive process that bases its results on a manual spot testing and the use of unnecessary human capital. ReStream Solutions fully automated the process with the AquaStream system. The system pulls samples via a slipstream in real time, providing users direct visability into their process chemistries. Data are reported on an ongoing basis in real time. Spot testing cannot match this level of traceability on testing.

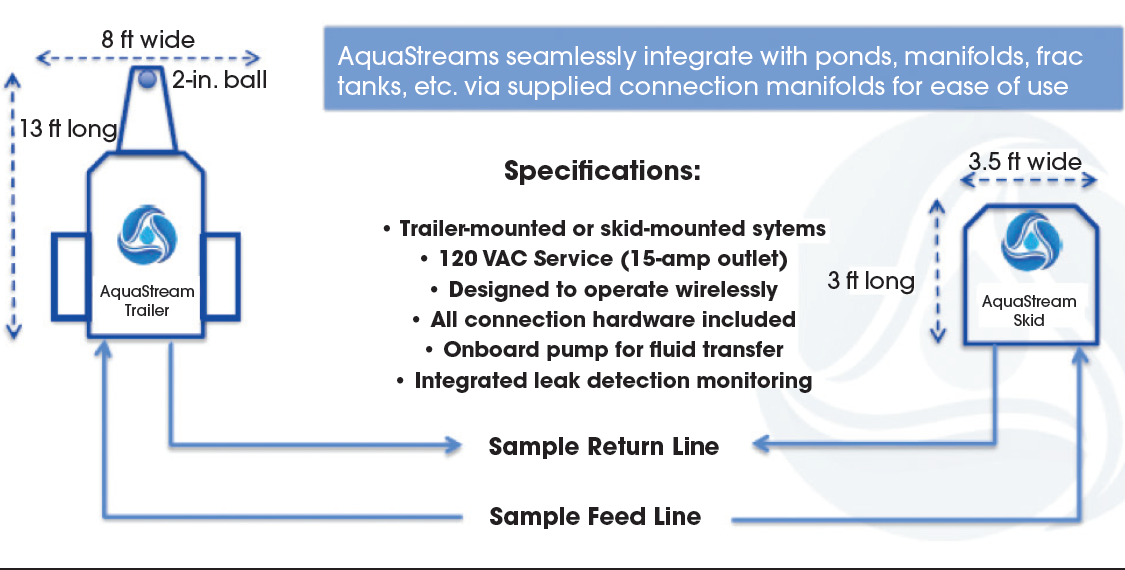

The test trailer occupies a small footprint, requires a 120-V plug-in (15 amps), a sample port and a return port to the produced water line that is to be tested. An automated internal pump and valve system moves fluid through the system and provides isolation, clean-in-place and leak detection capabilities. It can seamlessly integrate with ponds, manifolds, storage tanks or connection manifolds. Rigup times are often as low as 20 minutes. The unit is fully autonomous, unmanned and continuously reports the chemical characteristics of the source water. The data are transmitted locally and to the cloud, where they are accessible by the client.

Data acquisition

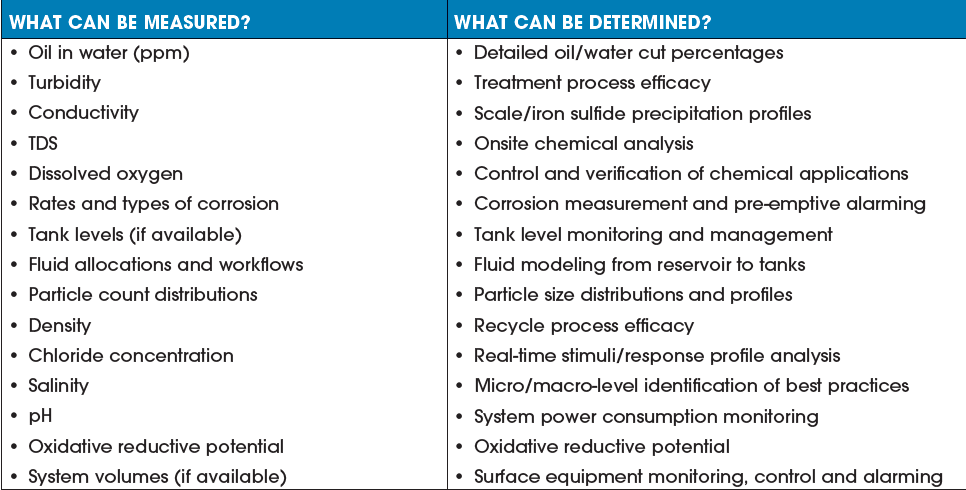

The chemistry data are updated every second while produced water is moving through the system. These data can assist with automated chemical adjustments to deliver a homogenous fluid that is within the specified key performance indicators (KPIs) set by the client (Table 1).

The data are critical to addressing abnormal produced water conditions, the handling of changing and/or commingled produced water sources, conforming to produced water initiatives and more. Once the source water chemistry is measured, a determination can be made as to whether the fluid system KPIs can be achieved through treatment and the normal operation process. If the source water is not economically viable for treatment, the decision to dispose of the water is better informed.

The AquaStream data analytics platform has been used to enable supply chain, water management personnel and completion managers to perform real-time QA/QC analysis to ensure predictable fluid management profiles are met. All of this is accomplished without additional hardware or software infrastructure expenses.

Transparency

AquaStream data sets and visualizations are fully customizable and capable of being integrated into any customer’s data management infrastructure, SCADA system or internal reporting system. The customized data files are available anytime and are designed to be integrated with FracFocus, state-regulatory commission reports or clientspecified datasets.

In addition, ReStream Solutions offers the use of its reporting system as part of the Aqua-Stream system. The system’s automated reporting decreases field level and engineering workloads and provides quick reference formats to look for trends such as recycle efficiency and total dissolved solids. Reports can be scheduled hourly, daily or weekly.

Third-party data

ReStream Solutions does not advocate any processes nor sells any chemicals or water treatment equipment. It provides chemical analysis on the clients’ source water. It can be relied on to provide unbiased data on the water chemistry as it flows through the associated infrastructure. Clients often use AquaStream data to identify best practices and refine operational efficiencies. The system is routinely used by clients to determine the cost effectiveness of various competing chemical offerings and treatment stategies.

Sophisticated chemical analysis equipment requires skilled maintenance personnel and an aggressive maintenance schedule. AquaStream personnel perform maintenance and calibrations of the probes on a scheduled basis, and monitor the sensors continuously to ensure accuracy. There are no additional costs associated with the mobilize/demobilize process, hookup, maintenance, calibration and replacement of probes, software and engineering when using the Aqua-Stream system.

Market headwinds are pressuring every sector of the industry to become more efficient, and the midstream water market is no exception. Financial success (and long-term survival) will be achieved by lowering operational costs and treating more barrels of water at a lower overall cost. Accurate chemical analysis coupled with automation are the first steps to achieving that goal.

Recommended Reading

BP’s Kate Thomson Promoted to CFO, Joins Board

2024-02-05 - Before becoming BP’s interim CFO in September 2023, Kate Thomson served as senior vice president of finance for production and operations.

Magnolia Oil & Gas Hikes Quarterly Cash Dividend by 13%

2024-02-05 - Magnolia’s dividend will rise 13% to $0.13 per share, the company said.

TPG Adds Lebovitz as Head of Infrastructure for Climate Investing Platform

2024-02-07 - TPG Rise Climate was launched in 2021 to make investments across asset classes in climate solutions globally.

HighPeak Energy Authorizes First Share Buyback Since Founding

2024-02-06 - Along with a $75 million share repurchase program, Midland Basin operator HighPeak Energy’s board also increased its quarterly dividend.

Occidental Increases Annual Dividend by 22%

2024-02-11 - Occidental Petroleum Corp.’s newly declared dividend is at an annual rate of $0.88 per share, compared to the previous annual rate of $0.72 per share.