To make a clear case for how seal welding technology can substantially reduce downtime and provide significant cost savings for FPSO vessels, it is helpful to first assess the estimated cost of that downtime. What types of investments are usually involved in running an FPSO vessel?

According to an oil and gas expert at ABS Consulting, estimating a realistic value can be deduced by simply taking the FPSO vessel’s day rate and doubling it to take into account transportation services, rentals, communication services, drilling services, support services, security services, shore-based support and all the other myriad items.

For example, if an FPSO rate of $500,000 per day has an average “spread” cost of $1 million per day, then the assumption can be made that the hourly costs are about $42,000. Two hours of downtime would be a loss of $84,000. If you dive in deeper and calculate the per-minute impact, then the cost is $700 per minute. A $700-per-minute loss due to downtime can add up very quickly.

Certainly less expensive FPSO units will have proportionally lower support costs, but the approximation is still close enough for the purposes of assessing the costs of downtime in general.

The offshore oil and gas sector has more applications that have evolved to accommodate the growing and demanding offshore needs to drill deeper and reach farther, which has led to increased use of enhanced FPSO vessels to extend business opportunities and derive additional value. There are currently about 225 FPSO vessels in use worldwide. Many FPSOs stay in situ for years.

Overcoming obstacles

FPSO vessels have become economically attractive for use in smaller oil fields, which quite often can be exhausted in a few years and do not justify the expense of installing a pipeline. Additionally, maintaining these installations often can prove difficult and time-consuming, especially as environments at deeper depths can become more demanding.

When onshore maintenance of the FPSO is required, the cost of shutdown and traveling time required to return an FPSO vessel to shore can add up very quickly. Offshore operators are continually on the lookout for ways to reduce the need for shutdown to avoid the associated downtime.

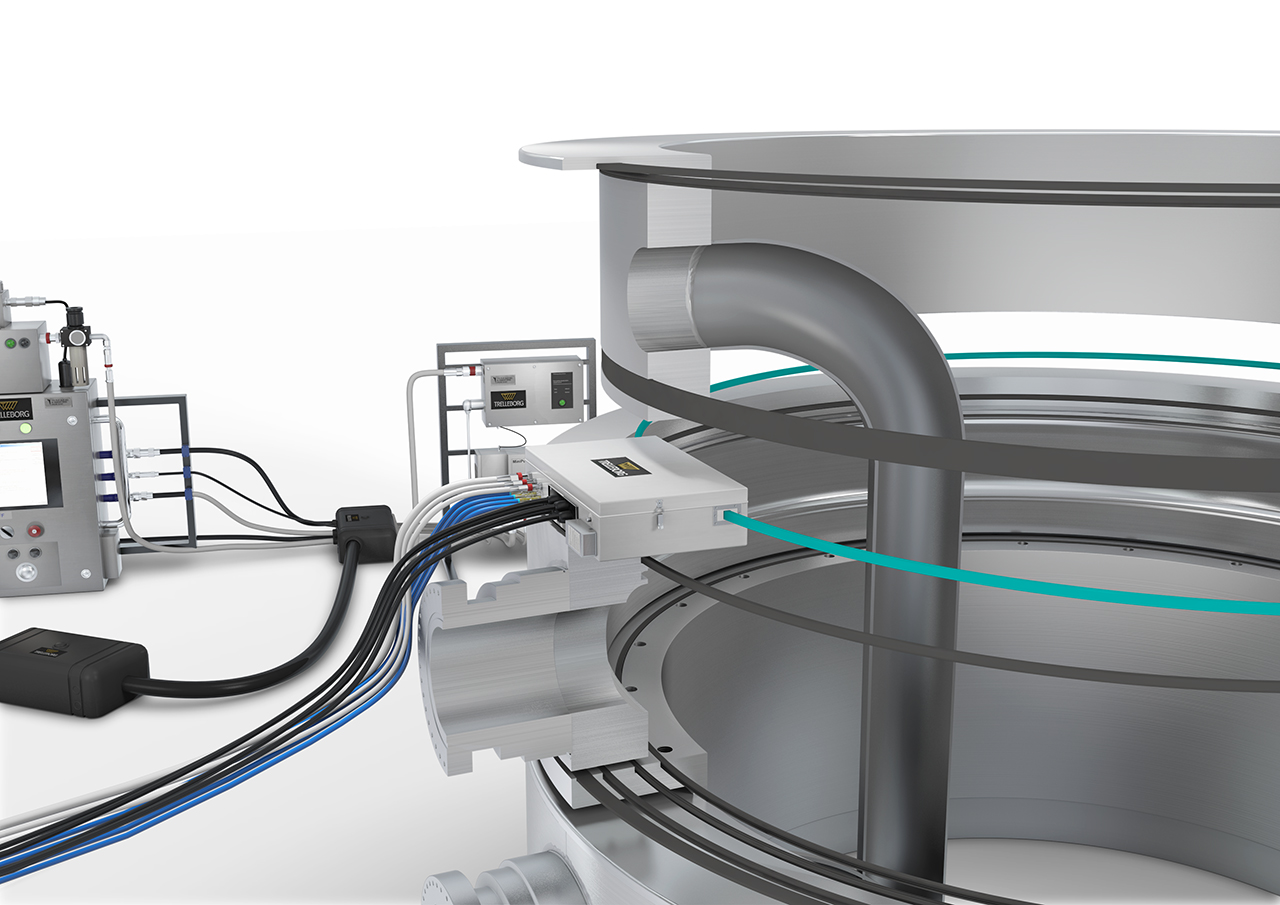

A critical element onboard an FPSO facility, the swivel stack, is the heart of the turret, mooring and fluid transfer system. The swivel stack ensures that all fluids, controls and power are transferred safely from the geostationary components to the rotating vessel and its process plant under any environmental conditions.

Seals are vital when it comes to ensuring the efficient and safe operation of a swivel stack. The seals within the swivel stack are of various diameters. They’re engineered to withstand arduous conditions and to be compatible with aggressive media, using high-specification materials such as polytetrafluoroethylene compounds and advanced elastomers specifically developed for oil and gas processing.

Swivel stack seals are usually specified to have a life expectancy of 25 years, and if correctly engineered, this objective is generally met. However, there are situations when seals fail before the 25-year target and need replacement.

Failure of the seal is commonly indicated by leakage. Simply replacing the seal will not solve the issue, and seal experts should be called in to identify the root cause. This might be that the seal was not specified correctly in the first place or the result of outside impact such as grit in the pipeline at a particular field.

Trelleborg Sealing Solutions is working with numerous operators on a daily basis to solve swivel-stack sealing issues. Some seals have needed to be regularly replaced within several months of fitment. Engineering the seals for the applications solved these problems and, with the added benefit of replacement onsite, the solutions provided short- and long-term savings for operators.

Saving downtime

Replacement of the seals in a swivel stack usually requires the FPSO unit to travel back to shore so that components can be completely disassembled and seals replaced. This operation is extremely time-consuming and requires huge preparation time, meaning the FPSO vessel can be down six to 12 weeks.

Repair of the seal on the FPSO unit not only alleviates traveling time back to shore but also cuts the time required to replace the swivel stack seal from two weeks to one week. In addition, subsea flowlines can remain connected; disconnection normally requires a couple of days to get the pressures right. The risk of potential problems that can come with disconnecting equipment and moving the vessel also are mitigated.

With every second saved in downtime being an addition to the bottom line of the operator, cutting out the traveling time required to return an FPSO unit to shore and the time to disconnect and reconnect plus the seal replacement can provide operators with huge financial savings in downtime.

Straightforward concept

The solution to the issue of offshore seal maintenance might seem like an obvious one—to provide a solution that would allow removal and replacement of seals on the FPSO unit offshore. However, to do this and create a technique that would fulfill this seemingly straightforward idea was complex to achieve.

Expert seal engineers set forth to develop a technique that would bond the ends of a cut seal offshore, which would prove extremely arduous to do. Complicating matters, preferably the seal welding should take place when other swivels are still in production. With a lot of risk to be mitigated, specialized safety features needed to be incorporated into the welding equipment. The equipment needed to be portable so it could be transported relatively easily to the FPSO vessel. Also, for safety and compliance requirements, a dedicated and well-trained service team would be required to go offshore to perform the operation.

To meet the requirements of offshore operators, the company has developed a viable, fully tested portable system that will replace seals in situ. This allows seals to be welded in situ on FPSO vessels, eliminating the need for the vessel to disconnect and return to shore.

Fully compliant solution

The SealWelding process begins in a controlled manufacturing environment where the seal is produced and then cut in one place using a specially designed tool. It is then packed carefully to ensure it is protected to avoid damage in transit.

Once the product arrives onboard the FPSO vessel, it is unpacked and installed by trained personnel onto the swivel stack into the weld head enclosure, which is then pressurized so that the welding can take place. Fully enclosed, production on other swivel stacks can continue without risk.

A control cabinet, which is purged and certified to Atmospheres Explosibles Directive Zone 1, ensures a smooth process. It monitors and logs all data as a part of a procedural audit. When complete, the seal is removed, polished and then checked. If the values from the recorded data are satisfactory, then the seal will be released for installation.

It is important to use a proven material as opposed to a modified substance to avoid integrating something that has not been fully tested into the new system. Offshore operators quite often double-check to ensure full compliance and reliability of the material.

The end result offers a technology process where operators can realize significant savings by maintaining seals offshore. This further enhances the already economically attractive FPSO solutions, especially for addressing the needs of smaller oil fields.

Recommended Reading

NextEra Energy Dials Up Solar as Power Demand Grows

2024-04-23 - NextEra’s renewable energy arm added about 2,765 megawatts to its backlog in first-quarter 2024, marking its second-best quarter for renewables — and the best for solar and storage origination.

Halliburton’s Low-key M&A Strategy Remains Unchanged

2024-04-23 - Halliburton CEO Jeff Miller says expected organic growth generates more shareholder value than following consolidation trends, such as chief rival SLB’s plans to buy ChampionX.

Enverus: 1Q Upstream Deals Hit $51B, but Consolidation is Slowing

2024-04-23 - Oil and gas dealmaking continued at a high clip in the first quarter, especially in the Permian Basin. But a thinning list of potential takeout targets, and an invigorated Federal Trade Commission, are chilling the red-hot M&A market.

Baker Hughes Awarded Saudi Pipeline Technology Contract

2024-04-23 - Baker Hughes will supply centrifugal compressors for Saudi Arabia’s new pipeline system, which aims to increase gas distribution across the kingdom and reduce carbon emissions

Ithaca Energy to Buy Eni's UK Assets in $938MM North Sea Deal

2024-04-23 - Eni, one of Italy's biggest energy companies, will transfer its U.K. business in exchange for 38.5% of Ithaca's share capital, while the existing Ithaca Energy shareholders will own the remaining 61.5% of the combined group.