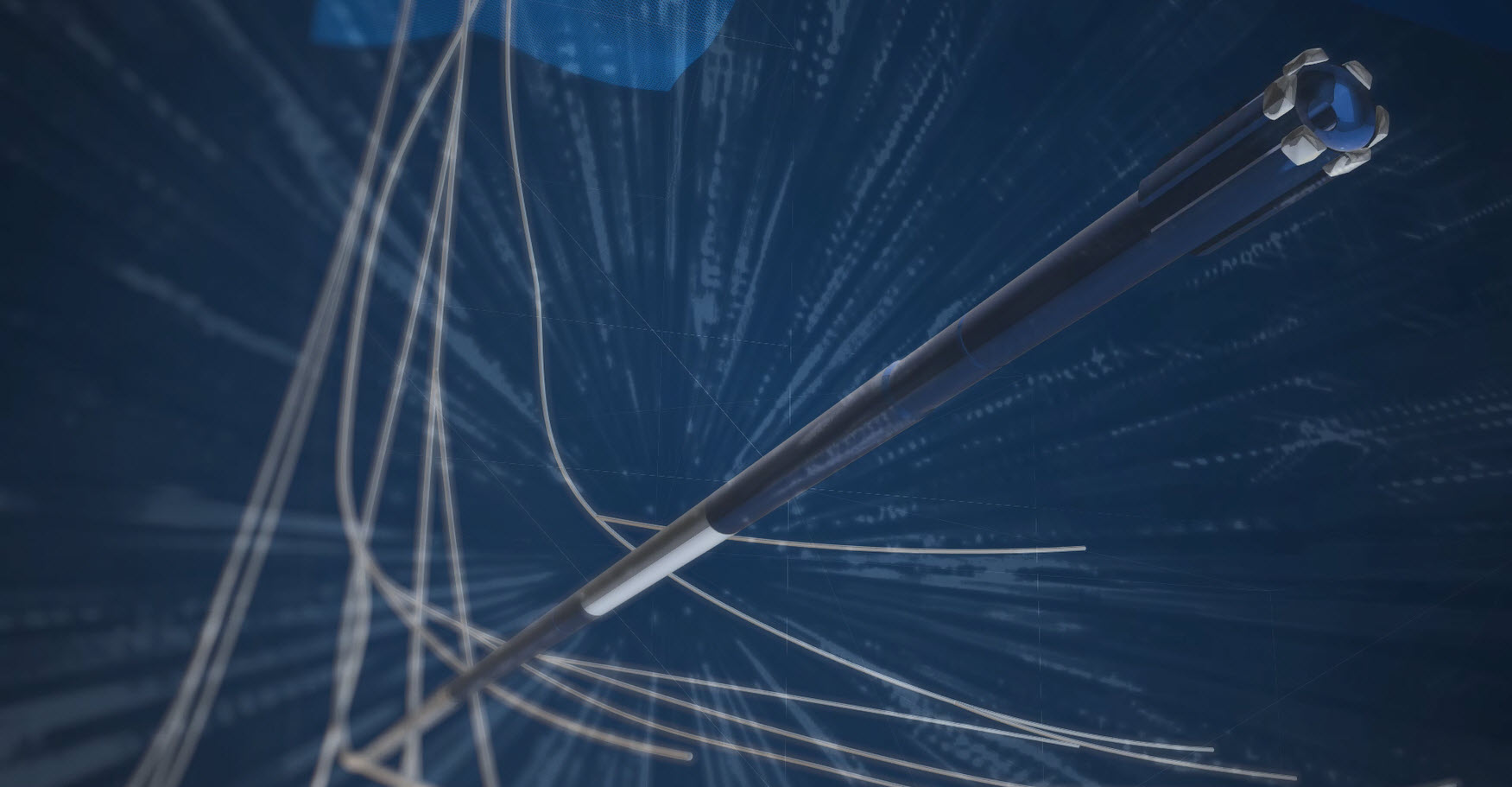

The BHGE xSight casing collar locator detects and visualizes casing collars in real time while running in-hole on drillpipe. In this application, the service identified casing collar locations in two intervals of 7-in. liner in real time. (Source: BHGE)

With well complexity increasing and margin for error shrinking, well intervention operations have become more challenging, time-consuming and expensive. Conventional intervention approaches, which are largely experience-based and involve significant guesswork, are often inadequate. The use of surface gauges to measure weight, torque and pressure in deep and highly deviated offshore wells typically do not reflect downhole realities, which often lead to decreased operational efficiencies and increased risks.

Because of these challenges, the industry realized that downhole intelligence was needed to maximize efficiency and consistency, reduce operational risks and ultimately optimize production. In response, Baker Hughes, a GE company (BHGE), released its xSight smart intervention services. The services provide greater clarity and precision for intervention jobs by delivering live downhole data, remote monitoring and operations, real-time analytics, and digital data processing and visualization.

Comprehensive analysis

This drillpipe-deployed smart intervention system comprises a number of components that work in tandem to provide real-time downhole insights to optimize well intervention operations.

The system has downhole sensors that measure critical operating parameters including weight on bit (WOB), torque, annular pressure, bore pressure, temperature, bending, tool orientation and casing collar location. It also includes a downhole power and bidirectional communication system that powers downhole electronics and sensors and enables real-time data transmission. Its bi-directional communication system includes downhole mud pulser and surface systems for downlinking and decoding. In addition, the software package processes and visualizes downhole data while subject matter experts are on 24/7 standby to review job data and provide technical support.

The system’s real-time WOB, torque, rpm and vibration readings are designed to increase job efficiency in a range of intervention applications, including lightweight fishing and object retrieval, wellbore cleanup, milling and whipstock casing exits.

Case study

In early 2017 an operator in the North Sea selected xSight for a plug-and-abandonment (P&A) and slot recovery operation. The original well was drilled in 1990 and recently ceased production, and the intervention operation was planned to drain remaining oil from another target.

Several factors made this operation high risk. A 95⁄8-in. casing installed during initial well construction subsequently leaked, and the currently installed casing had a thinner wall (43.5 lb) than normal (53.5 lb). In addition, casing wear was estimated to be 10% to 21% from the drilling phase of the well. No casing tally was available from the rig, and uncertainties in casing and liner condition existed because of aging.

The well was deep and deviated, with a 95⁄8-in. casing shoe at 4,326 m (14,193 ft) with a 65-degree inclination and a 7-in. liner ending at 4,777 m (15,673 ft) with a 62-degree inclination, both of which further increased the risks and uncertainties of the intervention operation. In 2013 a wireline-deployed bottomhole assembly (BHA) was unable to pass at a measured depth of 4,587 m (15,049 ft). If the whipstock casing exit operation could not be performed successfully in a 7-in. liner, a contingency target and well path would not be available.

BHGE deployed the smart intervention system in four different runs to mitigate risks and optimize the operation. The first run was dedicated to milling out and retrieving the 95⁄8-in. production packer. In this operation, a packer milling BHA containing the smart intervention system was run in-hole tagging the packer at 4,159 m (13,645 ft). During this run, downhole WOB, torque and pressure were monitored in real time to optimize the milling operation.

Milling started with a 80 rpm, 31 torque and 1 to 3 tons WOB. The pump pressure increased to 190 bar, and WOB increased to 10 tons, which indicated milling of the packer element. Milling continued until the downhole pressure readings detected total losses, after which the pump was shut down and milling continued until the packer fell. Then the packer and tailpipe were pulled out of hole and magnets were used to fish out debris left in the 95⁄8-in. casing and 7-in. liner.

The next two runs, which were designed to drift clean the 7-in. liner, deployed the smart intervention system to log casing collars and to monitor downhole parameters in the event that obstructions were encountered. Casing collars were logged in two intervals and in two separate runs in the 7-in. casing to identify the optimal depths for setting the production packer and whipstock.

The two intervals were logged with similar operating parameters: a logging speed ranging from 39.6 m/hr to 60.9 m/hr (130 ft/hr to 200 ft/hr), with a rotation between 40 rpm and 80 rpm and a flow rate between 800 liters and 1,300 liters per minute.

Casing collars were identified during both logging runs. The collar log in the lower interval—from 4,510 m to 4,569 m (14,797 ft to 14,990 ft)—confirmed casing collars at depths of 4,522 m (14,836 ft), 4,534 m (14,875 ft), 4,546 m (14,914 ft) and 4,558 m (14,954 ft). Based on these data, a setting depth of 4,571 m (14,997 ft) was considered optimal for the whipstock. During these two runs, WOB, torque and pressure readings were monitored in real time to optimize the 7-in. liner cleanout runs. While attempting to pass through a restriction at 4,570 m (14,994 ft), the downhole WOB data helped the operator decide to pull out of hole and avoid damage to the BHA.

The final run, a 7-in. whipstock casing exit operation, used xSight to optimize the whipstock setting and casing window milling processes. During the process of orienting and setting whipstock as well as breaking the milling BHA free with the whipstock, real-time weight and torque data were monitored and used to ensure successful execution. Operational parameters were adjusted during the run based on real-time downhole insight, with monitoring and real-time advisory services from the remote operations support center. The milling operation went smoothly.

Despite the challenging nature of the well and the various risks and uncertainties of the operations, the smart intervention system provided timely and high-quality decision-making to be made throughout the intervention, resulting in zero nonproductive time. The casing collar locator service provided by the smart intervention system identified casing collar locations in two intervals of the 7-in. liner in real time. This led to the decision of the proper setting depth for the whipstock and production packer, saving two dedicated wireline runs and multiple days of rig time in the process.

In addition, the system’s critical downhole parameters improved efficiency and ensured success in casing window milling, which contributed to achieving the overall operational objective of reaching another target to drain additional oil because a contingency target could not exist if the casing exit operations failed in the 7-in. liner.

Conclusion

As the xSight system continues to optimize intervention operations in challenging and risky wells, more operators are investigating its applicability in their own fields. The delivered real-time downhole insights and ongoing migration from experience-dependent execution to data-driven solutions promise to move the industry closer to its goal of executing well interventions with the highest degree of precision, control and intelligence.

Recommended Reading

US Drillers Add Oil, Gas Rigs for First Time in Five Weeks

2024-04-19 - The oil and gas rig count, an early indicator of future output, rose by two to 619 in the week to April 19.

Strike Energy Updates 3D Seismic Acquisition in Perth Basin

2024-04-19 - Strike Energy completed its 3D seismic acquisition of Ocean Hill on schedule and under budget, the company said.

Santos’ Pikka Phase 1 in Alaska to Deliver First Oil by 2026

2024-04-18 - Australia's Santos expects first oil to flow from the 80,000 bbl/d Pikka Phase 1 project in Alaska by 2026, diversifying Santos' portfolio and reducing geographic concentration risk.

Iraq to Seek Bids for Oil, Gas Contracts April 27

2024-04-18 - Iraq will auction 30 new oil and gas projects in two licensing rounds distributed across the country.

Vår Energi Hits Oil with Ringhorne North

2024-04-17 - Vår Energi’s North Sea discovery de-risks drilling prospects in the area and could be tied back to Balder area infrastructure.