Learn more about Hart Energy Conferences

Get our latest conference schedules, updates and insights straight to your inbox.

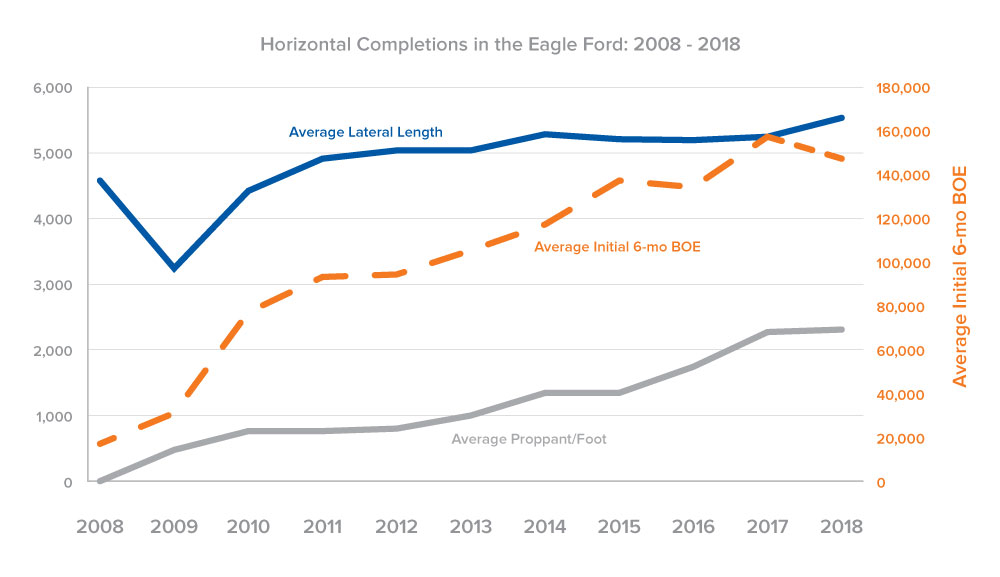

The trend toward longer laterals, higher proppant loads, tighter stage spacing and higher stage counts have all contributed to better operational efficiency and higher production.

However, optimization has reached a tipping point where gains are offset by potential trade-offs. For any completion system, the same proppant that improves production—especially at high volumes—also can erode downhole tools to the point of failure, resulting in expensive remedial solutions or lower production, and potentially both.

Fortunately, these issues have been specifically mitigated for both single-point and limited-entry completions by reducing fluid friction, mitigating ball/seat and entry point erosion, and enhancing quality control to increase reliability.

Pain points

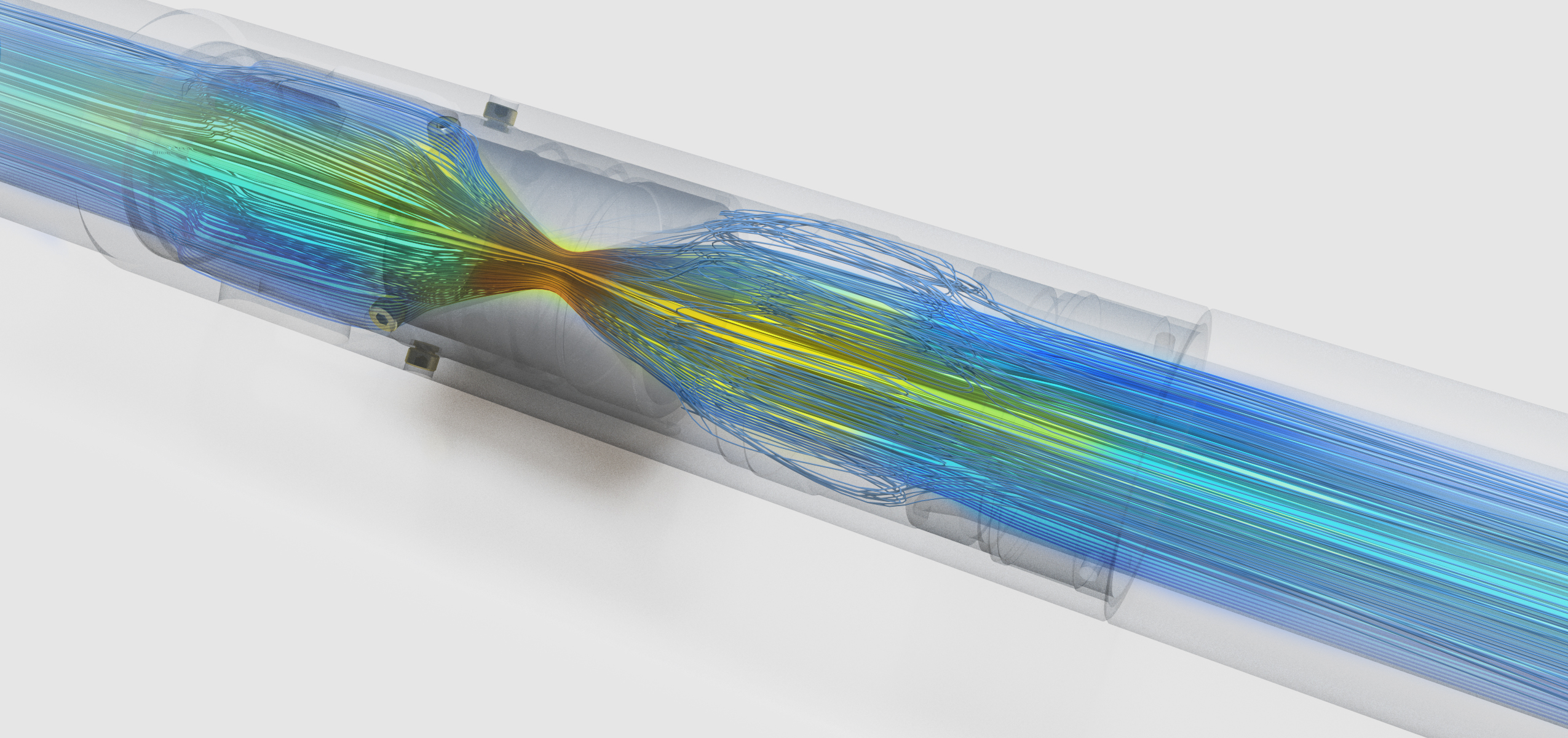

The turbulence of fluid flow through a seat causes a slight pressure increase. This is inconsequential for one seat, but a completion string of 40 to 50 sliding sleeves can add thousands of pounds of pressure of additional friction, which is a source of operational concern.

During stimulation, a ball and seat combination isolates one fracturing stage from another with less than 1/16 in. of diametric difference between the ball and seat. The ability to hold pressure on these edges is critical to the success of the completion.

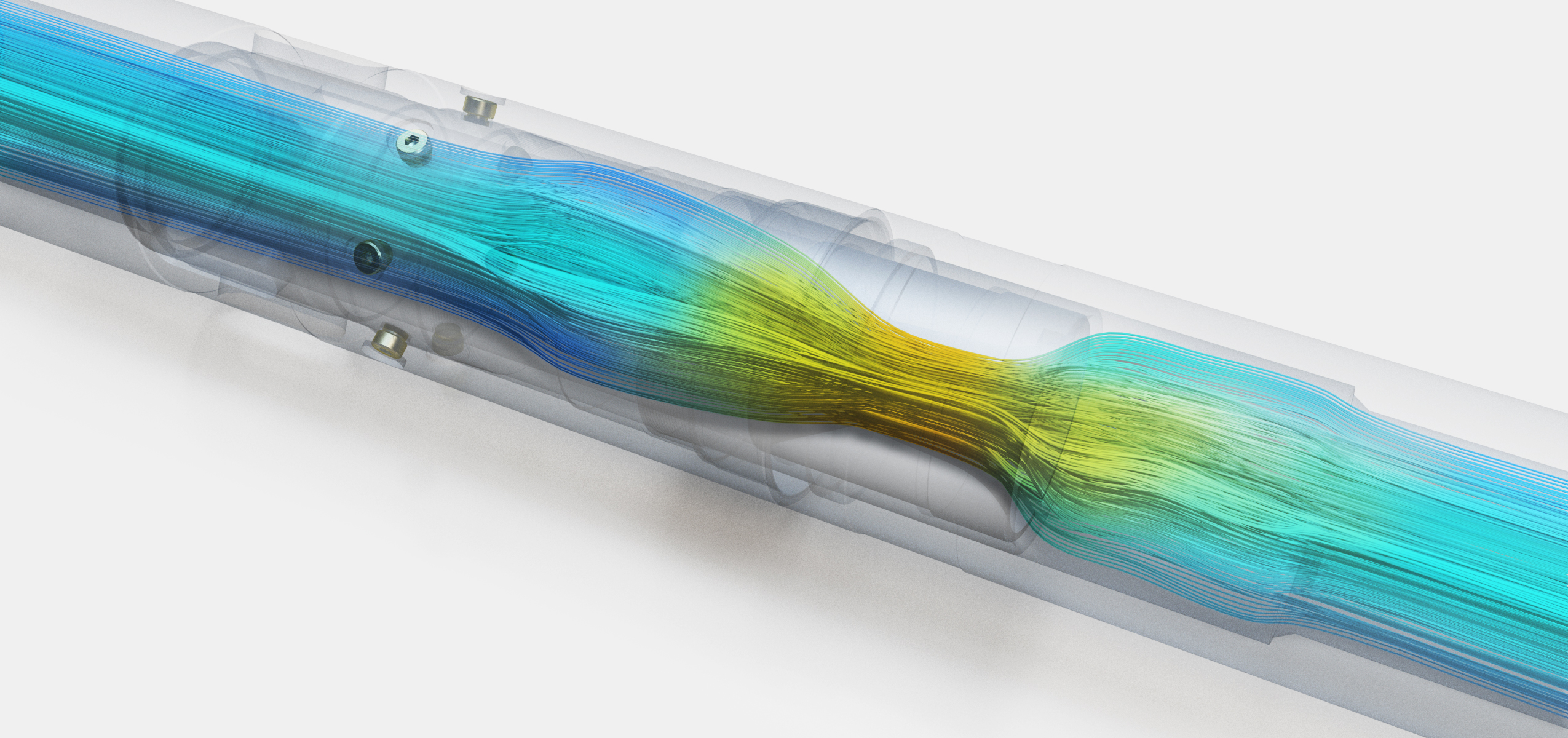

In plug-and-perf (PNP) liners, a pressure drop decrease is observed as soon as the slurry reaches perforations. This is caused by proppant eroding and enlarging the perforations. With the first perforations accepting most of the fluid, others in the same interval receive minimal or no treatment.

Mitigation

Technological innovation has led to several solutions that strike a balance between a high-proppant stimulation and failure due to erosion. These were designed specifically to mitigate erosion to give operators the confidence to execute high-volume proppant completions.

Reducing fluid friction. Sliding sleeves have been redesigned to mitigate cumulative fluid friction. Using computational fluid dynamics simulation, the reshaping of the internal fluid path has reduced pressure drop (and thus fluid friction) by more than 60%.

This design has been implemented throughout Packers Plus product lines and also has lowered obstacles to stage count limitations by allowing smaller seat increments in the StackFRAC HD-X multistage system and TREX limited-entry and single-point entry systems.

In a move toward custom-sized increments, StackFRAC HD-X improves on the industry standard of 1/16 in. These systems are capable of up to 70 single-point entry stages (on a 4.5-in. liner), where all seats are designed to withstand 6,000 psi of differential pressure.

Production logging also has shown that only 20% to 50% of the intended fracturing targets in a perforation cluster were producing at fracture-stimulated rates. This inefficient use of proppant leads to lower than expected production and lower return on investment.

The TREX limited-entry system uses a single actuation ball to pass through multiple QuickPORT IV sleeves. These sleeves also have been redesigned with 40% fewer moving parts than previous versions, mitigating the risk of failure due to sand buildup or erosion.

Mitigating seat and entry-point erosion. The interference of a ball and seat is essential to old pressure so that each stage can be treated. However, conventional metallurgy combined with high-proppant volumes can lead to seat erosion.

To address this issue, harder alloys have been implemented to reinforce ball seats and other critical points along the slurry flow path. For ultrahigh-proppant stimulations, hardened anti-erosion coatings also can be applied on the inner surface of sleeves.

For limited-entry point systems, to avoid the uneven fluid distribution throughout a cluster as often seen in PNP, the QuickPORT IV ports are reinforced with tungsten carbide. This facilitates a consistent distribution of treatment among the entry points.

Enhancing quality control to increase reliability. A great design is barely worthwhile if it isn’t consistent. In recognition of this, Packers Plus ensures that from design through manufacturing, assembly, testing, shipping and installation, a fully integrated ISO 9001 and American Petroleum Institute Specification Q1 process is followed to ensure reliability on every well.

To achieve consistent precision, all tools can be measured to within 0.0001 of an inch. Some other examples of this quality process are

• Automated torque testing and pressure testing up to 15,000 psi;

• Balls are scanned using ultrasonic and 3-D lasers for surface defects, ovality, thickness and dimension with 0.003-in. tolerance;

• For full traceability, each tool is imprinted with a unique bar code that stores data, such as material and dimensions, test results, inspections, shipping and downhole position; and

• Experienced field hands are on location to manually check the size and order of tools during installation and stimulation.

These precautions are intended to provide reliability that reduces the possibility of the cost and risk of downtime during operations.

Case studies

An operator developing acreage in Utah wanted to increase stage counts to achieve the best reservoir coverage and production economically. The operator wanted to improve efficiency from PNP by using a continuous pumping system, which would eliminate millout and allow a fast turnaround to production.

A 51-stage StackFRAC HD-X system was installed in a well with a 3,038-m (9,970-ft) lateral. Since the operator also planned an aggressive treatment at pumping rates more than 50 bbl/min, an erosion analysis was required. The analysis estimated that erosion would be well below maximum design limits.

The stimulation was done successfully, with all 51 stages treated as planned.

In another case study, an operator working in the Permian Basin had been using a standard hybrid completion for wells exceeding 6,096 m (20,000 ft) of measured depth (MD). These wells were run using five groups of four QuickPORT IV ball-activated sleeves at the toe, successfully eliminating operational risks associated with wireline at those depths, while simultaneously removing entry-point erosion common to limited-entry stimulation. The upper stages were completed using PNP.

For a particularly long well with a 7,101-m (23,300-ft) MD, 20 sleeves were insufficient to cover the last 1,188 m (3,900 ft) of the lateral. Eighty QuickPORT IV sleeves were installed, grouped into 20 stages. All 20 stages were stimulated in under 70 hours of pumping time.

The operation proves the effectiveness of the TREX QuickPORT IV limited-entry system for reducing operational risk as well as its ability to perform as an extended-lateral, high-density proppant completion solution.

The future innovates

Because higher proppant volumes have been correlated to better production, stimulation programs in North America now routinely pump hundreds of thousands of pounds of proppant per stage. These technologies have enabled operators to push the boundaries of unconventional oil and gas completions to increase well productivity. Packers Plus completion systems have been specifically designed to meet this challenge, striking a balance between a proppant-heavy stimulation and cost-effective systems that prevent failure due to erosive tool damage.

References available. Contact Brian Walzel at bwalzel@hartenergy.com for more information.

Recommended Reading

Exxon Mobil Guyana Awards Two Contracts for its Whiptail Project

2024-04-16 - Exxon Mobil Guyana awarded Strohm and TechnipFMC with contracts for its Whiptail Project located offshore in Guyana’s Stabroek Block.

Deepwater Roundup 2024: Offshore Europe, Middle East

2024-04-16 - Part three of Hart Energy’s 2024 Deepwater Roundup takes a look at Europe and the Middle East. Aphrodite, Cyprus’ first offshore project looks to come online in 2027 and Phase 2 of TPAO-operated Sakarya Field looks to come onstream the following year.

E&P Highlights: April 15, 2024

2024-04-15 - Here’s a roundup of the latest E&P headlines, including an ultra-deepwater discovery and new contract awards.

Trio Petroleum to Increase Monterey County Oil Production

2024-04-15 - Trio Petroleum’s HH-1 well in McCool Ranch and the HV-3A well in the Presidents Field collectively produce about 75 bbl/d.

Trillion Energy Begins SASB Revitalization Project

2024-04-15 - Trillion Energy reported 49 m of new gas pay will be perforated in four wells.