The background color shows the cumulative volume of saltwater injected into the Arbuckle Formation between 2009 and 2015 in different areas of Oklahoma. The saltwater injection volume has been calculated within a radius of 0.5 degrees around a given location on the map and is plotted at the center of the areas. Historic earthquakes (1979-2008) are shown as black circles, and recent earthquakes (2009 to September 2016) are presented as gray circles. Colored stars show the locations of recent M ≥ 4.5 earthquakes. (Source: Stanford University)

One need merely to look at a map of Oklahoma with an overlay of recent earthquakes to realize that there might be a problem there.

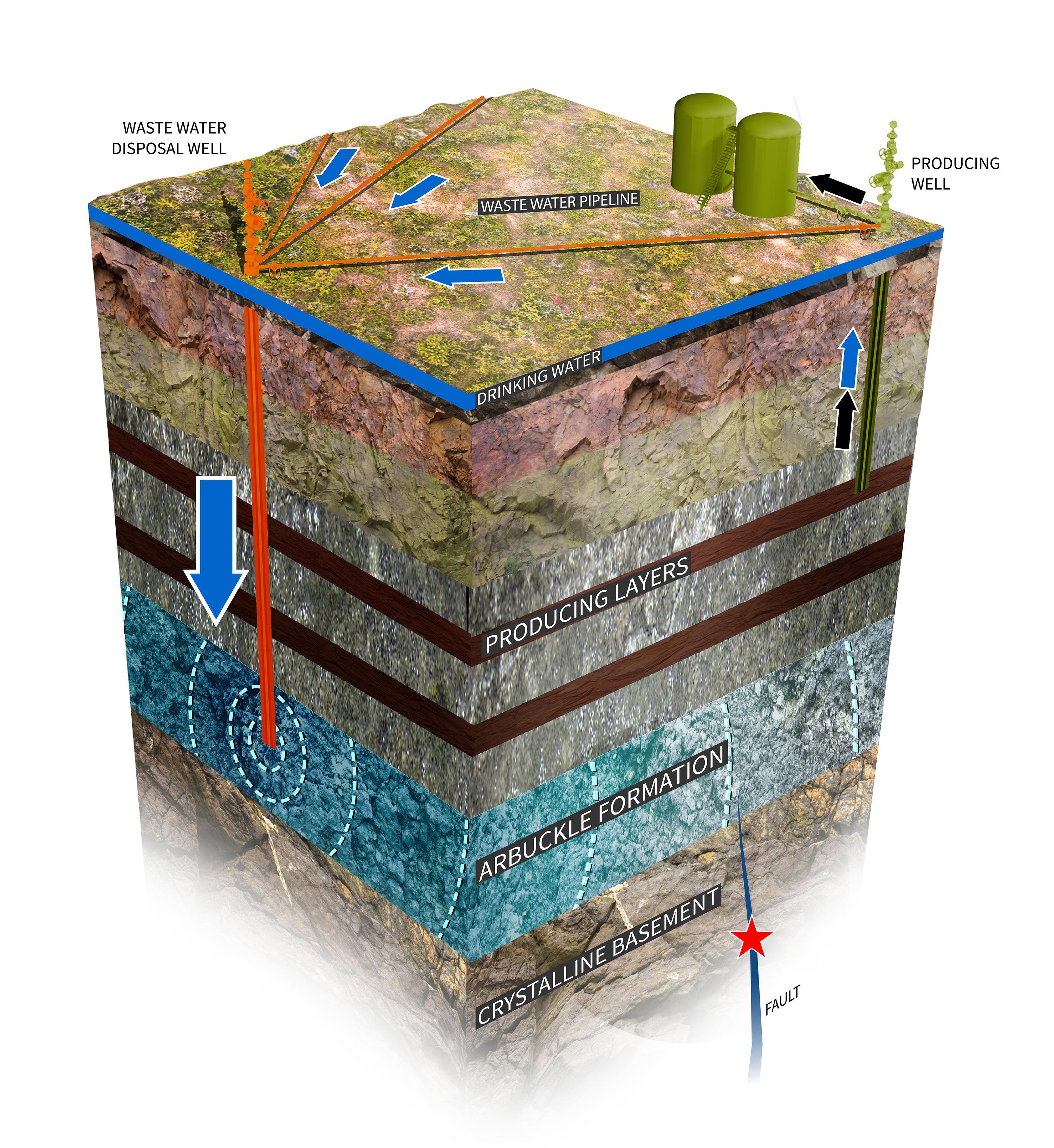

In areas so far from the seismically active edges of the great tectonic plates, a rapid increase in earthquakes over a relatively short period of time is cause for some concern. Mark Zoback, Benjamin M. Page Professor of Geophysics and director of Stanford University’s Natural Gas Initiative, recently gave a presentation to the National Academy of Sciences showing that the dramatic increase in earthquakes in Oklahoma that started accelerating in 2009 corresponds quite neatly with an uptick in unconventional gas and oil drilling in the state. Zoback reported that in Oklahoma it wasn’t the drilling or hydraulic fracturing that was triggering the quakes—it was the injection of produced water back underground.

The earthquakes that have plagued Oklahoma in recent years have in many cases been due to produced water coming from the Mississippi Lime and other formations and being injected back into the Arbuckle Formation, a thick, porous and highly permeable carbonate formation that intersects with basement faults. While saltwater injection is nothing new in the oil field, the quantities of water have grown rapidly, totaling 3 Bbbl over the past few years, Zoback said. And pressure changes of less than 100 psi are enough to cause potentially active faults to slip.

Identification and avoidance

Identification and avoidance

While most of the earthquake activity in Oklahoma has not caused damage or injury, several recent quakes have registered 5 or higher on the Richter Scale, a level at which damage can occur. But how do companies know how to avoid these potentially active faults?

Zoback and his colleague Rall Walsh set out to solve this puzzle. “We were studying induced seismicity pretty intensively for the last four years after things started to pick up in the U.S. and especially Oklahoma,” Zoback said. “Our first major paper was published in June 2015 and showed the close spatial correlation between the previous water injection wells in north-central Oklahoma and the areas where the seismicity was occurring.”

Zoback told the audience that knowing the stress state and fault orientation can help determine which faults are more likely to become active due to the pressure of water injection. He and Walsh took a probabilistic approach, attempting to quantify the many uncertainties associated with fault characterization.

Using data from the U.S. Geological Survey (USGS) as well as oil companies in the area, they mapped the orientations of the known faults. Earthquake data from the USGS enabled them to infer stress orientation from groups of earthquakes, and these data show strong correlation with the wellbore data.

Secondly, they used the available fault data to explain the values and the distribution of uncertainties. This information was put into a Monte Carlo simulation to calculate the probability that a fault might slip.

While he said it’s important to identify the faults that are likely problematic, it’s also helpful to identify those that aren’t. The area around Oklahoma City, for instance, has few potentially active faults, which is good to know when injecting vast volumes of water near a highly populated area. The researchers were able to simulate the pressurization of faults in the region to show that they would not slip under pressure.

Unfortunately, many of the faults associated with the earthquakes were not previously known faults. The earthquake near Pawnee, Okla., that occurred in 2016 had a foreshock along a fault that would have been identifi ed as problematic using this methodology, but the main shock occurred on an unmapped fault. Overall, he said, all of the earthquakes that were studied made logical sense; it’s just that an adequate fault map didn’t exist ahead of time.

Next step

To enable the industry to be more mindful of problematic faults, the methodology is available as free software to help calculate the probability of triggering these faults.

“This software allows you to take information about the faults, information that you have obtained for a model of the subsurface, and input how you think the pressure might change,” Zoback said. “You combine these two pieces of information and determine whether or not any of these faults are potentially problematic. It’s like a screening tool.”

Faults in sedimentary sections are easily identifi ed through seismic refl ection surveys, he added. The basement faults are more challenging. “But whenever you have knowledge of a fault, you can use our software to understand whether injection might be problematic and, therefore, decide where you should and shouldn’t place your injection wells.”

The idea of getting the tool in the hands of operators and regulators came from a desire to empower them to be able to apply the same analysis that Zoback and Walsh applied. Zoback noted that the software has to be used intelligently; in other words, the faults have to be known for the tool to be useful. Currently he’s analyzing potentially problematic faults in the Permian Basin using public domain data, but he said companies might also have their own interpretations from which to work.

“It’s important to use the software correctly,” he said. “There are subtleties in assessing risk.”

It remains to be seen who will ultimately “own” the induced seismicity issue. “We’re enabling the work to be done, but whether it’s the operators, the regulators or the disposal companies who most need the tool is unclear,” he said. “But just shooting in the dark isn’t good enough now that induced seismicity is part of the conversation. There are geological regions where it’s not a problem. Where it is an issue, being proactive is better than just waiting to see what happens.

“The industry has been injecting produced water for decades, but when the volume of injection goes up markedly, the industry and the regulatory authorities need to work together to fi gure out how to prevent the wrong things from being done.”

Contact the author at rduey@hartenergy.com.

Recommended Reading

Imperial Expects TMX to Tighten Differentials, Raise Heavy Crude Prices

2024-02-06 - Imperial Oil expects the completion of the Trans Mountain Pipeline expansion to tighten WCS and WTI light and heavy oil differentials and boost its access to more lucrative markets in 2024.

Oil Dips as Demand Outlook Remains Uncertain

2024-02-20 - Oil prices fell on Feb. 20 with an uncertain outlook for global demand knocking value off crude futures contracts.

US Oil Stockpiles Surge as Prices Dip, Production Remains Elevated

2024-02-14 - EIA reported crude oil stocks increased by 12.8 MMbbl as February began, far outstripping expectations.

Oil Settles at Highest in Nearly 8 Weeks on Strong Economic Growth

2024-01-26 - Oil prices settled at their highest in nearly two months on Jan. 26 as positive U.S. economic growth and signs of Chinese stimulus boosted demand expectations.

US Gulf Coast Heavy Crude Oil Prices Firm as Supplies Tighten

2024-04-10 - Pushing up heavy crude prices are falling oil exports from Mexico, the potential for resumption of sanctions on Venezuelan crude, the imminent startup of a Canadian pipeline and continued output cuts by OPEC+.