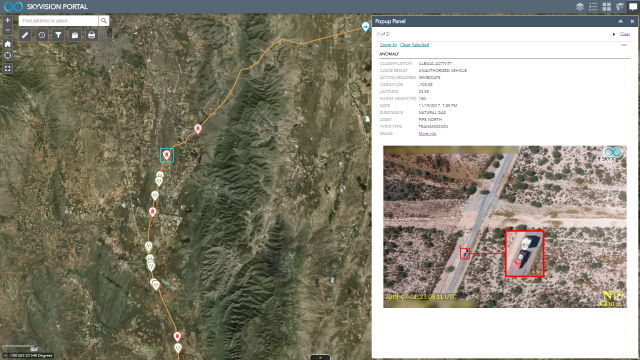

Advanced unmanned aerial vehicles can provide precise information about activity along a right-of-way, such as this pipeline in northern Mexico. Source: SkyX Ltd.

The air is cool as the sun hangs low in the sky. Nighttime draws near. Amidst the rustling of the trees in the wind, there’s a faint buzz. It grows louder. It draws closer. Overhead, a drone flies past.

The drone is inspecting a pipeline right-of-way. Ahead of the drone stretches a corridor of flat land saddled by wild countryside. This is the third and final inspection of the day. From a remote office in a distant city, a pilot-in-command monitors the vehicle as it autonomously performs day-to-day inspections.

As the drone completes this leg of the mission, it lands at a ground station, begins to recharge for the next flight and transmits the captured imagery for analysis. A machine learning algorithm conducting change detection analysis parses through the imagery and identifies two anomalies in a small area. The first is a ground depression—that indicates recent excavation and fill—directly above the pipe. The second anomaly is a set of tire tracks.

Once the anamolies are reviewed by the asset operations team, a ground crew is dispatched to the coordinates, uncovers the pipeline and discovers a small lever valve.

This is an illegal tap, and here are the reasons why you might need drones and artificial intelligence (AI) to stop it.

Product theft

When you think of product theft from a pipeline, your mind likely turns to the extreme, multibillion-dollar losses to brazen theft in countries like Nigeria and Mexico. In the latter country, just one year ago, the world bore witness to the Tlahuelilpan pipeline explosion in the state of Hidalgo, where amidst a fuel theft free-for-all, under geysers of fuel spouting from a pipeline, a static electricity spark triggered an explosion that killed 137 people.

However, illegal activity around pipelines across the globe is becoming far more pervasive and covert in nature.

In Europe, where hydrocarbon theft has historically been a minor issue, illegal activity is skyrocketing. In a five-year analysis of the performance of cross-country European pipelines, a 2018 Concawe report found that approximately 90% of spillage incidents were theft-related. When analyzed against 47 years of historical data, this represents an increase of 150% to 525% in comparison to historical five-year moving averages.

Keep in mind, the true nature of product theft is likely well beyond what we can discern from spills alone, as a successful operation will not result in a pipeline spill.

If pipeline companies operate without the means to adequately detect theft-related activity, amateur or abandoned taps can cause serious damage to the pipeline and surrounding environment.

Besting technology

Sophisticated criminals are getting the best of traditional leak detection technologies. The rampancy of product theft and theft-related spill incidents runs contrary to the gradual reduction in unintentional leaks such as mechanical failures, operational errors, corrosion, natural hazards and accidental third-party activity.

What does this mean? The status quo of leak detection technologies that pipeline asset integrity managers have come to rely on is being outpaced by experienced criminals. From the initial breach of a pipeline to transporting stolen product for sale, a successful product theft operation can conceal itself from numerous points of detection. Here are some of the challenges that operators face:

-

llegal hot taps can go undetected by in-line inspections—To minimize detection during ultrasonic analysis, small pinhole drillings of only a few millimeters in diameter are made into the pipeline, generally too small to trigger an alert. To evade detection from magnetic analysis of pipeline walls, some illegal hot taps utilize nonmetallic components to attach a valve to a line, but another common trend is to use legitimate pipeline fittings against the operator. By installing an illegal tap close to existing fittings, the inspection effort is likely to mistake the hot tap fixture for a normal fitting.

-

Slow siphon rates can deceive SCADA systems—The advantage of using pinhole drillings is twofold for would-be pipeline thieves. Aside from evading in-line inspection tools, siphoning product at a slow rate from these pinholes avoids a substantial pressure change in the pipeline that would trigger an alert by flow measurement systems.

-

Sensor alerts can be difficult to pinpoint—Commonly, leak detection systems only provide a general alert regarding the entirety of a pipeline segment. Once the alert is received, pipeline operators need to pinpoint the specific location of the problem. This can be exceedingly difficult to do on a stretch of underground pipeline that spans miles.

-

Illegal activity can remain well-concealed to the human eye—Criminals can perform the initial hot tap under cover of night to avoid being caught, and the remaining evidence of an excavation can be difficult for a person to spot. Not to mention, careful steps are taken to ensure that the transfer and transport of the product is hidden. While the majority of transfers happen within close proximity to the pipeline, a substantial portion of theft operations run a hose 100 to 1,000 meters away from the pipeline to another area for transfer.

Pipeline operators cannot continue to rely on traditional leak detection technologies if they hope to properly address illegal activity. Criminals are evading sensor systems and exploiting gaps in aerial and ground crew inspections, but operators can level the playing field.

With the shortcomings of in-line technology and traditional methods of visual inspection, operators need to leverage a new echelon of precise, visual data in the fight against illegal activity. Two new technologies that stand to massively benefit pipeline operators in this effort are unmanned aerial vehicles (UAV) and AI. When leveraged together, these two technologies form the backbone of a hyperefficient aerial monitoring workflow that gets you the data you need to identify, pinpoint and deter illegal activity around a pipeline.

A UAV is the textbook definition of efficiency and repeatability for data collection, especially because it can perform missions without human intervention. With the right infrastructure in place, an autonomous UAV can take off from a launch station, fly a segment of pipeline, capture high resolution imagery, land back on a station, transmit data for processing, recharge for the next flight and repeat the process again. All the while, the vehicle flies a precise, programmable flight path that ensures that the visual verification data sets remain consistent from each flight.

Whereas the UAV collects raw data, computer vision software using machine learning algorithms refine it into actionable insights. Machine learning algorithms are faster at analyzing an image and detecting indicators of illegal activity around a pipeline such as people or vehicles, tracks on the ground, excavation sites, construction debris and environmental indicators of a spill.

With every aerial inspection flown and new set of data collected, the software gains a better understanding of what a pipeline and surrounding right-of-way should look like and, by extension, can better detect minuscule anomalies that might merit inspection.

Keep in mind, machine learning technology isn’t magic. It handles the heavy lifting of analysis, but a degree of human verification is required to determine whether a flagged anomaly should be actioned. However, as youcontinue to give the software feedback on what matters and what doesn’t, it gains a better understanding of what to look for and what to ignore. We now start to foray into the realm of predictive analytics.

With the right aerial data solution, operators can gain immediate advantages over would-be pipeline product thieves:

-

Deter hot tapping with frequent inspections—Hot tapping a buried pipeline is a multihour effort. If you’re at high risk for product theft, doing multiple aerial inspections over the course of the day makes it difficult for criminals to tap the pipeline without being caught in the act and increases the likelihood you catch evidence of activity—such as excavation or tracks—while they’re still fresh. An autonomous aerial system provides the operational flexibility needed for frequent deployments.

-

Detect subtle evidence of illegal activity—The combination of consistent aerial data and AI is highly effective at detecting anomalies such as unauthorized persons or vehicles, tracks, construction debris and excavation.

-

Get a bird’s-eye view of a pipeline right-of-way—While the majority of illegal tapping operations live and die in the immediate vicinity of the pipeline, a substantial portion transfer the product hundreds of meters from the pipe for transfer or storage. By flying at higher altitudes, the aerial system can provide a greater field of view of what’s happening around the right-of-way.

-

Pinpoint and verify alerts from SCADA systems—If an attempted hot tap trips a sensor alert, an autonomous aerial system can rapidly dispatch to inspect the affected pipeline segment. With high-quality visual verification data in hand, operators can quickly identify the problem and begin remediation efforts.

-

Counter covert efforts with the right payload—To detect illegal hot tappers who are working under cover of night, or perhaps transferring product to an area with tree cover, infrared sensors can be used to spot them with ease.

Beyond the immediate value in day-to-day inspections, working with consistent visual data in the long-term will allow you to develop predictive analytics that can determine where the next event likely will occur and how to allocate resources for antitheft efforts. Identifying the hotspots of illegal activity and taking action to prevent it will significantly reduce costs associated with stolen product and theft-related damage.

Chuck Goldman is chief revenue officer for SkyX Ltd., a pipeline integrity management firm.

Recommended Reading

NAPE: Turning Orphan Wells From a Hot Mess Into a Hot Opportunity

2024-02-09 - Certain orphaned wells across the U.S. could be plugged to earn carbon credits.

Exxon Versus Chevron: The Fight for Hess’ 30% Guyana Interest

2024-03-04 - Chevron's plan to buy Hess Corp. and assume a 30% foothold in Guyana has been complicated by Exxon Mobil and CNOOC's claims that they have the right of first refusal for the interest.

Petrobras to Step Up Exploration with $7.5B in Capex, CEO Says

2024-03-26 - Petrobras CEO Jean Paul Prates said the company is considering exploration opportunities from the Equatorial margin of South America to West Africa.

The OGInterview: How do Woodside's Growth Projects Fit into its Portfolio?

2024-04-01 - Woodside Energy CEO Meg O'Neill discusses the company's current growth projects across the globe and the impact they will have on the company's future with Hart Energy's Pietro Pitts.

Deepwater Roundup 2024: Offshore Australasia, Surrounding Areas

2024-04-09 - Projects in Australia and Asia are progressing in part two of Hart Energy's 2024 Deepwater Roundup. Deepwater projects in Vietnam and Australia look to yield high reserves, while a project offshore Malaysia looks to will be developed by an solar panel powered FPSO.