Multiple rigs are shown in the Permian Basin. (Source: GB Hart/Shutterstock.com)

The search for the best distance between wells is pushing some operators to wider spacing to avoid interaction between parent and child wells in cube developments, which could impact production and ultimately returns in the Permian Basin.

Several operators spoke on the topic this week during Barclay’s 2019 CEO Energy-Power Conference. Their insight and experiences were shared amid continued shareholder pressure to deliver returns while maintaining capital discipline and efficiency.

“Well spacing and density are one of the great balancing equations of the shale revolution,” Tim Leach, board chairman and CEO of Concho Resources Inc., told conference attendees. “The balance is between rate of return and recovery. So clearly, the higher the density the more molecules we would ultimately recover.”

Concho, a Permian Basin pure-play that operates more than 6,000 wells, decided to make spacing changes after wells drilled as part of tests underperformed in the Delaware Basin.

Many shale players have targeted higher production by placing wells closer together. But that has resulted in less output, in some instances, leading to more conservative spacing.

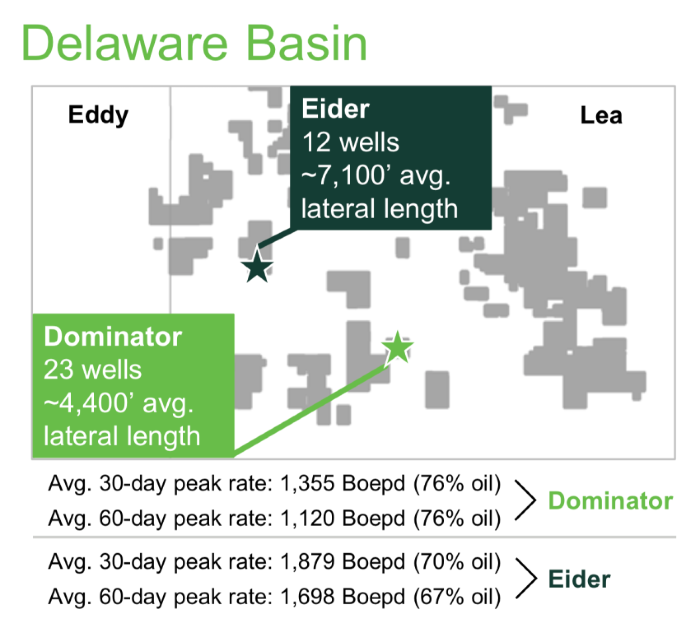

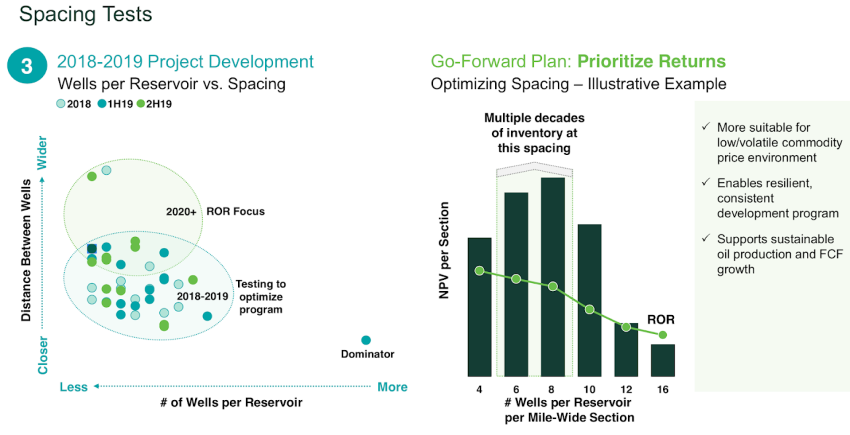

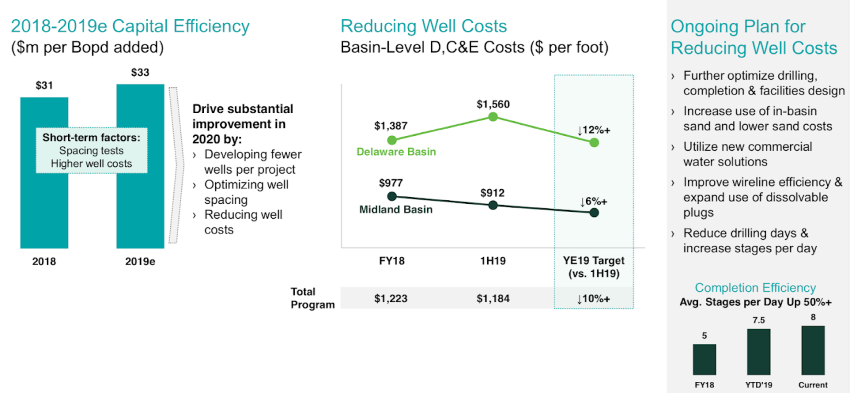

Concho’s spacing tests included the ambitious 23-well Dominator project, which used seven rigs and five frac spreads in a one-mile section. The company first shared results during its second-quarter earnings, saying initial rates were solid but performance data later indicated the Upper Wolfcamp wells were too densely spaced. The wells, which were completed and put on production, were spaced about 50% tighter than Concho’s traditional spacing. The average lateral length was about 4,400 ft.

Taking learnings from the test along with others performed in the Delaware Basin, Concho has made changes to its development program.

“The data generated in these tests will make our development program better,” Leach said during the conference.

In second-half 2019, Concho is planning fewer wells per reservoir and spaced farther apart.

“We’ve plotted our projects with a number of wells for the reservoir on the X-axis and the distance between wells on the Y-axis. The shaded region for 2020 highlights that we’ll increase the distance between wells,” Leach said referencing a chart depicting well spacing changes. “Project size is an important variable. Clearly, Dominator was an outlier. And we’ll develop fewer wells per project on average in 2020, which will improve cycle times and reduce concentration risk. … These efforts are already in motion.”

Leach later pointed out how the rate of return for the project goes down with each additional well drilled. “There is an optimal balance. … We will be moving that balance to higher rate of return next year,” he said.

Note: 2018 Capital efficiency excludes impact of RSP acquisition. Basin-level D,C&E costs are for operated activity and include drilling, completion and wellsite equipment. Completion efficiency reflects CXO’s Northern Delaware Basin and Midland Basin development program. (Source: Concho Resources Inc.)

“As we move back to wider spacing, we expect to continue to generate strong well performance,” he said later in his presentation.

Others have been in positions similar to Concho’s.

Barclays analyst Jeanine Wai said spacing appears to be a “bad penny in E&P these days, but there’s also a lot of different views on the right way to do things.”

Some have reached what they believe is optimal spacing. They, too, are more conservative when it comes to spacing.

Wai brought up the topic while interviewing Pioneer Natural Resources Co.’s CEO, Scott Sheffield, who said the company tested 500-ft spacing in 2014 but saw interference. That prompted Pioneer’s move to 850-ft spacing, which has essentially become the company’s norm in zones in the Permian.

“We’ve seen essentially no interference with that spacing,” Sheffield said.

He added that Pioneer went to wider spacing in the Wolfcamp D only because the company knew it was a thinner zone: a couple hundred feet vs. 300-400 ft for most zones.

“We went to like 1,200-1,300 feet [spacing] on purpose and we’re seeing no interference,” he said. “So, now the question is ‘over time, do we go down to 1,000 or go down to 850?’ I don’t know yet. But we’re really not up-spacing [wider spacing] anywhere [else]. We’re pretty much set on the 850.”

Earlier during his presentation Sheffield said he believes companies, in general, are downspacing because “they are probably running out of inventory.” He added “they’re probably economic wells...but it does affect the parent when you downspace with a child well.”

Mark Papa, CEO Centennial Resource Development Inc., also spoke briefly on well spacing during the conference. Centennial, a Delaware Basin pure-play, also has conservative well spacing.

“In the southern Delaware Basin, we’ve got 880-ft spacing, which is what we’ve had for three years,” said Papa, “and most importantly relative to our Permian peers we’ve had no spacing pattern debacles.”

Recommended Reading

Petrie Partners: A Small Wonder

2024-02-01 - Petrie Partners may not be the biggest or flashiest investment bank on the block, but after over two decades, its executives have been around the block more than most.

Sunoco’s $7B Acquisition of NuStar Evades Further FTC Scrutiny

2024-04-09 - The waiting period under the Hart-Scott-Rodino Antitrust Improvements Act for Sunoco’s pending acquisition of NuStar Energy has expired, bringing the deal one step closer to completion.

NGL Growth Leads Enterprise Product Partners to Strong Fourth Quarter

2024-02-02 - Enterprise Product Partners executives are still waiting to receive final federal approval to go ahead with the company’s Sea Port Terminal Project.

Buffett: ‘No Interest’ in Occidental Takeover, Praises 'Hallelujah!' Shale

2024-02-27 - Berkshire Hathaway’s Warren Buffett added that the U.S. electric power situation is “ominous.”

NOV's AI, Edge Offerings Find Traction—Despite Crowded Field

2024-02-02 - NOV’s CEO Clay Williams is bullish on the company’s digital future, highlighting value-driven adoption of tech by customers.