Floating wind turbines prepare to sail off in 2017 for the world's first floating wind farm Hywind Scotland. (Source: Shutterstock.com)

Towering as tall as the Golden Gate Bridge and as wide as the San Francisco Giants’ baseball field, huge floating wind structures and foundations pose challenges for an industry just getting started on its U.S. journey into deep water, offshore wind experts say.

Imagine not one—like you’d see with an offshore oil development—but possibly 100-plus wind structures transported offshore into water depths of up to 1,000 m or deeper.

Adequate infrastructure to manufacture and assemble components is limited at the moment—nonexistent in some instances.

“The Morro Bay lease area is going to see 300 or so units that will all want to be installed at about the same time. Right now, we have no ability to produce, install or do anything with it,” said Alla Weinstein, founder and CEO of Trident Winds Inc. “This is the challenge that we’re facing.”

Experts gathered for an offshore wind session May 1 at the Offshore Technology Conference (OTC) to discuss challenges offshore wind and solutions face as the U.S. targets 30 gigawatts (GW) of offshore wind capacity by 2030 and 15 GW of floating wind capacity by 2035. Panelists included executives from Trident Wind, Crowley Wind Services and Principle Power, as well as The Business Network for Offshore Wind and the Bureau of Ocean Energy Management.

The U.S. has already begun its floating wind journey, having held in December 2022 its first wind auction for development rights in the Pacific Ocean, where floating wind technology will be used. Five wind leases were awarded in California’s deepwater Morro Bay and Humboldt Bay. More is expected as the U.S. gears up for potential lease auctions offshore Oregon and the Gulf of Maine. The Central Atlantic is also being eyed for floating wind.

Looking at requirements

Unlike conventional fixed-bottom wind turbines attached to the seabed in shallower water, floating turbines are moored to floating structures to harness power in deeper waters. Sitting atop a platform, the turbines are attached with mooring lines connected to the seafloor with anchors. They work the same as other wind turbines: wind pushes the turbine’s blades, causing them to spin and turn the rotor that is connected to a generator.

So far, only 0.1 GW of floating offshore wind has been deployed globally, according to the Biden administration. By contrast, more than 50 GW of fixed-bottom offshore wind has been deployed.

Looking specifically at California, if ports want to play a role, certain requirements must be met, according to Jeffrey Andreini, vice president of Crowley Wind Services. For starters, they must have significant acreage with little to no restrictions, like bridges.

“You can’t have just 10 acres. You probably want to be looking at, at least for floating wind, well over 150 acres to be able to operate,” Andreini said, adding that longevity at terminals are key for anchor tenants.

When it comes to manufacturing, preassembly ports will be needed in southern and central California. “We’re going to need other standby ports. Again, that could be San Diego, that could be L.A. or Long Beach. It could be San Francisco in order to make this whole process work for the U.S. West Coast.

It has been estimated that California will need more than 10 ports to meet the staging, manufacturing and O&M needs of offshore wind. Parallel development required includes tugs and barges, semisubmersible assets, vessels, alternative fuel power and a trained workforce, according to Andreini’s presentation.

Finding solutions

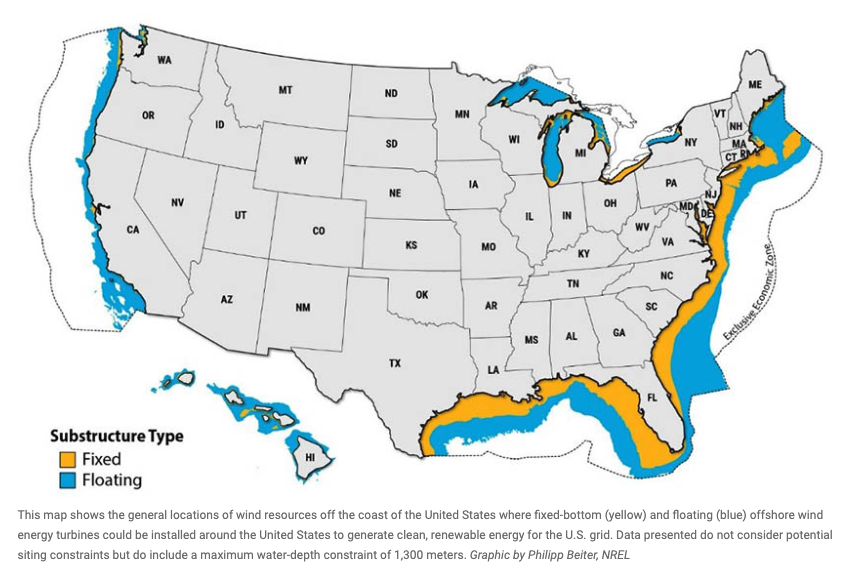

Addressing the challenges matters because most offshore wind energy resources are in deep water both in the U.S. and globally, panelists said.

Weinstein—called an offshore wind power technology pioneer—gave OTC attendees and those involved in advancing floating wind something more to think about in preparation for developments.

These include serial production of floating offshore wind units, given economies of scale matter. If ports are not equipped to handle massive floater turbine components, which call for ample land area and quay reinforcement—among other needs—she added, alternative solutions will be required for final assembly and turbine integration location.

With fixed foundations being uneconomic due to deep water depths, Weinstein wondered if active stations and no moorings could be among the solutions.

Turning to storage and energy conversion, she added, “If we can pair the energy production with energy storage, it could become a baseload supply. It could be energy conversion to hydrogen, to ammonia or whatever.”

Going deeper and sometimes farther for stronger winds also means more umbilical cords, along with added costs, to connect to shore. A different energy delivery method could lead to improvements, she said.

“Can we eliminate the umbilical cord i.e. export cables? Would stored energy at sea eliminate a need for export cables?”

“This is a new industry that we’re all creating and it’s exciting to be a part of that industry, but these are all the things that we can think about,” she said. “Big dreams are great right now. We need to put them in practice.”