The Offshore Technology Conference (OTC) is where energy professionals get the chance to network, exchange ideas and discuss new technologies. The conference gives you access to technical information, an equipment exhibition and professional contacts from around the world.

In 2015, more than 94,700 attendees from 130 countries attended. This year’s attendees will converge May 2-5 in Houston. The following is a sampling of the technologies they will see from some of the top 184 companies exhibiting at the 2016 OTC.

Editor’s note: The copy herein is contributed from companies exhibiting at the 2016 Offshore Technology Conference and does not reflect the opinions of Hart Energy.

Software manages integrity of hull

The industry needs the most accurate data possible to make critical decisions about the future life of offshore assets. The ABS Nautical Systems Hull Manager 3D allows condition data and hull steel thickness measurements to be viewed, tracked and trended, making it easier to understand the condition and manage the integrity of the hull over time. The software converts computer-aided design structural model information into a relational database that captures the condition within a virtual 3-D environment. The combination of web-based Hull Manager and office-based Hull Manager 3D provides a way to see anomalous conditions and critical locations more clearly and to better manage deficiencies to closure. This software offers a way to pragmatically extend the working life of offshore assets. eagle.org/en.html

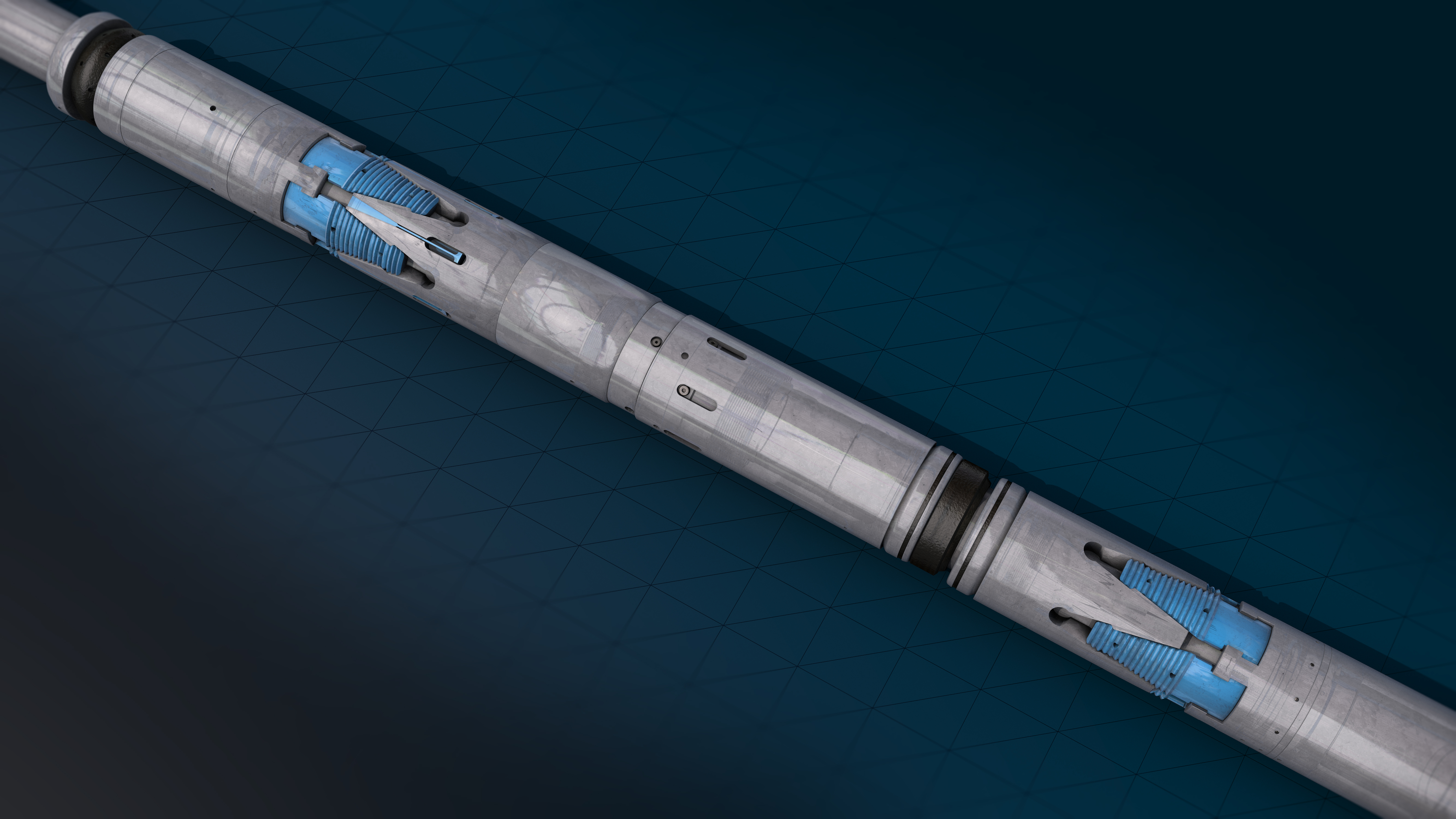

Electrically actuate subsea valves

Aker Solutions’ new permanently installable rotary electrical actuators are part of Aker Solutions EL-drive program, designed to electrically actuate subsea valves for subsea production and processing systems. The low-duty actuator configuration using battery as main source of energy will be showcased at OTC. Measuring less than 85 cm in height, the actuator is easy to integrate, install and qualify for water depths up to 4,000 m (13,123 ft). The actuator consists of a dedicated control system and is based on a series of qualified modular building blocks that makes the control platform easily scalable and configurable both in hardware and software. This gives the ability to customize for specific valves and system architectures. Utilizing the possibilities in the EL-drive program in combination with Aker Solutions flexible Vectus system, the sixth generation of subsea electronic modules, will enable the company to provide control solutions according to specific needs. akersolutions.com

Engineering simulation software helps streamline product development

ANSYS 17.0 is the company’s latest release from its portfolio of software solutions, which are designed to help streamline product development, improve engineering productivity and reduce cost. The increasing use of engineering simulation software is helping oil and gas companies to meet their objectives in developing new equipment, assisting with their vision of the digital oil field and the industrial internet of things, and using computational methods to reduce the cost of physical testing and prototyping. Through virtual prototyping, companies can assess the performance and reliability of equipment in real-life conditions. Applications include subsea factory, flow assurance, emission control, seakeeping, drilling, completion and processing, and wellhead and top side equipment. ansys.com

Alternative to pipeline replacement

APS in conjunction with PETRONAS has developed a subsea pipeline rehabilitation product called InField Liner (IFL), which is inserted into existing (or newly installed) pipelines and basically stops corrosion, extending the pipeline service life with an additional 30 years. IFL is a hydrocarbon subsea pipeline rehabilitation system. It is a flexible Kevlar reinforced liner that can be installed over lengths of up to 5 km (3 miles) in one single pulling operation and can accommodate multiple 90-degree 5-D bends from platform riser to platform riser or from platform to onshore. The liner is highly impermeable, resistant to a wide range of hydrocarbon mixtures (sour crude and gas) with a temperature resistance up to 110 C (230 F). With the IFL system, the offshore industry is offered a viable and economic alternative to pipeline replacement. aps-corporate.com

Removable packer stays removable

Removable production packers can eliminate nonproductive time and reduce costs and risks during well intervention operations. However, these benefits often are negated in deepwater operations when the packer becomes permanently set after being exposed to high pressures and temperatures. The Baker Hughes BASTILLE HP/HT removable production packer uses a new chassis design that lets the packer disengage from the casing when it is released, enabling easy removal. Before being released, HP/HT elastomers maintain a reliable seal between the casing and tubing in conditions up to 204 C (400 F) and 17,500 psi. A slip design increases the contact area four times over that of conventional removable packers to keep the BASTILLE packer anchored while decreasing stress on the casing. When the production tubing is retrieved, the entire packer assembly is retrieved with it, even after years of exposure to HP/HT conditions. bakerhughes.com

Reamer tool eliminates dedicated reamer runs, wiper trips

The Shuriken Reamer ream-while-drilling tool provides a durable and ultraefficient means of reducing nonproductive time and costs associated with typical wellbore problems. Eliminating dedicated reamer runs and wiper trips, increasing ROPs with improved weight on bit, lowering completion times through better wellbore quality and lowering the chances of getting stuck, the cost benefits of using the Shuriken Reamer are comprehensive and substantial. With five patent-pending design features in the cutting structure, cutting elements and blade geometry, this tool is available in a wide range of sizes, in both steel and nonmagnetic materials. The Shuriken Reamer is appropriate for almost any hole size, hole condition, drilling application and formation lithology. bestdiamondbit.com

Flanged-connection fracturing fluid delivery technology

Rigups for fluid delivery in fracturing operations can be highly complex, with multiple flowlines, mismatched equipment risk, and the associated leak paths and HSE risks. Conventional systems, have four to eight lines per well with eight to 14 connections per line and flow restraints mask underlying risk of hammer unions. The Monoline flanged-connection fracturing fluid delivery technology from Cameron, a Schlumberger company, addresses the root issues of hammer unions along multiple pumping lines and eliminates the need for flow restraints. The technology enables faster mobilization and increases fracturing uptime while requiring fewer technicians on location. It simplifies the rigup procedure by arriving on location preassembled and can be installed off of the critical path from the fracturing crew. On the whole, installation time is reduced by more than 60%. By using the Monoline technology instead of fracture iron, one Canadian operator eliminated more than 150 hammer unions and 300 restraints on a nine-well pad, achieving 99% uptime. cameron.slb.com

Coated wireline for pump-down, deviated wireline operations

Camesa, a WireCo WorldGroup brand, has developed a new generation of coated wireline to be used for pump-down and deviated wireline operations. EcoSeal’s smooth surface polymer jacket is designed to withstand high well temperatures and wear on casing/tubing and erosion. It eliminates the need for grease injection and making wellsite operations cleaner and more eco-friendly. Conventional pressure control equipment such as flow tubes and line wipers have been replaced by a specially designed EcoSeal pack-off. It further addresses issues that plague the wireline industry such as cable bird caging, the need for cable seasoning and armor wire stranding. The smooth profile of the cable makes tractoring and pump-down operations more efficient by reducing friction by as much as 40%. Increased running speeds in and out of hole can be accomplished, reducing operational time at the jobsite. wirecoworldgroup.com

Pressurization units provide safer options

Pressurization systems play a key role in the industry’s demand for safety and reliability. Both National Electric Code (NEC) and International Electric Code (IEC) suggest that companies can reduce, limit or eliminate potentially hazardous conditions by adequate positive-pressure ventilation from a source of fresh air coupled with effective safeguards against ventilation failure. Custom Air Products & Services Inc.’s (CAPS) pressurization systems include some key safeguards such as the use of Haz-Loc rated devices as well as area-classified motors and dampers. The use of rated controls allows users to meet area requirements with a smaller footprint providing premium safety options for their most important resource. CAPS will showcase a standalone NFPA 496 version this year at OTC. customairproducts.com

System eliminates gas emissions, reduces environmentally harmful waste

CheckPoint Pumps & Systems has released the Series FXS Solar Injection System, which is optimized for continuous chemical injection and precise flow control. Its Class 1, Division 2 motor ensures a high level of quality and safety, which is met by CheckPoint’s proprietary injection pump. Each system is sized using solar insolation factors to meet customer-specific application parameters, which extends battery and system longevity. This innovative design eliminates gas emissions and reduces environmentally harmful waste often caused by inefficient battery management. The system’s portable design is highly durable but lightweight. A front-access enclosure houses the system’s battery at a height that provides ground clearance. The system-integrated base includes a pump mount and tripod legs, which ensure a stable structural foundation. cppumps.com

Shackle bolt securement system reduces install, release time

The Crosby Easy-Loc V2 shackle bolt securement system makes the process of securing shackles quick and easy—no more threading onto bolts and fumbling with cotter pins. The securement process can even be accomplished one-handedly, in three steps, making it easy for the end user to ensure a secure load under a variety of conditions. The system features a 316 stainless steel design that resists corrosion, and the design reduces potential lifting hazards, such as pinch points and bolt coiling. No cotter pins or tools are required. On average the system is 40% lighter than traditional securement methods. The oversized handle enables easy access no matter the hand size, and the wide-opening grip provides easy access for bolt handling. thecrosbygroup.com

Needle scalers for hazardous environments

CS Unitec’s new line of low-vibration needle scaler kits are ATEX certified for use in hazardous environments. The Trelawny ATEX Vibro-Lo series is designed for all surfaces—metal and masonry—to remove coatings and corrosion and clean other accumulated materials more safely. Models VL203Ex, VL223Ex and VL303Ex are ATEX certified Ex II 2Gc IIA T4 for use where hazardous, flammable or combustible vapors, gases or mists are present and surface temperatures do not exceed 135 C (275 F). This series produces seven times less vibration than traditional needle scalers, reducing operator fatigue, increasing efficiency and helping to prevent injury. Equipped with a dust shroud, these models can be attached to a dust extraction vacuum to reduce hazardous airborne materials. The kit contains nonsparking Copper Beryllium needles and a fall arrestor to eliminate the risk of dropping the tool. csunitec.com

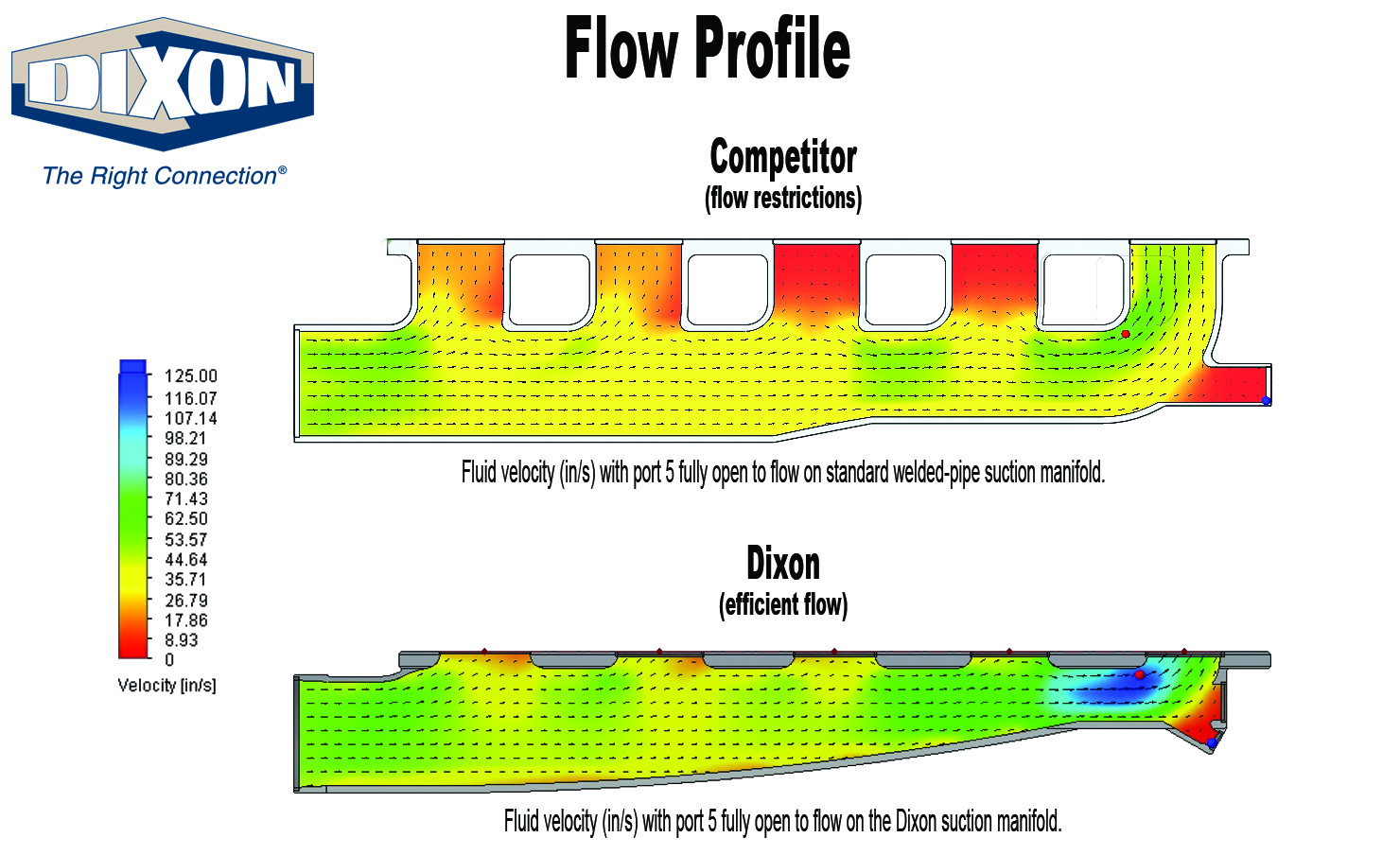

Suction manifolds increase flow, eliminate leak-prone weld seams

Dixon Valve & Coupling Co. recently has focused on evolving geology and directional drilling technologies including an innovative one-piece suction manifold that feeds slurry into high-pressure pumps. The manifold design was the result of hydraulic fracturing companies experiencing pump cavitation due to proppant dropout, which causes destructive flow restrictions. The Dixon design combines unique flow geometry with one-piece iron manufacturing technology to increase flow and eliminate seven to 18 leak-prone weld seams. The 3-Port and 5-Port suction manifolds are patented for use with high-horsepower pumps and have been laboratory and field tested. The flow profile simulation demonstrates the differences between the standard welded pipe and the Dixon manifolds. dixonvalve.com/splash

Jet cutters create a clean cut the first time

DynaBlade jet cutters from DynaEnergetics create a predictive and clean cut the first time on every run. This saves rig time and lowers the risk during workover, stuck pipe or tubing/casing recovery operations. These third-generation technology jet cutters reduce flare to a minimum and avoid damage to outer casing strings. The cutting depth can be accurately predicted when pipe specifications, downhole temperature and hydrostatic pressure are known. For extreme conditions, custom sizes can be built and tested to 35,000-psi working pressure. DynaBlade jet cutters reliably sever lined, plastic-coated and corroded/scaled pipe and perform across a wide range of downhole well conditions. Anchoring is not required so there is minimal risk of sticking. The DynaBlade portfolio includes more than 70 sizes covering coiled tubing, drillpipe, production tubing, packer mandrel and casing cutting applications. dynaenergetics.com

First clamped enclosure design for hazardous environments

Power management company Eaton developed the first clamping enclosure technology for hazardous areas to help enhance safety and improve productivity. Eaton’s Crouse-Hinds series EBMX technology helps customers avoid unbolting enclosures to access internal motor control components for installation, maintenance or troubleshooting. The Eaton technology is the first National Electrical Manufacturers Association 7 classified enclosure to use clamping technology. The clamped enclosures are designed to automatically apply even pressure across the flame path and enhance safety by reducing installation errors and avoiding missing or improperly torqued bolts. eaton.com

Offshore containers for rigs, platforms, vessels

ELA Container Offshore GmbH produces standalone offshore containers for rigs, converter platforms and all types of seagoing vessels, pontoons and barges. These 6-m (20-ft) offshore containers are provided as living quarters, offices, mess rooms, galleys, laundry facilities, recreation or locker rooms for individual demands. Due to the 6-m International Organization for Standardization Norm measurements with the Convention for Safe Container (CSC) approval and the tare weight of only 7.7 tones, the handling of containers is easy. All units can be stacked up to four high to save even more space. With stairways and gangway containers, a complete accommodation facility can be configured, planned and assembled onsite. All containers are DNV2.7-1 /EN 12079-1, CSC certified. In terms of fire resistance, an A60 insulation provides high safety standards. At OTC 2016, ELA Container Offshore GmbH is showcasing the ELA offshore accommodation complex, including two ELA offshore living quarters, differently equipped and the ELA offshore office. ela-offshore.com/en

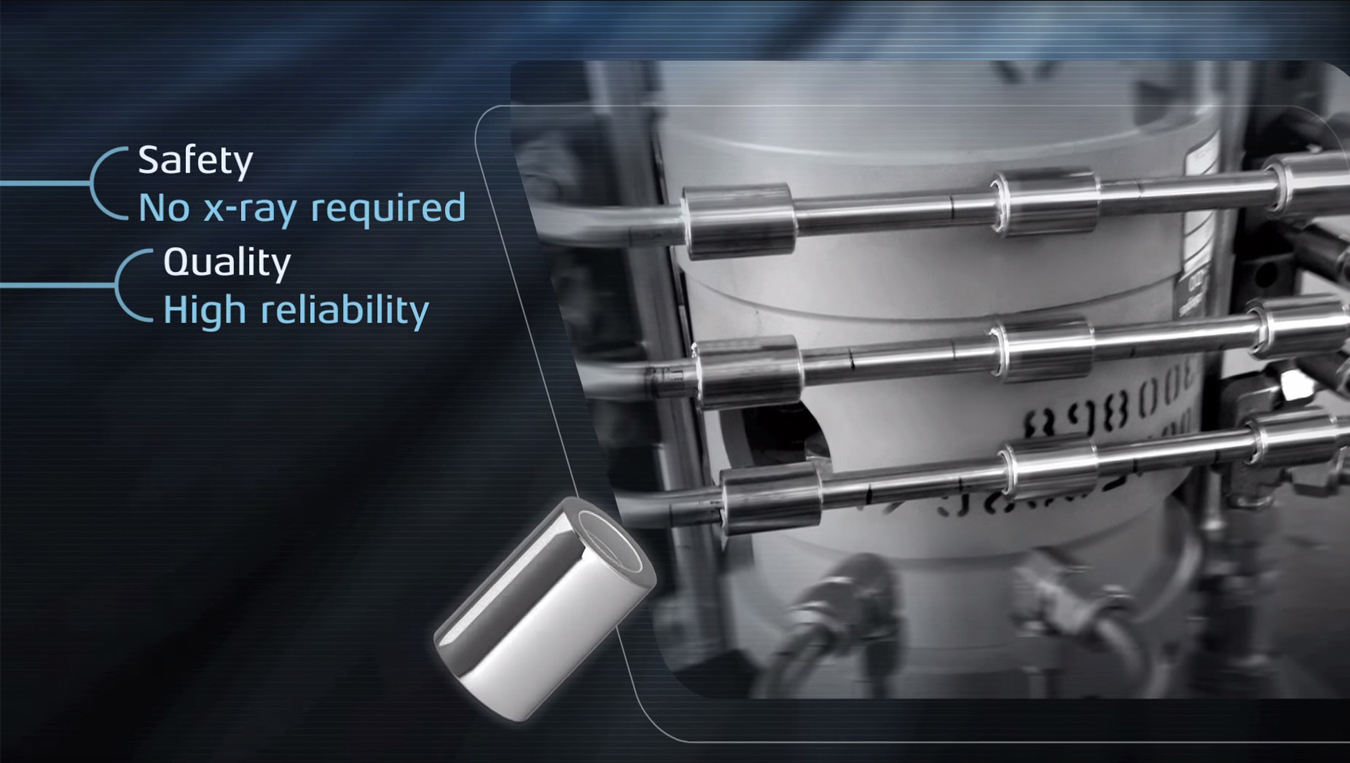

Subsea fittings replace orbital welding

FMC Technologies has developed and patented a technology to replace the orbital welding process used to connect small bore hydraulic tubing in subsea equipment—the Shape Memory Alloy Subsea Fitting. The technology is based on a Shape Memory Alloy—a nickel-titanium material that returns to its original shape after subjected to environmental changes such as temperature or pressure. Shape Memory Alloy connections require only one-third of the cost of welded connections and can be installed in 30 seconds, simplifying and speeding up assembly and inspection times. The technology also is safer for personnel since X-ray inspection is no longer needed. The technology development was done in partnership with Shell Brazil and earned a Spotlight on New Technology award at OTC Brazil 2015. fmctechnologies.com

Connectors can handle extreme tension

Most familiar for its tubular running services, Frank’s International also provides well completion, intervention and recovery equipment and service offerings. At this year’s OTC, attendees can explore technology advances that include Frank’s new Xtreme3 Premium Connectors, which are designed to handle extreme tension, compression and bending requirements. Attendees can learn about new remote tong systems that provide electronically preset torque and speed and eliminate need for a hydraulic power unit. Frank’s International also is showcasing new casing running tools, deepwater completion running solutions and other drilling technology offerings. franksinternational.com

Life-cycle management system for critical flexible hose assemblies

The technology powering today’s drilling rigs and oilfield equipment is increasingly complex and can include up to 10,000 flexible hose assemblies transporting everything from fuel, hydraulic oil and drilling fluid to a multitude of hazardous chemicals. GATES Hose Management System is a comprehensive life-cycle management system for critical flexible hose assemblies (FHA) that allows traceability and compliance, reducing downtime and incidents due to FHA failures. The Sentry tag and track module helps rig managers stay in compliance, with a simple scan of the RF-ID tag on any hose. The product provides instant access on how long that hose has been in service and alerts users when it’s almost time to replace it. The Sentry DAT module, a data analysis tool, helps operators make smarter decisions by providing immediate visibility to cost, performance and efficiency data for every hose asset on the rig. gates.com

Nitrogen membrane technology for marine industry

The GENERON membrane is a solubility- and diffusivity-driven process directly proportional to the partial pressure differences of components in the feed and permeate gas streams. A GENERON membrane module contains millions of single hollow fibers that act as a molecular filter. When high-pressure gas mixtures enter the separator, the gas components divide as a result of selective permeation. Fast gases such as oxygen permeate easily through the membrane wall and exit the side port. Slow gases such as nitrogen have a difficult time passing through the membrane wall and travel the bore of the fiber exiting through the port at the end of the shell. If the feed gas is supplied to the membranes with pressures greater than 500 psig, then a different flow scheme is used. In high-pressure applications, like CO₂ removal from natural gas, the membranes are supplied with the feed gas on the shell side of the hollow fibers, and the permeate gas containing the “faster” gases are collected inside the bore of the membrane fibers. generon.com

Technologies help reduce uncertainty

Halliburton’s SmartPlex downhole control system is designed to improve reservoir performance and reduce operator costs related to installation and control of multiple zones. It activates valves significantly faster than competing direct hydraulic control systems and offers the ability to selectively open and close different sets of valves, helping to reduce uncertainty and allowing for multizone completions with increased reliability. In addition, Halliburton’s BaraLogix density and rheology unit is a combination of density and rheology measurement capabilities in a single, modular package. Automating routine fluid property tests provides access to more precise and dependable drilling fluids properties in real-time data that is vital when crucial decisions are required. This helps enable fluid technicians to focus on more critical rig-site responsibilities and take a more proactive approach to managing drilling operations. The frequency and accuracy of the data can help operators in predicting potential problems or detecting issues that require faster response times. This can help reduce or eliminate nonproductive time and provide substantial cost-savings potential to any offshore project. halliburton.com

Cable technologies for the offshore energy industry

JDR will showcase its range of technologies for the offshore energy industry at OTC. The showcase will feature its Intervention Workover Control Systems umbilicals, a full range of subsea production umbilicals including steel tube umbilicals, and subsea power cables, which JDR supplies globally. In addition, JDR will display its inter-array cables for offshore renewables. The company offers a full range of cable technologies. The company provides local solutions as well as FEED and analysis services from its global service centers. jdrglobal.com

Motion, vibration control products for harsh areas

LORD Corp. experts can help increase the value and durability of products in challenging downhole and offshore environments. With more than eight decades of experience in industrial and aerospace sectors, the company provides motion and vibration control solutions. LORD’s products include downhole shock and vibration attenuation tools that increase the reliability of MWD electronics, surface equipment mounts, sensing solutions, and offshore flexible joints, packers and elastomeric bearings. LORD.com/OilandGas

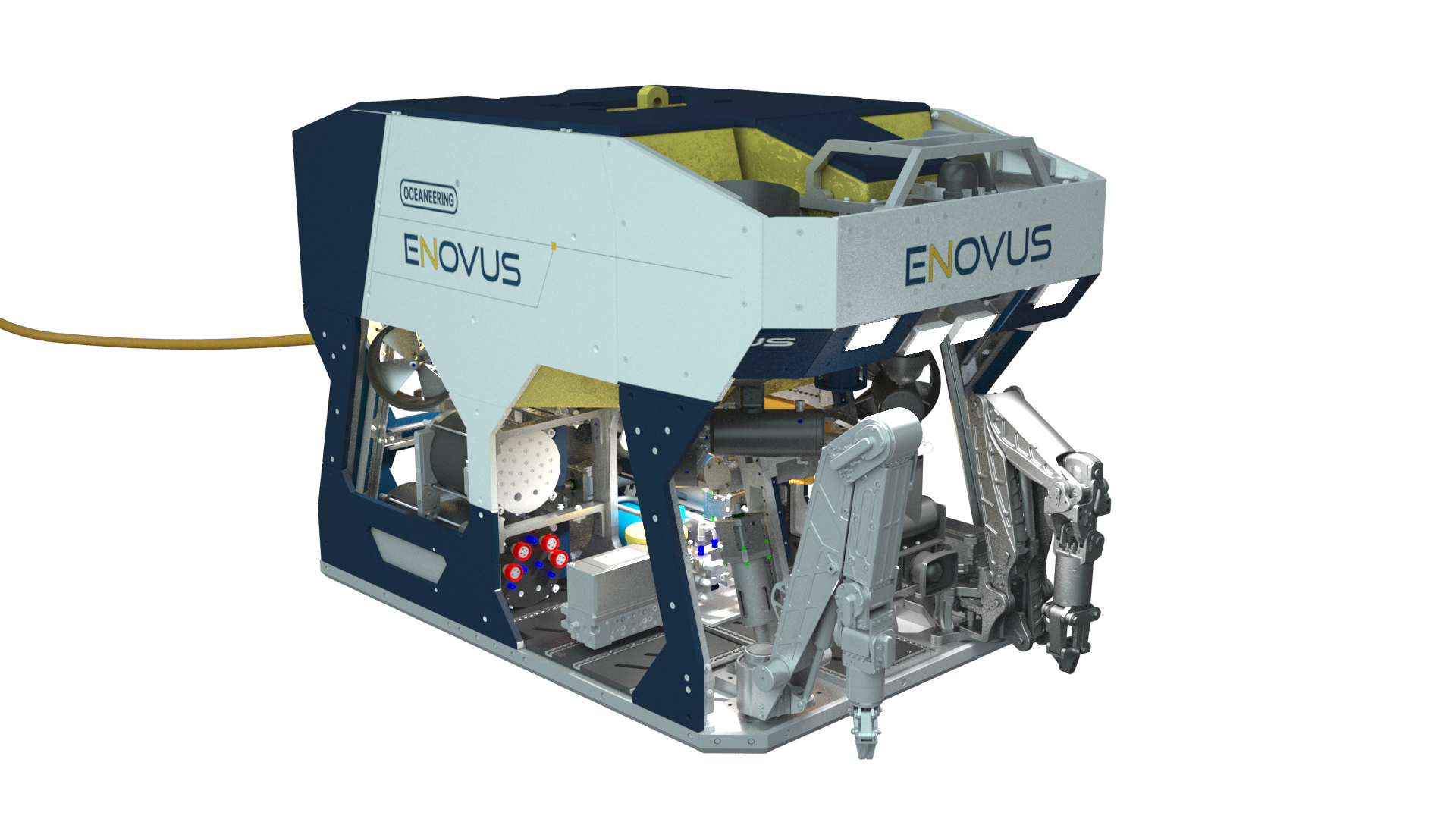

ROV enhances user interface, reliability to perform subsea tasks

Oceaneering will showcase its newly advanced and environmentally friendly ROV, the eNovus, at OTC. The eNovus will serve as the basis for a future hybrid between AUVs and ROVs. With remote piloting and automated control technology, the eNovus enhances user interface and reliability to perform common and complex subsea tasks. The vehicle has a modular, noncorrosive chassis allowing ease of tooling integration and is designed to withstand extended periods of time subsea with little to no maintenance required. Powered by a 172kVA fully electric propulsion system, the eNovus offers all electric tooling options via an electric tooling control unit, manipulator tool changer and all electric tooling suite. With supervisory control, the eNovus supplements and enhances pilot skills by using vision control software to function the ROV’s manipulators and thrusters. This electro-hydraulic tooling flexibility is designed to maximize and transform available power, efficiency and configurability of this vehicle. oceaneering.com

Technology demos at OTC

OneSubsea, a Schlumberger company, will provide live demonstrations of two new technologies at OTC that are designed to help reduce costs while enabling operational improvements. The HyFleX subsea tree system reduces capex and opex through a design using field-proven components. Providing benefits of both vertical and horizontal conventional trees without the usual compromises, this OTC Spotlight on New Technology winner can provide significant cost savings in field development and over the life of the field. The AquaWatcher water analysis sensor, also an OTC Spotlight on New Technology winner, has the capability to detect minuscule quantities of water in multiphase and wet gas flows, and determine the salinity of that water. It also can determine the ratio of injected chemicals to water. In addition, OneSubsea will feature a multiphase subsea pump and a PhaseWatcher Subsea Multiphase Flow Meter with Vx Technology in its OTC booth. onesubsea.com

Reliable power for offshore operators

Perkins Pacific, a master distributor for Perkins engines in the Western U.S., will showcase 400 Series and 1200 Series engines at OTC. These highly reliable engines help onshore and offshore equipment operate at peak performance in tough conditions. Perkins engines can increase efficiency and lower operating costs for generators, hydraulic pumps, water pumps and waste pumps. On display will be a 1200 Series engine, designed for optimized fuel consumption and developed with hundreds of variables to fit easily into equipment, and the new compact Perkins 404F-E22TA engine with common rail direct injection and full authority electronics. perkinspacific.com

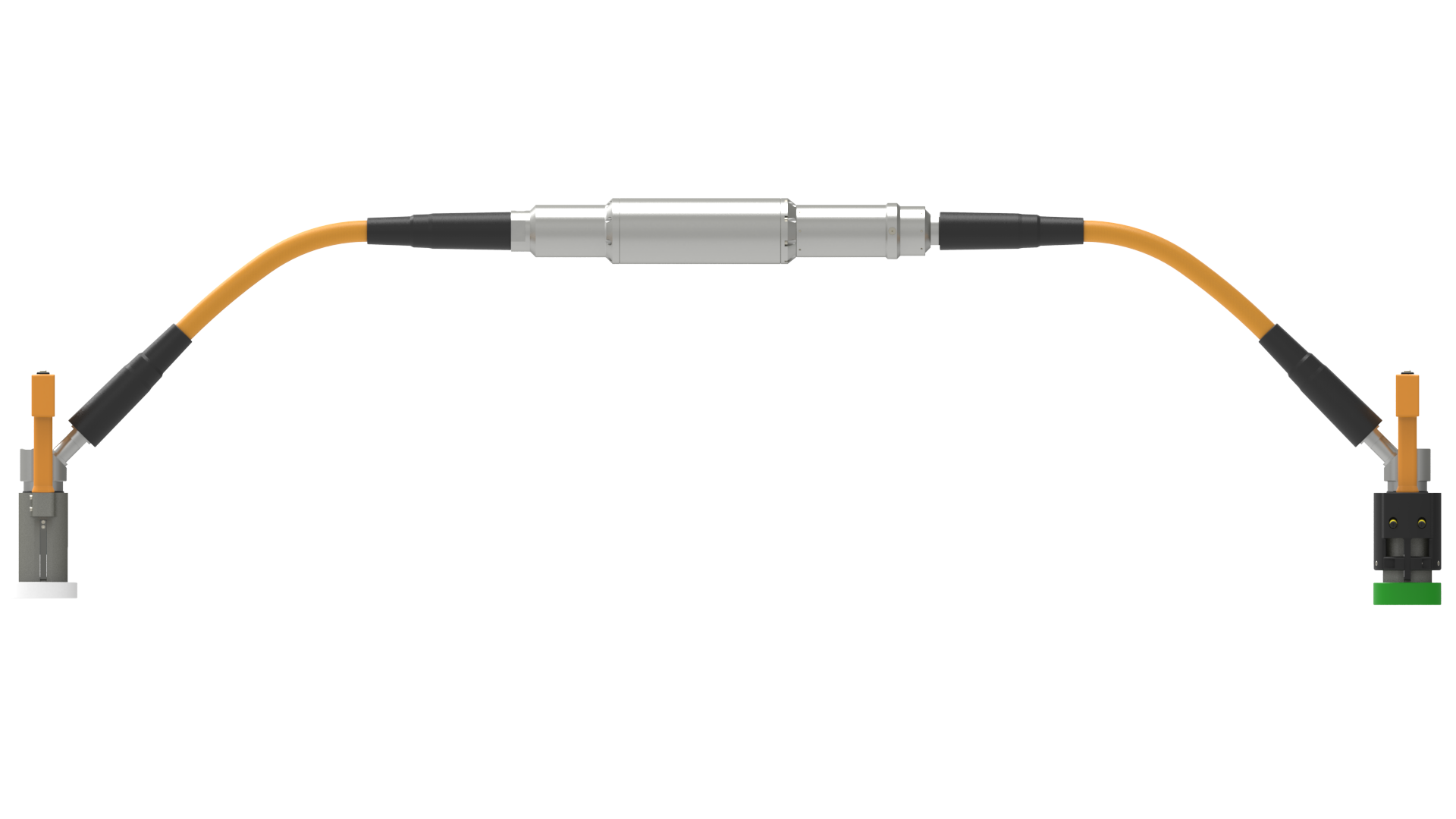

Flying leads simplify field layouts, upgrade brownfields

Typical subsea flying leads, or jumper assemblies, are passive components in subsea fields that transmit power or data from point to point. New technology from Teledyne Oil & Gas has transformed the flying lead into an adaptable platform that can extend step-out lengths, convert power or media, or add other project-specific functions within the jumper assembly itself. The Active Flying Leads (AFL) product line will allow oil and gas operators to simplify field layouts, upgrade brownfields with newer technology and accomplish greater levels of equipment compatibility. The AFL platform consists of functional electronics housed within a qualified atmospheric chamber that can be integrated into a pressure-balanced, oil-filled hose. Teledyne DGO’s glass-to-metal sealed penetrators provide fail-safe pressure barriers within the chamber for reliable performance under the extreme pressures found in deepwater subsea fields. teledyneoilandgas.com

Subsea vibration suppression system

Trelleborg’s offshore operation’s new Tri-Strake Combi is a vortex-induced vibration (VIV) suppression system. Pipelines unsupported over free spans, such as steel catenary risers and rigid steel flowlines, are prone to VIV fatigue, which can lead to serious issues such as pipe girth weld failure or premature pipe malfunction. To combat this, Tri-Strake Combi comprises interlocking moldings, with three-start helical strakes. The system’s lightweight construction provides operators with a simple and rapid assembly method. The customized high-endurance material selected for the system provides added resilience and load-bearing capacity, and eases installation. Each section of the system is designed as a lightweight hinged component, ensuring quick and easy preinstallation onshore or installed offshore. The modular design enables the system to be stacked during shipping, ensuring more efficient and cost-effective transportation. trelleborg.com/offshore

System offers vibration, shock resistance

WAGO provides onshore and offshore products for drilling, processing and marine equipment production. Input/output (I/O) system solutions include hazardous location I/O, modules with integrated intrinsically safe barriers and fieldbus independent gateways. Most modules carry worldwide hazardous location certification and global marine ratings. Product highlights include the 750 XTR system. Available in multiple module offerings and providing users with the flexibility to design automation for harsh environments, the 750 XTR Series offers reliability in extreme temperatures, vibration and shock resistance, and protection against electromagnetic compatibility interference. In addition, WAGO offers process-ready terminal blocks, power supplies and connectors that are built for corrosive, thermal cycling and vibration-prone applications. wago.us

Wellhead design reduces time, labor and risk

Weir, which provides technologies and services to upstream global markets, will showcase the Seaboard streamlined wellhead design at OTC this year. The system is engineered to reduce the amount of time, labor, cost and exposure to risk associated with the assembly of casing and attachment to the BOP beneath the platform. Featuring a mandrel casing hanger and a quick-connect stabilizing hub, the system allows operators to run preassembled casing for stages one and two through the wellhead with no flame cutting, welding or grinding required. It also eliminates the need to remove and reattach the BOP, along with the need to set lockscrews. By limiting the amount of time and labor personnel spend below deck, where the space is confined and dangerous, the process saves money and mitigates risk. global.weir

Recommended Reading

Sangomar FPSO Arrives Offshore Senegal

2024-02-13 - Woodside’s Sangomar Field on track to start production in mid-2024.

CNOOC Makes 100 MMton Oilfield Discovery in Bohai Sea

2024-03-18 - CNOOC said the Qinhuangdao 27-3 oilfield has been tested to produce approximately 742 bbl/d of oil from a single well.

CNOOC Finds Light Crude at Kaiping South Field

2024-03-07 - The deepwater Kaiping South Field in the South China Sea holds at least 100 MMtons of oil equivalent.

Equinor Receives Significant Discovery License from C-NLOPB

2024-02-02 - C-NLOPB estimates recoverable reserves from Equinor’s Cambriol discovery at 340 MMbbl.

US Raises Crude Production Growth Forecast for 2024

2024-03-12 - U.S. crude oil production will rise by 260,000 bbl/d to 13.19 MMbbl/d this year, the EIA said in its Short-Term Energy Outlook.