New technology remains key to unlocking the oil and gas resources being pursued by operators in both conventional and unconventional reservoirs around the world.

In this special section E&P has highlighted some of the latest products and technologies to be shown at the SPE Annual Technical Conference and Exhibition (ATCE) in Houston and looks at how they will benefit companies in their ongoing operations to find and produce new reserves.

SPE ATCE’s opening general session this year will focus on meeting the long-term energy challenge to 2040 within the current industry environment of costcutting and deferred projects. This means less investment in the very oil and gas developments that will be required to produce new reserves and meet forecast demand, which is expected to see oil consumption grow by 32% by 2040 from today’s level. This growth, combined with the increasing use of natural gas, means that oil and gas together will constitute more than 60% of the global energy mix by 2040.

As a result, the importance of new and improved technologies and products that can enable projects to be commercialized or existing producing assets to be enhanced has never been more apparent.

With more than 450 exhibitors participating in SPE ATCE, there are many innovative products and solutions to be found on the show floor as well as in the technical sessions and workshops, which will touch on subjects ranging from gas scrubbers and flow assurance challenges to new completion technologies and EOR techniques.

The copy herein is contributed from service companies and does not reflect the opinions of Hart Energy.

Cement evaluation service provides data about cement properties

The Baker Hughes Integrity eXplorer cement evaluation service allows a change for the evaluation of the cement integrity of oil and gas wells. This new technology applies electromagnetic-acoustic sensors in cement evaluation and allows operators to directly assess the integrity of cement bonds in any current wellbore environment or cement mixture. While cement compressive strength has typically been used as a key indicator of cement quality, today’s challenging environments require a more detailed assessment. The Integrity eXplorer service provides operators with accurate and comprehensive data about the properties of the respective cement, which enables them to make critical decisions to help protect their assets, reduce nonproductive time and minimize unnecessary remediation. The Integrity eXplorer service will be featured in the Baker Hughes booth 2125 at ATCE. bakerhughes.com

VSD will be first in North America to power both induction motors, PMMs

Borets will be showcasing its permanent magnet motors (PMM), WR2 pumping system, PMM progressive cavity pump (PCP) and Axiom II variable-speed drive (VSD). The PMM is used in downhole electric submersible pump (ESP) systems. Power consumption is 10% to 25% better than that of induction motors, lowering energy costs and reducing the carbon footprint of these systems. The motor also is 40% shorter and lighter than induction motors and has a higher power factor and power density. This system will save about 15% on immediate power costs, and its cooler operating design should improve system runlife. The WR2 pumping system offers a new and different way of manufacturing downhole ESP systems. Suitable for unconventional horizontal wells, the WR2 can produce sand and gas in greater quantities than previously possible in the ESP industry. The PMM PCP is a new downhole-driven PCP system that does not use a gear box like current technology. This provides a step change in the operations of PCPs in deviated wells. Borets has about 400 systems in place today and is just bringing PMM PCP to the North America marketplace. The Axiom II is a new VSD made to seamlessly drive both induction motors and PMMs. The drive will be the first in North America to power both types of motors as well as introduce new safety features and custom software to extend ESP runlife. borets.com

Digital knowledge system compares assets against proven analogs

The Digital Analogs Knowledge System (DAKS) is a knowledge platform with detailed field and reservoir reports, a comprehensive geologic and reservoir engineering database on the world’s most important fields and reservoirs, and a platform for reservoir performance analysis. C&C Reservoirs DAKS allows companies to improve exploration success, optimize field development plans, enhance production performance and maximize the recovery efficiency of their E&P assets through application of lessons learned and best practices drawn from nearly 1,500 rigorously documented fields and reservoirs. Benchmarking and analytical tools, along with the ability to capture knowledge about clients’ own assets for comparison against proven analogs in DAKS, enable them to make better E&P decisions. Parameters, attributes and ideas from proven fields and reservoirs can be used to verify E&P hypotheses and boost E&P decision-making confidence. ccreservoirs.com

Using DAKS for this client field, a number of potential technical issues were identified when compared to global analogs. Parameters that are less than P10 for the analogs are highlighted in yellow, and parameters that are greater than P90 are highlighted in red. This information, along with other details on the analogs, can be used to identify programs that might improve development of the field and increase the recovery factor. (Source: C&C Reservoirs)

Fracturing fluid system requires fewer chemicals

The CalVisc fracturing fluid system was introduced in the Williston Basin in 2014. Developed as an alternative to traditional crosslinked fluid systems, CalVisc provides many completion advantages. The fluid has a shear thinning characteristic, resulting in greater viscosities at low shear rates. With these loadings, the fracturing fluid system allows fracture treatments to be placed in numerous wells using the same sand design previously used with crosslink guar systems. In addition, CalVisc requires fewer chemicals, resulting in improved economics when compared to similar completion designs. Lower chemical volumes also mean fewer pieces of equipment needed to perform a fracture treatment and, to date, the higher concentrations of friction reducer have not presented any operational issues. Trial wells have shown no increased difficulty in fracture placement and have demonstrated an average 25% increase in 90-day oil production numbers. calfrac.com

Ultraconductive high-density ceramic proppant designed for harsh environments

The CARBO precision-engineered KRYPTOSPHERE HD ultraconductive, high-density ceramic proppant is designed to enhance production in harsh environments. One of the industry’s strongest proppants, KRYPTOSPHERE HD will be featured along with the CARBO technology platform trio of production assurance, flow enhancement and fracture evaluation services. KYPTOSPHERE HD is engineered with unsurpassed conductivity, compressive strength and durability, with uniform pore throats to enhance flow. The uniquely engineered technology also withstands the extreme cyclicloading conditions of

high-flow wells. KRYPTOSPHERE HD can be used as a base proppant for the CARBO technology platforms, as reflected in the Gulf of Mexico’s Lower Tertiary where it was applied successfully and conjointly with SCALEGUARD proppant-delivered scale-inhibition technology. With this evolving technology, chemical inhibitors for scale and other barriers to optimize flow are infused into the proppant, allowing an engineered release of inhibitor for long-term and cost-effective treatment. carboceramics.com

Mechanical gel strength apparatus measures phase changes of oil well cement slurries

Chandler Engineering, a leader in drilling and completion instrumentation, introduced the Model 5265MG Mechanical Gel Strength Analyzer for direct measurement of gel strength development of oil well cement slurries. This technology allows oil service companies and operators to accurately determine the potential for gas and fluid migration between the casing and formations. The Model 5265MG provides an accurate simulation of the entire cementing process including the dynamic slurry conditioning and placement phase as well as the static gel phase of the operation. The design includes a precision step motor and reaction force transducer, which allows the instrument to efficiently and precisely measure phase changes. The sealed step motor is capable of effective measurements as low as 0.2 degrees per minute for the gel phase and up to 150 rpm for slurry conditioning. The maximum temperature is 204 C (400 F), and the maximum pressure is 20,000 psi. For more information, visit Chandler at booth 3417 at SPE or go to chandlereng.com.

Reservoir modeling workflow delivers understanding of field-scale operations

Computer Modelling Group’s (CMG’s) reservoir simulation software is recognized worldwide as the standard for simulating the unconventional, including hydraulic fractures, thermal, EOR, compositional and advanced recovery processes as well as conventional black-oil reservoirs. Durng SPE ATCE, CMG will host several presentations highlighting its chemical EOR, thermal and brownfield reservoir modeling capabilities, including talks on its workflow for modeling complex shale and tight oil or gas reservoirs. The workflow uses CMG simulators with Builder’s user-friendly wizards to model naturally or hydraulically fractured reservoirs to analyze and forecast multiwell, multipad models. CMOST quantifies uncertainty to manage risk and identify opportunities while also optimizing well and fracture spacing to increase production, net present value (NPV) and EUR. Applying CMG’s unconventional reservoir modeling workflow can deliver a better understanding of field-scale operations and can reduce costs while maximizing NPV. Visit CMG at booth 1925 to learn more. cmgl.ca

Suite of interpretations offers abundant analysis resources

Digital Formation offers petrophysical analysis software and services covering a wide variety of interpretations. In addition to standard shale formation analysis, the company has developed specific solutions that include relative and effective permeabilities to water and hydrocarbon as continuous curves; fracture identification from standard triple and quad combo logging suites; rock physics modeling, including distinction between brittle and ductile rock; and specialized analysis of unconventional shale reservoirs. The suite of interpretations offered will quantify a variety of reservoir components, including net pay for both clean and shale formations; recognition of fracture intensity for both open and cemented fractures; correlation to seismic attributes integrating well data with seismic records; definition of brittle vs. ductile intervals as input to stimulation design; identification of levels of likely high water production; and images (brittle and ductile, or fractures). digitalformation.com

Petroleum planning software connects asset teams, corporate planners, operational teams

Enersight will be at SPE ATCE at booth 4012 demonstrating its petroleum planning software, a comprehensive, integrated planning software that can connect asset teams, corporate planners and operational teams for continuous, unified decisions. Production forecasting, economic modeling, resource scheduling and corporate budgeting are all integrated in Enersight so multidisciplinary teams can intelligently plan, track and manage their assets. The company will demonstrate how to run scenarios quicker and easier, with side-by-side comparisons to evaluate options. Enersight software also incorporates operations activity scheduling that factors in true production constraints of development decisions plus capital forecasting. This integrated, holistic approach to field development and corporate planning helps upstream petroleum producers make competitive and cost-effective decisions at every stage of their business, achieve stronger rates of return, demonstrate capital efficiency, optimize production and replace reserves. enersight.com

Expandable liner offers predictability of planed fracture stages

The limitations of chemical diverters and existing methodologies led Enventure to develop the ESeal Refrac (RF) solid expandable liner. The ESeal RF liner provides a new wellbore with zonal isolation of existing perforations and internal pressure integrity that enables greater predictability of planned fracture stages. This translates into a faster payback on investment and extended production life of the reservoir. Typically, various mechanical and chemical refracturing techniques have been employed, with widely mixed results. For one, sealing off older, unproductive perforations with particulates is unpredictable, unreliable and usually requires multiple attempts. Even then, sustained integrity remains a giant question mark. Chemical diverting agents, while popular, lack internal pressure integrity and tend to go the path of least resistance. Case studies are available to the public at Enventure’s technical library at enventuregt.com/en/technical-library.

Surface seismic monitoring system enables low-noise detection of seismic event magnitudes

ESG’s surface seismic monitoring system is a digital microseismic recorder. Intended for harsh outdoor conditions, the system monitors seismic events from the surface during hydraulic fracturing. The surface system enables accurate and low-noise detection of a wide range of seismic event magnitudes and is ideal for detecting induced seismicity. Combined with ESG’s downhole array system, the surface system ensures the most accurate and robust detection of seismic events, giving a highly detailed view of the hydraulic fracturing program. The surface system also has a small footprint and has been designed within a durable, flexible and customizable platform. ESG understands the importance of having up-to-the-second access to microseismic data to monitor a hydraulic fracture, and the surface system is web-enabled so streaming data are accessible from anywhere in the world. esgsolutions.com

Proppant transport technology can reduce cost per barrel of oil equivalent

Propel SSP proppant transport technology is reducing the cost per barrel of oil equivalent by increasing hydraulic fracturing efficiency. This proppant and fluid system in one, typically, can increase hydrocarbon production by more than 30% within six months and, in some cases, more than 50%. The technology is a hydrogel polymer wrapped around a proppant that swells when mixed with water, reducing the proppant’s effec-tive specific gravity. The proppant, which resists settling, stacks higher for a longer effective fracture half-length. Once at bottomhole conditions, a breaker unwraps the polymer from the proppant; the polymer and water become a low molecular-weight fluid that flows back easily. Unlike traditional fluid systems, damaging residue that can choke off valuable production does not remain in the fractures or around the proppant pack. Propel SSP technology enables greater production by traveling farther in a thin fluid for better propped fracture area and conductivity. fairmountsantrol.com

Gas extractor for real-time wellsite analysis designed to eliminate inconsistent readings

Gas Cannibal, from Fluid Inclusion Technologies (FIT), is a constant volume pneumatic gas extractor for real-time wellsite analysis that is designed to eliminate inconsistent readings.

Features include:

• Auto-leveling to mud level changes before they adversely affect observed sample gas chemistries;

• Fully automated for unmanned 24/7 operation;

• Universal design for use with any wellsite gas analyzer and flow system;

• Rugged construction, including sealed bearings, an explosion-proof motor and a stainless steel design;

• Modular design for quick changeout and sealed components, allowing safe wash-down of the unit;

• Wide range of height adjustment with a usable range of 19 in.; and

• Small footprint, allowing the unit to fit in an 8-in.-diameter opening in the header tank.

For additional information about the Gas Cannibal or any other FIT service, visit booth 3043. fittulsa.com

Mixed flow stage pump capable of handling gas, abrasive content

Unconventional wells usually have a very fast decline curve. IP rates start high and then decline rapidly within the first few weeks or months. The wells usually have about a 50% oil-water ratio, and the wells are high in gas content and have high abrasive (sand) content. These pumping conditions can be very challenging to an electric submersible pump (ESP) and can cause gas locking, cyclic operation, reduced run time, reduced oil production and higher operating expense. GE recently introduced the first-ever mixed flow stage pump in its TD 675 Pump that is capable of handling both gas and abrasive content better than radial flow stage designs. The new Q Plus design is an ESP with tungsten carbide bearings not only for down thrust and radial support but also for upthrust support. This means a true wider operating range that will stay in the well longer, allowing customers to maximize oil production and minimize lifting costs. geoilandgas.com

Technology provides detailed, targeted geologic information

Seismic on Demand is a new product offering that integrates 3-D and ambient seismic via acquisition design and processing techniques to deliver high-resolution seismic at a scale and pace that are practical for pad-based operations. Global’s Seismic on Demand provides detailed and targeted geologic information of the planned production area. The flexibility of the AutoSeis recording system, coupled with its 3-D design, makes acquisition fast—days in the field rather than months—and leaves minimal environmental impact for easier permitting. Processing of high-resolution 3-D and ambient seismic data maximizes understanding of faults, fractures and stress fields. Seismic on Demand can reduce environmental impact, cut costs and increase efficiency without compromising data quality. It also meets the growing need for data that support detailed well planning and completion design. globalgeophysical.com

Latest software version supports competency management needs

In October 2014, IHRDC, which specializes in oil and gas training, worked in collaboration with SPE to launch the SPE Competency Management Tool (CMT) for its worldwide membership. This year, IHRDC and SPE will be expanding the reach of the tool’s initial launch with CMT 2.0. CMT 2.0 will include an expanded list of competency models and is built on IHRDC’s new competency management software platform, CMS Online 4.1,which is set to be released in September 2015. CMS Online supports its clients’ competency management, talent management, and employee and organizational development. The new version will have a new look and a more powerful capability to handle companies’ competency management needs. CMS Online assists companies in complying with internal and external requirements for compliance training and competency management and also enables clients to follow the process requirements of third-party accreditation bodies, such as OPITO, for evidence capture and assessment methods. ihrdc.com

BVS sends pressure readings, records for multiple days

Interwell’s wireless barrier verification system (BVS) was developed to meet the demand for barrier plug integrity assurance. The BVS transmitter is configured to send pressure readings but also can record for multiple days depending on battery configuration, wellbore temperature and logging frequency. The receiver also records and stores the pressure information collected above the installed plug for reference and wirelessly receives the values from below the barrier plug. The BVS provides information to determine the overall quality of the barrier installed, allowing operators to obtain a positive verification of well barrier and integrity with a higher degree of confidence. With the supply of downhole data from mechanical wireline operations available online and even in real time, the BVS can save operational time with a more efficient verification of the barrier, especially in low-pressure wells with free gas. interwell.com

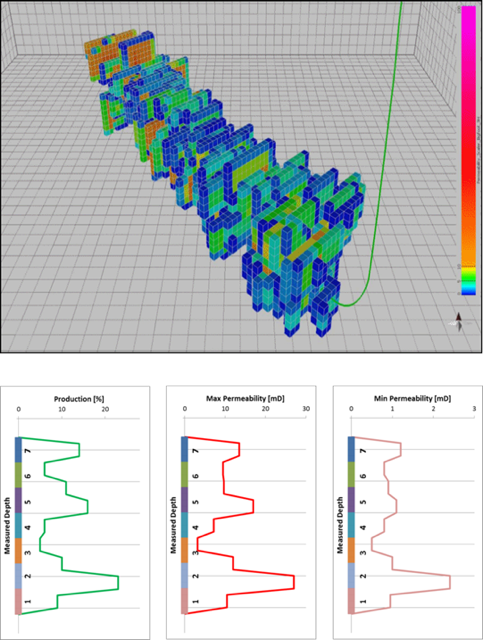

Microseismic-based evaluation tool calculates system permeability

PermIndex is a proprietary microseismic-based permeability evaluation tool used to estimate bulk permeability for each fracture stage. Using the radial pressure fronts of microseismic events during hydraulic fracturing, PermIndex calculates effective system permeability on a stage-by-stage basis. Calculating permeability provides important parameters for reservoir history-matching and computation of effective drainage volume and helps operators improve production forecasting and EUR. PermIndex includes two important features: the Permeability Scalar and the Production Productivity Log. The Permeability Scalar captures the fracture intensity at any given point in space and can provide a realistic estimate of variation in system permeability within the volume impacted by hydraulic fracturing. The Production Productivity Log allows the engineer to understand the productivity potential of each stage and can provide realistic constraints to reservoir simulation models. The Production Productivity Log, combined with the Permeability Scalar, allows the reservoir engineer to quickly and accurately achieve history-matching and to estimate drainage volume and EUR. MicroSeismic is exhibiting at booth 3943. microseismic.com

Frack sleeves can be opened and closed as needed to provide flexibility, control

NCS Multistage will be showcasing three new products at SPE ATCE. The MultiCycle frack sleeves are the first reclosable frack sleeves in the oil field. They can be opened and closed as needed to provide flexibility and control for completion, production and refracturing operations. The AirLock casing buoyancy system facilitates landing casing in horizontal wells at nominal cost and without interrupting casing and cementing operations. The AirLock system allows the vertical casing section to be filled with fluid, while the lateral section remains air-filled and buoyant. The enhanced buoyancy reduces sliding friction by more than 50%, while the weight of the vertical section provides additional force to push the string all the way to the toe. Finally, the Vector Max hydraulic-set liner hanger features a metal-tometal seal and a sure-running design that minimizes the risk of premature setting or unplanned running tool release. ncsmultistage.com

Monitoring system operates independently of completion system

The ePLUS Retina monitoring system is designed to verify downhole events, detecting multistage completion system operations and their effects on the reservoir. The self-contained monitoring unit operates independently of a completion system and does not interfere with stimulation operations. Specially designed sensors relay information from the well to the Retina monitoring system, which takes up a small footprint on location, and there are built-in redundancy features for all measurements to ensure timely and accurate data are being captured. One of the major challenges in multistage stimulation is visualizing downhole operations. Traditionally, surface pressure signatures are used to monitor

operations and indicate certain completion system events, including a ball landing on seat or a fracture port shifting open. However, in some cases the signature is not present or clear due to factors such as formation pressure, pump rate or data acquisition rate. This uncertainty can lead to costly delays. The Retina monitoring system can provide a cost-effective way for operators to visualize their multistage completions, enabling on-the-fly operational adjustments to ensure a successful stimulation, and can provide information for future wells. packersplus.com

Reservoir modeling technologies help capture deeper insights into the reservoir

Understanding and capturing reservoir connectivity is the cornerstone of any reliable reservoir modeling study. It almost guarantees faster history-matching and provides confidence when predicting future reservoir performance. During SPE ATCE, Paradigm will unveil its Paradigm 15 release, which can bring improved accuracy to reservoir modeling. Paradigm’s SKUA-GOCAD interpretation-to-modeling platform provides the ability to combine multiple sources of information to control the distribution of reservoir rocks away from wells, to model compartments, to capture the impact of fault position uncertainty on production forecasts and to build flow simulation-ready grids for the most adverse geological settings. To validate interpreted compartments, the Paradigm Interpret well test interpretation solution can provide deeper insights into the reservoir through a new implementation of pressure transient deconvolution. pdgm.com

Corrosion-resistant alloy designed for harshest environments

PCC Energy Group offers a range of high-performance alloy solutions that can stand up to the harshest offshore environments. PCC’s alloys, produced collaboratively by its companies, are incorporated into a number of products, including corrosion-resistant oil country tubular goods, umbilical tubing, CO-X co-extruded clad pipe, titanium stress joints and high-yield steel fittings, which will all be on display at SPE ATCE 2015. Additionally, the company will be showcasing its strongest and most corrosion-resistant superalloy yet: the INCOLOY alloy 945X. As the energy market continues to demand access to harsher and more damaging environments, 945X has the qualities to stand up to these forces and work reliably to curb downtime. pccenergy.com

Development programs, competency building help company workforces

Whether a company is seeking a basic training course for new-hire engineers or a complete organizational competency development program, PetroSkills offers deep industry experience and competency building expertise useful in helping develop a company’s workforce. Industry-validated competency maps form the framework for all PetroSkills solutions, define benchmarks for competency and outline the knowledge and skills required for major disciplines. Driven by these standards, PetroSkills’ learning resources encompass the full spectrum of industry knowledge and skills needed to create comprehensive workforce solutions. The company’s broad industry know-how includes instructors and subject-matter experts averaging 35 years of real-world experience in a range of technical subjects. This extensive collective knowledge, combined with advanced web technology, helps the company’s clients develop, support and manage workforce competency and compliance. petroskills.com

Nonintrusive flowmeters designed to have more accurate decline curves

Pietro Fiorentini surface and subsea multiphase and wet gas flowmeters provide real-time simultaneous measurement of oil, water and gas flow rates. The meters measure the three phases flowing together without separation, eliminating the need for separation before measurement and avoiding installation of large and costly equipment. The meters are nonintrusive, operate in-line and have more accurate decline curves, permitting accurate reserves calculations that can help the development strategy. The meters offer reduced drilling and completion costs by better understanding interference between wells and better characterizing the stimulation zone. Other advantages include optimized production by observing continuous flow rates and increased data confidence, allowing earlier recognition of wells problems. Additionally, the technology’s adaptable and modular design allows adding modules as the well flowstream changes during its life cycle. The additional modules can be added to the system, improving the accuracy and extending the operating range. fiorentini.com

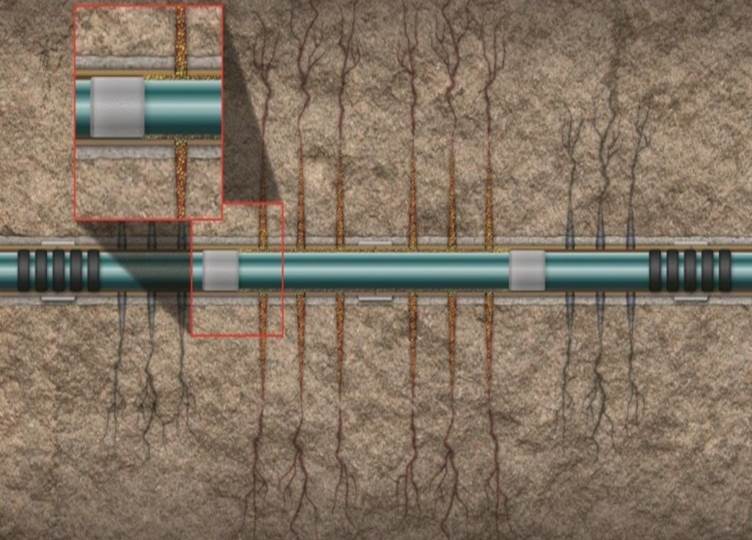

Tracer technology obtains production profile of the well

RESMAN Intelligent Tracers are used to monitor the inflow of oil and water for years of a well’s life without intervention operations. The technology works by integrating the Intelligent Tracers within the completion hardware. The Intelligent Tracers mark the production from individual reservoir intervals with an identifiable chemical signature, which can be analyzed and modeled to obtain a production profile of the well. RESMAN experimentally verified the validity of its inflow quantification model (the Flush Out model) in a fullscale flowloop test with joint industry project partners Eni and Statoil, demonstrating that the Flush Out model can quantify inflow within 5% accuracy. The information obtained provides the equivalent of a production log but without the risk and cost of well interventions. Applications include quantification of oil inflow contribution, water breakthrough monitoring, inflow assurance monitoring and detection of condensate banking and gas breakthrough. resman.no

Proppants feature magnetic susceptibility that is detectable using wireline tools

At SPE ATCE 2015, Saint-Gobain will feature a new line of proppants that enables precise detection of proppants placement in the fracture. The proppants possess a magnetic susceptibility, that is detectable using common magnetic susceptibility wireline tools. The exceptional strength of the proppants ensures survival in the fracture even in the deepest offshore wells. Unlike conventional tracer proppants, the magnetic susceptibility attribute is a permanent proppant property, and strength of the signal does not decay with time, therefore allowing measurements to be taken at any time during completion or the production life of the well. This then enables operators to gain insight into not only the initial fracture geometry but also the fracture geometry evolution over the life of the well. proppants.saint-gobain.com

APS surfactants feature improved thermal stability

Common alcohol propoxy sulfates (APS) are broadly used for chemical EOR and in various oilfield applications. However, their use is limited up to 60 C (140 F) due to the thermal stability of these compounds. SASOL has developed APS with improved thermal stability. The new ALFOTERRA M surfactant series includes APS that are proven stable up to 70 C (158 F), and in some cases up to 80 C (176 F), for months. In addition, these new compounds retain the performance properties of the traditional ALFOTERRA surfactants, like small application concentration, Winsor III behavior and ultralow interfacial tension, and will be delivered as a high-active (greater than 90%), water-free material with low viscosity. Hence, the gap between the low-temperature application of the conventional APS surfactants and the high-temperature surfactants is closed. sasol.com

ESP deployment system replaces ESPs without a rig or hoist

The ZEiTECS Shuttle is an electric submersible pump (ESP) deployment system that enables ESPs to be run and replaced without a rig or hoist. A downhole electrical wet-connector technology enables standard ESPs to be run through tubing on wireline, coiled tubing or sucker rods and to connect into a downhole docking station. The ability to replace ESPs conveniently and inexpensively without a rig can reduce life-cycle costs and deferred production for clients, thereby prolonging well and field economic viability and increasing producible reserves. The ZEiTECS Shuttle system is an integral part of the Schlumberger technology portfolio, which focuses on maximizing production and ultimately reducing system life-cycle cost. slb.com

Subsea vibration data loggers designed for low-frequency motions

To service the emerging need to collect high-quality vibration data under increasingly stringent subsea environments, Stress Engineering Services has developed a Subsea Vibration Data Logger (SVDL). The SVDL is available in two configurations: real-time (interconnected real-time fatigue monitoring system) and standalone (battery-powered vibration recorder). The SVDL was designed specifically for the low-frequency motions experienced by subsea equipment, incorporating high-precision sensors and electronic components. Benefits of monitoring using SVDLs include operational safety, risk reduction, maximization of uptime and operational efficiency, and improvement of overall upstream profitability. The real-time SVDL system has been used by JAMSTEC while drilling under the direct influence of the Kuroshio current (4-knot to 5-knot surface current). Under such current, the drilling riser might be exposed to fatigue-life consuming vortex-induced vibrations (VIV). The system provided real-time stress and fatigue damage data for the entire drilling riser, using only seven SVDLs on the 1,829-m (6,000-ft) riser. Standalone SVDLs were recently employed by Shell while drilling in 1,829 m of water with 4-knot to 5-knot surface currents, including 1 knot submerged currents extending to more than 1,000-ft (305 m) depth. Fast turnaround of SVDL data enabled fatigue life consumption to be tracked during periods of strong VIV. This enabled the well to be successfully drilled to depth under the most onerous of conditions. stress.com

Toe sleeve carries out CIT without damaging the casing during overpressuring

TAM International released its new PosiFrac Toe Sleeve (PTS) to the market in April. The design of the PTS allows operators to perform a casing integrity test (CIT) up to the full burst rating of their casing. Unlike other toe sleeves on the market, which are based on frangible devices such as a rupture disc or shear wire, TAM’s PTS does not require overpressuring of the casing once the test is complete to establish communication with the formation. Once a successful test is achieved, the tool will open upon bleed-down from the test pressure. This technology allows the operator to carry out the CIT without damaging the casing during overpressuring and, in certain cases, provides positive feedback that the toe is open to the annulus. The design enables the PTS to open on bleeddown and uses the tool’s response to the very high forces that act on the piston area of the sleeve portion of the assembly. When that effective area sees pressure, the sleeve opens, which can potentially provide positive feedback at surface that the tool has opened as designed, ensure the sleeve is fully opened and locked in place via the lock ring, and mitigate any potential risk associated with cementing the sleeve in place. The tool is designed with features such as large flow areas to help ensure quality stimulation out of the toe stage; the ability to run multiple tools and have them open concurrently to provide a better stimulation profile, if required; and large inside diameters that not only accommodate stimulation and production but also eliminate the need for specialty cement wiper plug sets. The simple design of the actuation system can further provide for extremely high reliability and minimal configuration. A single configuration, with the exception of one variable, can accommodate all pressures and temperatures across all basins. tamintl.com

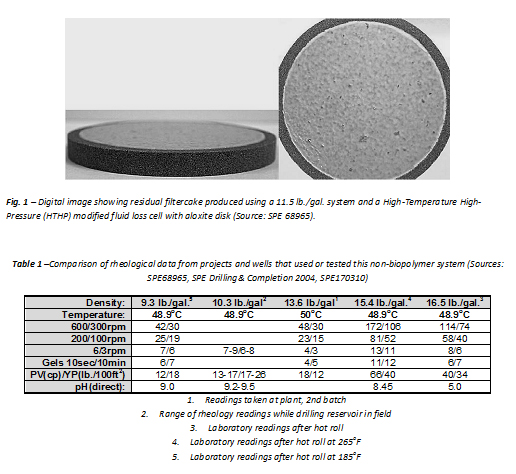

Aqueous-based system reduces risks associated with D&C challenges

A reservoir drill-in system was developed by TBC-Brinadd LLC and initially introduced in 2001 as a nonbiopolymer system whereby in lieu of traditional xanthan and similar gums, it used only an acid or enzyme soluble polymer to serve both as a viscosifier and a fluid loss additive. Recent advances now provide additional flexibility for this system, which can be used in many challenging environments, thus accommodating operators and their drilling and completion (D&C) projects to reduce risks associated with fluids. Recent optimization now allows the blending to a final density as low as 9 lb/gal using modified starch, inorganic magnesium compound, selected bridging/weighting material and relatively inexpensive calcium chloride as a base plus an inorganic magnesium compound (Table 1). At this density, the system is still biopolymer-free, and low-shear-rate viscosity remains elevated such that hole cleaning does not decline. In addition, a recent D&C project demonstrated that the incorporation of an inhibitor prevented near-wellbore scaling during the D&C phases. This system is provided by M-I SWACO LLC, a Schlumberger company. slb.com/services/miswaco.aspx

Forging process allows development of safer landing string for deepwater applications

The offshore industry’s current trend is driving toward ultradeepwater wells, combined with deeper total depths. To be able to set and run larger and heavier casing strings with hook loads approaching or exceeding 2.5 million lb, a heavy-duty landing string system has been developed by Vallourec. Such systems must be capable of landing heavy loads while ensuring slip crush resistance. One of the current operational challenges with existing heavy-duty landing strings is linked to the positioning of the slips, in particular when using extended slip designs and eliminating the risk of setting the slips on any weld or heat-affected zone. Hence, a forging process has been used to produce seamless forged landing strings. The technology involves a hot forming process using a four-hammer forging machine on a cylindrical mandrel. The main advantage of this technology is to achieve improved dimensional tolerances, shaped tubes and metallurgical properties. Vallourec’s forged CrushFree landing string has been industrially manufactured this year and is now available to the market. vallourec.com

Water treatment services recover resources from produced water for reuse

Veolia’s produced water treatment solutions are designed to eliminate the risk and liability associated with produced water management and disposal. Added benefits are EOR to increase production, reduced lease operating expenses and recovered resources from the produced water such as salt byproducts and freshwater for reuse in operations, irrigation or surface discharge. The company’s fully integrated systems operated by trained Veolia personnel come with a performance guarantee that enables customers to focus on what they do best—extracting and producing oil and gas—with the peace of mind that their water is in the hands of water experts. The company’s latest ceramic membrane-based innovations—ROSS and OPUS II technologies—will be among those showcased at booth 4102. veoliawatertechnologies.com/en

Compact hydraulic long-stroke pumping unit requires no site preparation, installs quickly

The Weatherford EnviroLift hydraulic long-stroke pumping unit is a lift solution that is well suited for multiwell pads, environmentally sensitive areas and populated areas. It provides similar capabilities as a conventional pumping unit—but in a more compact, environmentally friendly package that enhances safety—and eliminates problems associated with other hydraulic technologies. The unit is suited for deviated and horizontal wellbores and for liquid production up to 1,200 bbl/d (191 cu. m/d). The unit comes in three parts that require no site preparation and install quickly: the wellhead, cylinder assembly and power unit. The 240-in. stroke unit is rigidly bolted and supported on the integrated wellhead—eliminating guy wires while enabling the unit to withstand 100-mph winds—and is contained in a single cylinder with no exposed moving parts. The design eliminates the stuffing box to avoid leaks. With a maximum skid size of 3.4 m by 1.8 m (11 ft by 6 ft), the unit enables higher well density and increased productivity in multiwell pads and provides plenty of workspace. Additionally, with options for camouflaging and noise reduction to blend into the surrounding landscape, the unit can be aesthetically pleasing. weatherford.com

Pump features wiper assembly and filter to keep sand out of plunger, barrel

When producing in sandy wells with reciprocating rod-lift systems, wear can occur at unacceptable levels. Abrasive sand accumulating within the barrel/plunger interface damages both the barrel and the plunger, thereby shortening pump life, reducing production rates and increasing operating costs. The Weatherford Sand-Tolerant Pump (STP) can restore economic viability to sandy, rod-pumped wells. Based on ongoing tests, the STP works in sandy conditions more than six times longer than conventional rod pumps by lubricating the plunger/barrel interface with filtered production fluid. The STP features a wiper assembly and filter coupling for efficient, reliable performance. The outside of the wiper assembly creates a barrier that keeps sand out of the plunger/barrel interface by continually wiping the inside of the barrel while the pump produces sandy fluid to the surface. The filter coupling houses an internal screen that only allows clean produced fluid to pass through the equalization ports to the interface and lubricate the pumps. Because the filters move with the plunger, the sweeping action of the fluid on the downstroke cleans the filters and keeps sand suspended within the production fluid. The sand-laden fluid is then produced through the center of the plunger to the surface. weatherford.com

Recommended Reading

E&P Highlights: April 8, 2024

2024-04-08 - Here’s a roundup of the latest E&P headlines, including new contract awards and a product launch.

E&P Highlights: Feb. 5, 2024

2024-02-05 - Here’s a roundup of the latest E&P headlines, including an update on Enauta’s Atlanta Phase 1 project.

E&P Highlights: Feb. 26, 2024

2024-02-26 - Here’s a roundup of the latest E&P headlines, including interest in some projects changing hands and new contract awards.

E&P Highlights: March 15, 2024

2024-03-15 - Here’s a roundup of the latest E&P headlines, including a new discovery and offshore contract awards.

NAPE: Chevron’s Chris Powers Talks Traditional Oil, Gas Role in CCUS

2024-02-12 - Policy, innovation and partnership are among the areas needed to help grow the emerging CCUS sector, a Chevron executive said.