The construction site of a Marcellus shale gas drilling operation is shown in rural northern Pennsylvania. (Source: George Sheldon/Shutterstock.com)

HOUSTON—Recovery rates of about 20% for shale gas and less than 10% for liquid-rich plays show there is still room for improvement for U.S. shale plays.

The U.S. Department of Energy, working with industry players and academia, is on a mission to change that as it works to better understand unconventional reservoirs and help bring new technology and improved techniques to fields.

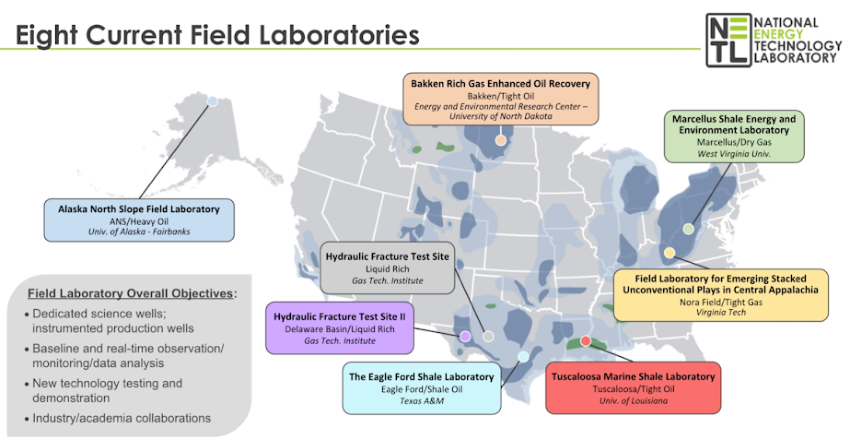

Jared Ciferno, oil and gas technology manager for the energy department’s National Energy Technology Laboratory (NETL), spoke about some of the research efforts underway at the recent Gastech Exhibition and Conference. NETL’s roughly $50 million a year unconventional resource development program aims to maximize recovery and lower operational impacts.

“Industry has done a fantastic job of improving and optimizing hydraulic fracturing and really going after whether it’s dry gas or oil or wet gas,” Ciferno said. “Significant progress has been made over the last 10 years. We recognize that. However, depending on where you’re at, what location, you still have relatively little recovery.”

Plus, decline curves are still steep for unconventional wells. Other challenges, he explained, include a poor understanding of fluid, water and rock interactions, and inability to precisely depict hydraulic fractures. The industry lacks technologies that enable drillers to see what’s happening a mile or two away from the wellbore, he said, noting technologies are being developed today.

“The current thrust of our program [are] field-based studies to evaluate new technologies in addition to getting these first-of-kind technologies evaluated at scale in the field on a particular stage,” Ciferno said. “We’re also collecting substantial amount of data from raw cores in the field [and conducting] field-based studies to look at enhancing oil recovery. This is both unconventional EOR as well as conventional EOR.”

Here’s a look at work underway at some of the NETL’s field laboratories.

Marcellus Shale Energy and Environmental Laboratory

Located near Morgantown, W.V., the two-phase project brings together Northeast Natural Energy (NNE), Schlumberger, West Virginia University, High Point Construction and The Ohio State University.

Researchers aim to develop integrated data acquisition and modeling approaches for reservoir-scale simulations using geophysical data, image logs and lithology; scrutinize fracture stage designs and evaluate stage spacing and cluster density; and improve rock characterization by integrating geophysical, fluid flow, mechanical properties logs, microseismic and core data, according to NETL. The team is also matching reservoir lithology and fracture-fluid types to better understand how fluids and gasses interact with reservoir rock over the long term.

“We’re actually in the process of drilling six wells,” Ciferno said. The wells are at the Boggess site near Core, W.V. “In addition to the subsurface science, we’re going to do our first ever machine learning application to those six wells.”

Phase 1 of the project, which began in 2015, involved two NNE wells from which core was obtained. Fiber-optic cable for distributed acoustic sensing and distributed temperature sensing measurements was installed on one of the wells through the full lateral length, Ciferno said in a report. A vertical science well was also drilled between the two horizontal wells and equipped with microseismic sensors to get data during the fracking process.

Researchers concluded, among other findings, that engineered completion designs resulted in about a 20% increase in production compared to NNE’s standard completion techniques. NETL said that EUR for future wells could increase by about 10% to 20% if operators use insight gained from through the project.

Phase 2, which is underway, also focuses on improving gas recovery using less expensive alternative imaging options. It’ll include logging-while-drilling techniques.

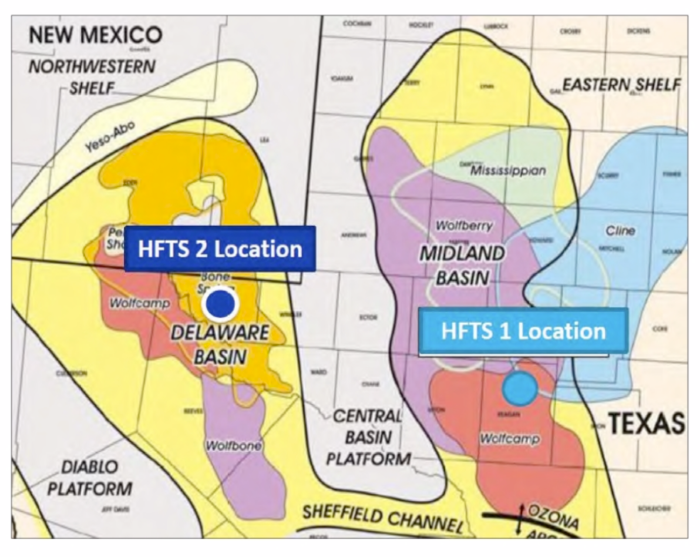

Hydraulic Fracturing Test Site (HFTS) I Permian Basin

NETL partnered with several Permian players—including Laredo Petroleum Inc. and Halliburton—and the Gas Technology Institute in Reagan Co., Texas. “The objective here is understanding the hydraulic fracturing process in the Wolfcamp Formation,” Ciferno said.

The project included drilling a slanted core well between two horizontal laterals to intersect hydraulic fractures. In addition, a vertical pilot well was drilled to gather core and log data.

Accomplishments, as explained by Ciferno, included completing more than 400 fracture stages in 11 wells, diagnostic fracture injection tests and microseismic monitoring during fracturing, looking to predict hydraulic fractures and where proppant would go.

Pressure sensors were also used in the slant well to monitor pressure during production.

Researchers found that five times as many fractures were seen in the Upper Wolfcamp compared to the Middle Wolfcamp, leading them to believe that more perforation clusters and tighter stage spacing are needed in the latter to stimulate more rock.

They also found that “Proppant distribution is limited to <10 percent of vertical hydraulic fracture height. Bed boundaries have significant impact on limiting vertical proppant transport. Significant amounts of proppant are trapped where fractures intersect, limiting lateral transport into the formation,” according to Ciferno’s report.

Phase 1, which included collecting pressure, temperature and production data from test wells, is finished. Phase 2, currently underway, seeks to find the effectiveness of cycling gas injection, or huff-n-puff, for increasing oil recovery, he said.

The NETL also has another hydraulic fracturing test site in the Permian’s Delaware sub-basin, where it is working to optimize well completion designs working with another set of partner companies. Among the project goals is to determine optimum well spacing and fracture design, complete 3-D earth models of reservoir simulation and fracture evaluation and study microbial impacts on reservoir quality, he said.

Alaska North Slope Field Laboratory

Farther north at the Milne Point Unit on Alaska’s North Slope, the NETL is working with Hilcorp Energy Co., the University of Alaska Fairbanks, New Mexico Institute of Mining and Technology, Missouri University of Science and Technology and the University of North Dakota to “evaluate a process that integrates polymer flooding, low salinity water flooding, horizontal injection and production wells, and conformance control treatments to improve recovery of viscous oil from the Schrader Bluff Formation.”

Primary recovery rates for this heavy-oil area are around 10-15%, according to Ciferno.

The project, he said, will be the first ever polymer flood on the North Slope.

Hilcorp, which in August bought BP’s Alaskan properties in a $5.6 billion deal, is providing three lateral wells and monitoring wells, while the NETL is providing monitoring and diagnostic technologies.

“We’re hoping to see results within the next year or so,” Ciferno said.

NETL also has ongoing projects in the Bakken, Eagle Ford, Tuscaloosa Marine Shale and Central Appalachia. It also has plans to award 11-15 new projects.

Recommended Reading

Comstock Continues Wildcatting, Drops Two Legacy Haynesville Rigs

2024-02-15 - The operator is dropping two of five rigs in its legacy East Texas and northwestern Louisiana play and continuing two north of Houston.

NAPE: Chevron’s Chris Powers Talks Traditional Oil, Gas Role in CCUS

2024-02-12 - Policy, innovation and partnership are among the areas needed to help grow the emerging CCUS sector, a Chevron executive said.

Chevron Hunts Upside for Oil Recovery, D&C Savings with Permian Pilots

2024-02-06 - New techniques and technologies being piloted by Chevron in the Permian Basin are improving drilling and completed cycle times. Executives at the California-based major hope to eventually improve overall resource recovery from its shale portfolio.

NAPE: Turning Orphan Wells From a Hot Mess Into a Hot Opportunity

2024-02-09 - Certain orphaned wells across the U.S. could be plugged to earn carbon credits.

CEO: Continental Adds Midland Basin Acreage, Explores Woodford, Barnett

2024-04-11 - Continental Resources is adding leases in Midland and Ector counties, Texas, as the private E&P hunts for drilling locations to explore. Continental is also testing deeper Barnett and Woodford intervals across its Permian footprint, CEO Doug Lawler said in an exclusive interview.