Preventing fluid losses during slurry placement is generally necessary when implementing a cost-effective cement design. Achieving effective zonal isolation behind the casing of the liner wall is intimately related to preventing losses toward the formation as well as flow from it during and after the cement circulation.

When cementing a casing or liner string within limited margins, maintaining the bottomhole circulating pressure below the fracture gradient in many cases is not possible when implementing conventional cementing techniques. In most cases, this condition can lead to fluid loss while cementing, additional costs to conduct a logging operation to evaluate cement results and remedial operations to comply with regulations.

Cementing fluid dynamics are generally more complex than those during the drilling phase. Narrow annular spaces, combined with multiple fluids being pumped at different rates with diverse properties, make it difficult to accurately predict the annular temperatures and pressures profiles to be obtained during the cement circulation. When a narrow pressure window between the pore and fracture gradients are added to the mix, the cementing operation becomes even more challenging. State-of-the-art MPD control systems and hydraulic modeling software have extended the reach of the surface pressure control approach to include well cementing.

Case study

Since 2018, several deepwater wells in the Gulf of Mexico (GoM) have demonstrated the advantages of managed pressure drilling (MPD) in challenging offshore environments. On these wells, all riser sections were drilled, cased and cemented using statically underbalanced mud weights combined with the application of surface backpressure control to maintain annular pressures within the available operating window, which at some depths was as narrow as 0.3 lb/gal equivalent. There was zero nonproductive time related to mud losses or well control recorded, and major capex savings were achieved by the operator as compared to past conventional drilling operations in the area in similar wells.

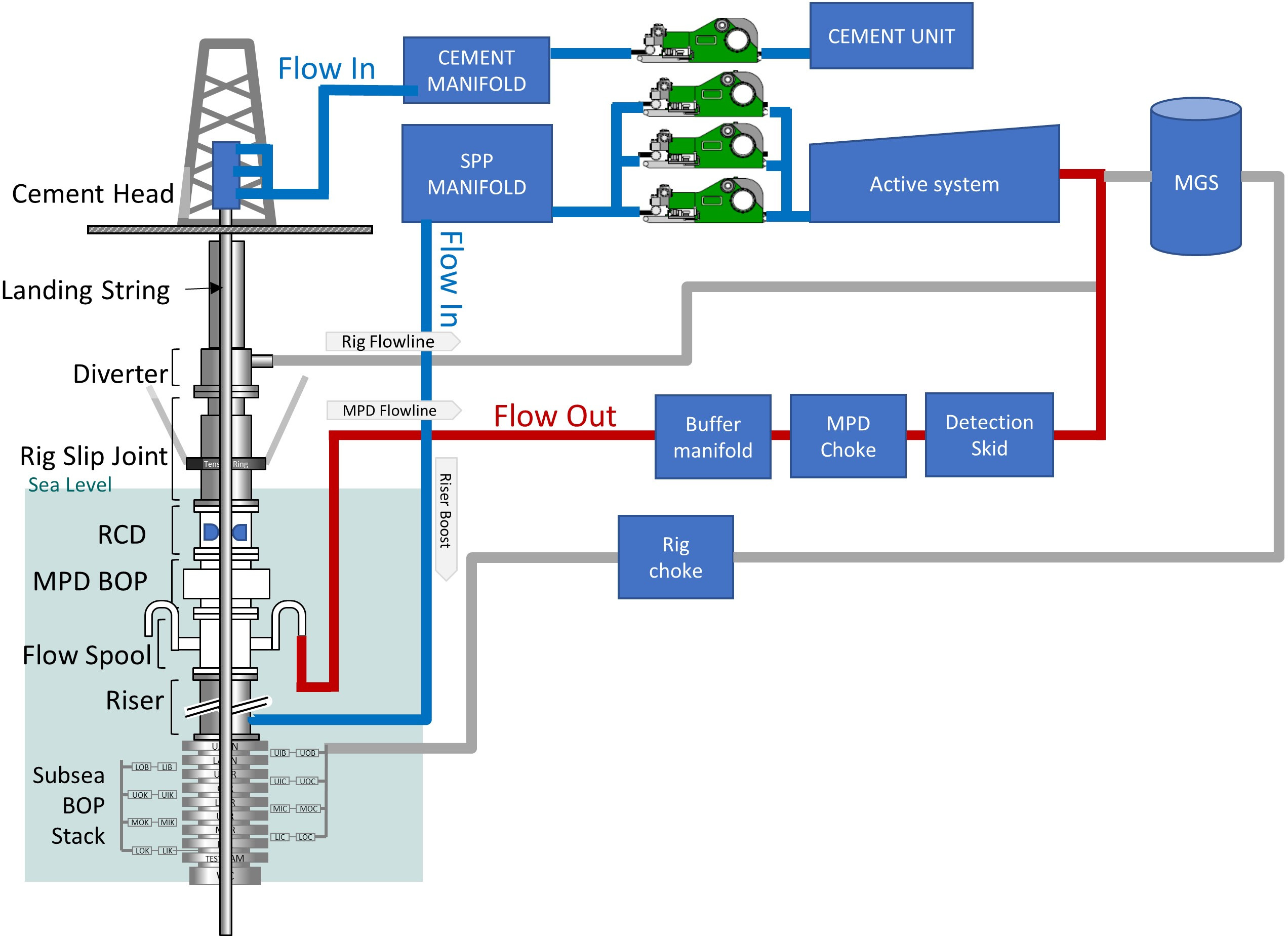

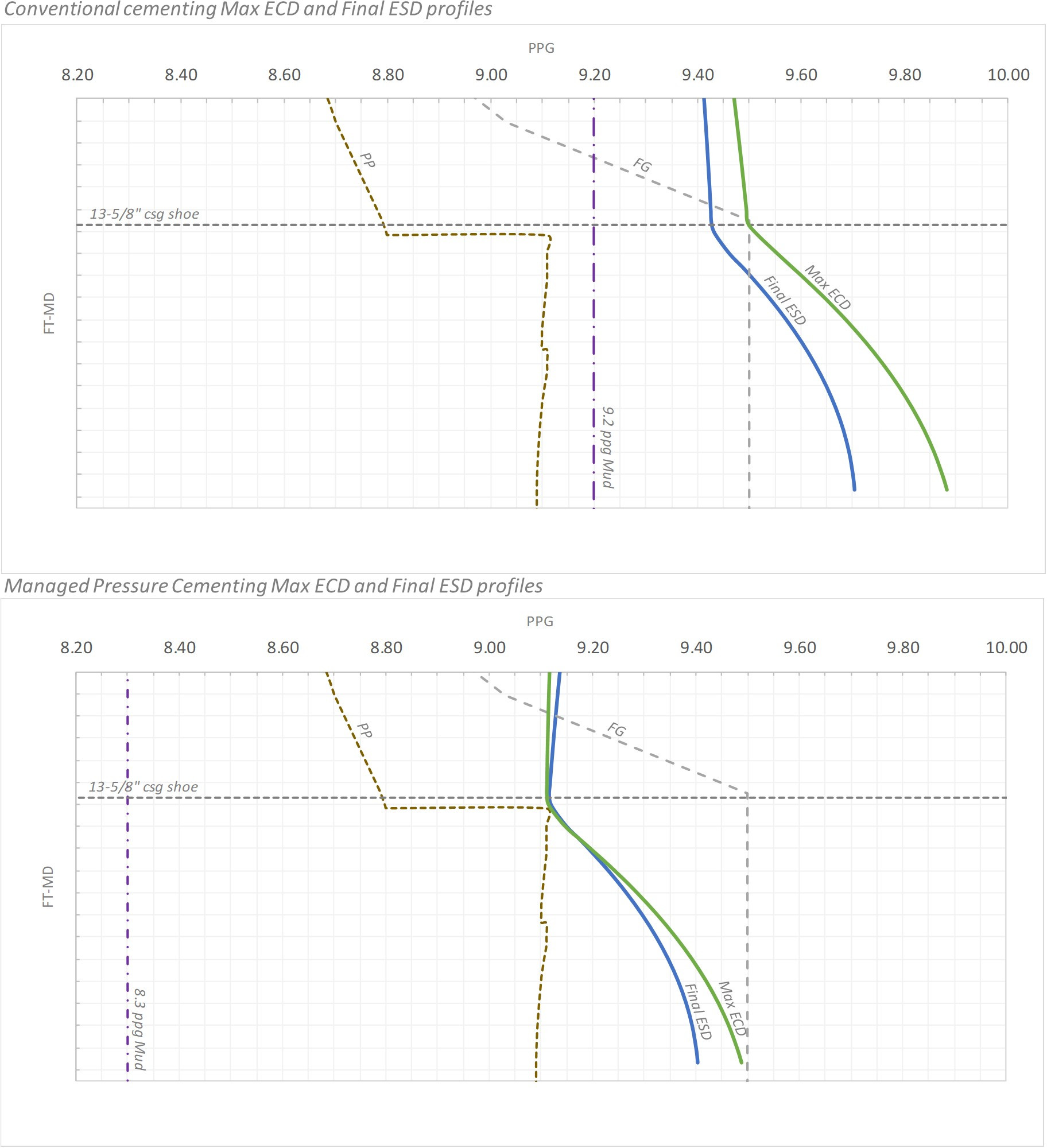

The greatest well construction challenge for these deepwater wells is to cement within a narrow window due to high equivalent circulating densities (ECDs) that needed to be obtained. Given the limited margins that are verified by the operators while drilling, conventional cementing for the lower strings were unfeasible without expecting severe losses. Weatherford developed a structured engineering process to solve the high ECD levels issue during cementing by creating pump schedules that worked with surface backpressure to permit the use of statically underbalanced mud weights. The objective was to maintain annular pressures within the available margins throughout the cement job (Figure 1).

The main limitation for conventional cementing within a limited margin is the fact that the fluid properties and annular space configurations lead to peak ECDs and final equivalent mud weight columns that exceed the fracture limit at the final stages of the cement job. The peak or max ECD is reached when at the instant prior to shutting down the cement pump. At this moment, the spacer and slurry volumes are contributing at the maximum effect on the bottomhole hydrostatic pressure as well as to the annular frictional pressure loss in the annular space.

To address the issue using the MPD methodology, the bottomhole pressure (BHP) plan for the cement job is based on the analysis, modeling and manipulation of all the variables affecting annular pressure profile and BHP during the cement job. The objective of the managed pressure cementing (MPC) calculation during the planning phase is to find the right set of conditions and the required surface backpressure levels that will lead to annular pressures within the available operational window throughout the entire cementing operation.

The engineering process implemented to plan the MPC operations on these wells consisted of three main stages: data collection, MPC engineering and program elaboration.

Data collection could be one of the most important stages of the engineering planning of any well operation. Accurate data from all parties involved in the cementing operation are necessary to reduce the number of assumptions to be made during the modeling and iteration phase. Some of the most relevant information utilized to plan the operation included pore pressure, wellbore stability and fracture profiles, geothermal profile, well survey, mechanical configuration details and mud properties. In addition, accurate information from the pumping services company was crucial regarding the cement properties, volumes, intended densities and pumping conditions based on its experience to obtain proper isolation. The data collection also includes the inputs from the operator regarding the goals and targets to be accomplished during the job.

During the MPC engineering process, the gathered information is used to calculate and predict the annular temperatures and pressures to be obtained during the cement job. Besides evaluating variations of the circulating conditions and surface pressure, additional variables can be manipulated to evaluate the effect of the adjustment on the resultant pressure profiles. Fluid densities, viscosities, volumes, water-oil ratios and other fluid properties can be adjusted as operationally practical to find a set of conditions that, complemented with the application of surface backpressure, will enable the annular pressure profile to fit within the available margin throughout the entire operation (Figure 2).

The last step of the implemented MPC engineering process included the MPC program creation and disclosure. Once all calculations were done, it was considered of paramount importance to communicate the results, instructions and suggestions in a clear way to all personnel involved in the cement job. The surface backpressure plan and actions needed to be communicated clearly to the MPD crew on site to facilitate a smooth execution and prevent any confusion or misunderstandings. The cement representatives, site supervisors and operator’s engineers and supervisors who were making the operational decisions needed to have a clear understanding of the calculations performed and the inputs used as well as the pressures, flow rates and sequence of actions to be conducted during the cement jobs.

Recommended Reading

Renewed US Sanctions to Complicate Venezuelan Oil Sales, Not Stop Them

2024-04-19 - Venezuela’s oil exports to world markets will not stop, despite reimposed sanctions by Washington, and will likely continue to flow with the help of Iran—as well as China and Russia.

US Threatens to Not Renew Venezuelan Energy Sector License

2024-01-31 - The U.S. Department of State alerted Venezuela that it could decide not to renew General License No. 44 amid what Washington has labeled “anti-democratic actions.”

US Orders Most Companies to Wind Down Operations in Venezuela by May

2024-04-17 - The U.S. Office of Foreign Assets Control issued a new license related to Venezuela that gives companies until the end of May to wind down operations following a lack of progress on national elections.

US Decision on Venezuelan License to Dictate Production Flow

2024-04-05 - The outlook for Venezuela’s oil industry appears uncertain, Rystad Energy said April 4 in a research report, as a license issued by the U.S. Office of Assets Control (OFAC) is set to expire on April 18.