(Source: Hart Energy)

[Editor's note: A version of this story appears in the June 2020 edition of E&P. Subscribe to the magazine here. It was originally published June 1, 2020.]

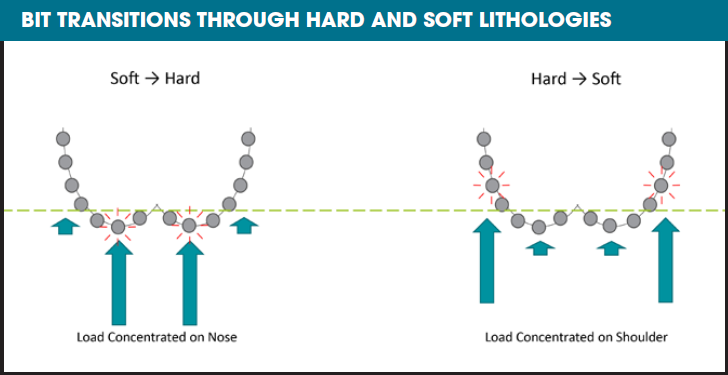

Transitional drilling and interfacial severity are the buzz words of the drilling industry right now. Essentially, they refer to the same problem—to drill through layers of varying rock types and strengths. As the bit moves through these transitions, the cutting structure is subjected to uneven forces in different parts of the profile, which can overload and damage cutters, shortening bit life and leading to unplanned trips. These uneven forces also can be transmitted up the drillstring in the form of harmful vibrations, which could increase the risk of tool failures in the buttonhole assembly (BHA).

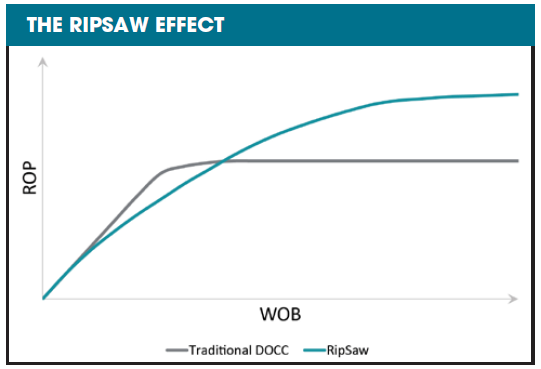

The way to control this uneven loading is to manage the drill bit’s depth of cut (DoC); if the bit can be stopped from taking too big a bite of the formation, the magnitude of the uneven forces through that transition can be reduced. Drill bit manufacturers have used a few methods to control DoC. Historically, this was done using hard-stop surfaces such as the blade top or inserts behind the cutter. This very effectively stops the bit from taking that bigger bite, but by tuning that DoC control for the transitions, it also prevents the bit from achieving high instantaneous ROP.

Having the bit lean on these hard surfaces while drilling also causes increased friction, which can cause torsional vibration. To solve these problems, manufacturers have recently started experimenting with moving DoC control elements built into the bit, but the added complexity of moving parts in the bit face brings a whole new set of risks.

Drilling the Permian Basin

The 12¼-inch intermediate section in the Permian Basin has one of the toughest transitional sections in the world. The upper part of the section is relatively easy and fast. But approximately two-thirds of the way through the interval, the bit will encounter the Brushy Canyon and Cherry Canyon formations that have a mix of hard carbonate lithologies interbedded with softer silicates and anhydrites. This part of the section defines whether a run will be successful or not. About 30% of bits don’t make it. While the rest will go on to section total depth (TD), that 30% must be pulled for an expensive trip and may be damaged beyond repair.

Seeking a solution to the transitional drilling problem, Ulterra engineers set to work brainstorming various options. By year-end 2019, the concept evolved into the new RipSaw product technology, which had quickly accumulated more than 2,000 runs and drilled 9 MMft of hole.

RipSaw uses a new form of active torque technology to manage DoC proactively using the cutting structure itself rather than passive elements in the bit face. At the core of this technology are high back rake cutters strategically placed in different parts of the profile. The more passive cutters resist rapid changes in DoC but, at the same time, still cut elements so as to not prevent high-instantaneous ROP when more weight on bit (WOB) is applied.

In this way they act like a shock absorber on a vehicle, protecting the occupant or bit from potholes and bumps while also allowing a smooth and compliant ride. In transitions, the higher back rake cutters prevent the more aggressive parts of the profile from over-engaging so the driller, rather than backing off to manage WOB, can lean on the bit and allow the RipSaw cutting structure to regulate itself.

In real world applications, this means less damage to the bit and BHA, better dulls and increased reliability, which ultimately lead to faster average penetration rates and a better chance of shoe-to-TD performances. In the current economic and drilling industry climate, the one thing that drillers need is better reliability so they can reliably plan well construction time and reduce cost overruns.

WOB into friction, whereas the new technology does not

prevent high ROP but controls high axial forces. (Source: Ulterra

Drilling Technologies)

Measuring success

The drill bit industry has typically focused on ROP as the primary and, at times, only demonstration of success, but a successful run can be measured in many other ways. Ulterra analysts wanted to show what increased reliability means in the real world, especially as the industry evolves to focus on delivering a quality wellbore with maximum efficiency. Performance data analysts pulled every comparable Permian Basin 12¼-inch intermediate run in the previous six months from Ulterra’s bit record database. This dataset consisted of 3,264 runs on 2,147 wells with more than 11 MMft of hole drilled for 128 different operators. Of these, 434 runs were with the new RipSaw technology, 1,320 with competitor bits and the remainder with other Ulterra products. With so many datapoints, the effects of outliers and one-offs were minimized and any findings from these data were guaranteed to be statistically significant.

The new active torque technology drilled on average 750 ft farther per run than all other bits from any manufacturer. The data also showed that this technology improved the shoe-to-TD rate by nearly 30%, delivering a one-run section nearly 90% of the time. Ulterra analysts then filtered the dataset for first runs out of the shoe and created risk profile graphs to demonstrate how likely it was that bits would reach any given depth. They found that bits equipped with RipSaw technology would have an 80% chance of hitting a critical depth that conventional products only managed 50% of the time.

In terms of well costs, that increased reliability translates to a 39% improvement in the cost per foot, applying standardized costs across the board for comparison. By extrapolating that number over the 1.8 MMft of hole drilled by RipSaw in this study, the results show that those 434 runs saved Permian operators more than $42 million in drilling costs. Moreover, if RipSaw technology had been used on every single run in the study, that amount would be more than $220 million, demonstrating that seemingly small gains in reliability translate into the potential for massive cost savings.

The challenge for Ulterra engineers is to expand the technology into other applications where active DoC control would bring benefits. Focus has now moved to long lateral sections and RipSaw technology has delivered longer runs, better tracking and improved toolface control.

The technology also will be highly effective in complex 3D directional wells where steering control and wellbore quality are essential to success.

Recommended Reading

Exclusive: Renewables Won't Promise Affordable Security without NatGas

2024-03-25 - Greg Ebel, president and CEO of midstream company Enbridge, says renewables needs backing from natural gas to create a "nice foundation" for affordable and sustainable industrial growth, in this Hart Energy Exclusive interview.

BKV CEO: Texas Grid Needs More Combined Cycle NatGas Plants

2024-04-12 - BKV CEO Chris Kalnin dives into the "core issue" of Texas' renewable grid and how the company is increasing production as the the largest producer in the Barnett Shale, in this Hart Energy Exclusive interview.

Venture Global, Grain LNG Ink Deal to Provide LNG to UK

2024-02-05 - Under the agreement, Venture Global will have the ability to access 3 million tonnes per annum of LNG storage and regasification capacity at the Isle of Grain LNG terminal.

WoodMac: Market Likely to Absorb Aramco’s Downshift in Oil Production

2024-02-02 - Saudi Aramco’s move from a targeted 13 MMbbl/d capacity by 2027 is not expected to tighten the supply and demand balance this decade, Wood Mackenzie analysts said.

Paisie: Economics Edge Out Geopolitics

2024-02-01 - Weakening economic outlooks overpower geopolitical risks in oil pricing.