Learn more about Hart Energy Conferences

Get our latest conference schedules, updates and insights straight to your inbox.

[Editor's note: This article originally appeared in the October issue of E&P Plus. Subscribe to the digital publication here.]

It would be no exaggeration to say that artificial lift has made a tremendous contribution to increased production in oil fields. More than 50% of oil wells use artificial lift techniques, such as pumps and injection methods, to boost production. It is estimated that the artificial lift equipment market amounts to almost $10 billion annually, enabling $800 billion of oil production per year.

Despite these impressive results in the oil segment, artificial lift has gained relatively little traction in gas wells, both conventional and unconventional. This is largely because until now there have been no artificial lift tools that can directly induce energy into the gas to increase production and recoverability. While operators have been able to get positive results using wellhead compressors, experience has shown that these devices can accelerate liquid loading, especially in unconventional wells, due to higher critical lifting velocity and lower production fluid density within the wellbore. The result is decreasing productivity and premature abandonment.

Downhole system uses magnetic technology

Upwing Energy has developed and tested a new Subsurface Compressor System (SCS) that significantly increases gas production and recovery while also alleviating liquid loading. The SCS is a cost-effective downhole system that uses advanced magnetic technology to eliminate the primary failure points of electric submersible pump artificial lift systems. Key components are a high-speed downhole compressor driven by a hermetically sealed high-speed permanent magnet motor and a magnetic coupling that conveys torque from the motor to the compressor with no mechanical shaft or seals. This architecture eliminates the need for a protector shield to isolate the motor from the downhole fluids. The system also includes a sensorless wide-frequency variable speed drive at the surface that controls the downhole motor at speeds of up to 50,000 rpm.

The SCS creates a suction effect at the compressor inlet at the bottom of the wellbore, thus lowering the bottomhole flowing pressure and increasing gas velocities in the wellbore, enabling more liquids to be carried to the surface. Decreasing backpressure from liquid loading results in increased gas production, which in turn accelerates liquid unloading and prevents vapor condensation when exiting the compressor.

The SCS architecture maximizes gas and condensate production, recoverable reserves, gas-in-place recovery efficiency and liquid unloading—all at the same time—while lowering total cost of ownership and reducing surface footprint. These benefits can be realized in any type of formation and wellbore geometry for both onshore and offshore environments.

Field trial

The first full-scale commercial SCS deployment took place over a two-month period in a liquid-loaded shale gas well operated by Riverside Petroleum in Indiana. The trial resulted in a 62% increase in gas production and a 50% increase in liquid production over its steady-state performance with a rod pump prior to the SCS installation.

For the Riverside demonstration, the SCS was deployed in an unconventional well with a 2,000-ft vertical wellbore and a 5,000-ft horizontal wellbore where liquid had accumulated. The compressor was installed at the bottom of the vertical section with a tail pipe extending approximately 1,000 ft into the horizontal section to provide enough velocity to carry liquids while minimizing friction losses.

Prior to installing the SCS, the well’s gas production was about 185,000 scf/d, and its liquid production via rod pump was 5 to 7 bbl/d. Without the rod pump, the well choked in a few hours. With the SCS, the well stabilized at a gas production rate of 300,000 scf/d. When the SCS operated at 30,000 rpm, the gas velocity increased to 29 ft/sec and a high rate of liquid was carried to the surface. The hybrid axial compressor was able to atomize the liquid into a very fine mist, which, together with the increased velocity and heat generated from the exit of the compressor, helped carry the liquids to the surface.

At the conclusion of the trial, the SCS was removed and inspected. The compressor blades showed no signs of degradation despite moving a significant amount of liquids.

The next major commercial trial for the Upwing SCS will take place in a higher flowing conventional gas well in the U.S. early next year.

Predictive tools

Modeling tools make it possible to evaluate and predict the outcome of conventional wells with the SCS. This is due to better understanding of the conventional reservoir, existing verified models and available historical data. Operators can insert the SCS compressor maps into their reservoir models and verify the incremental improvement in production and recoverability.

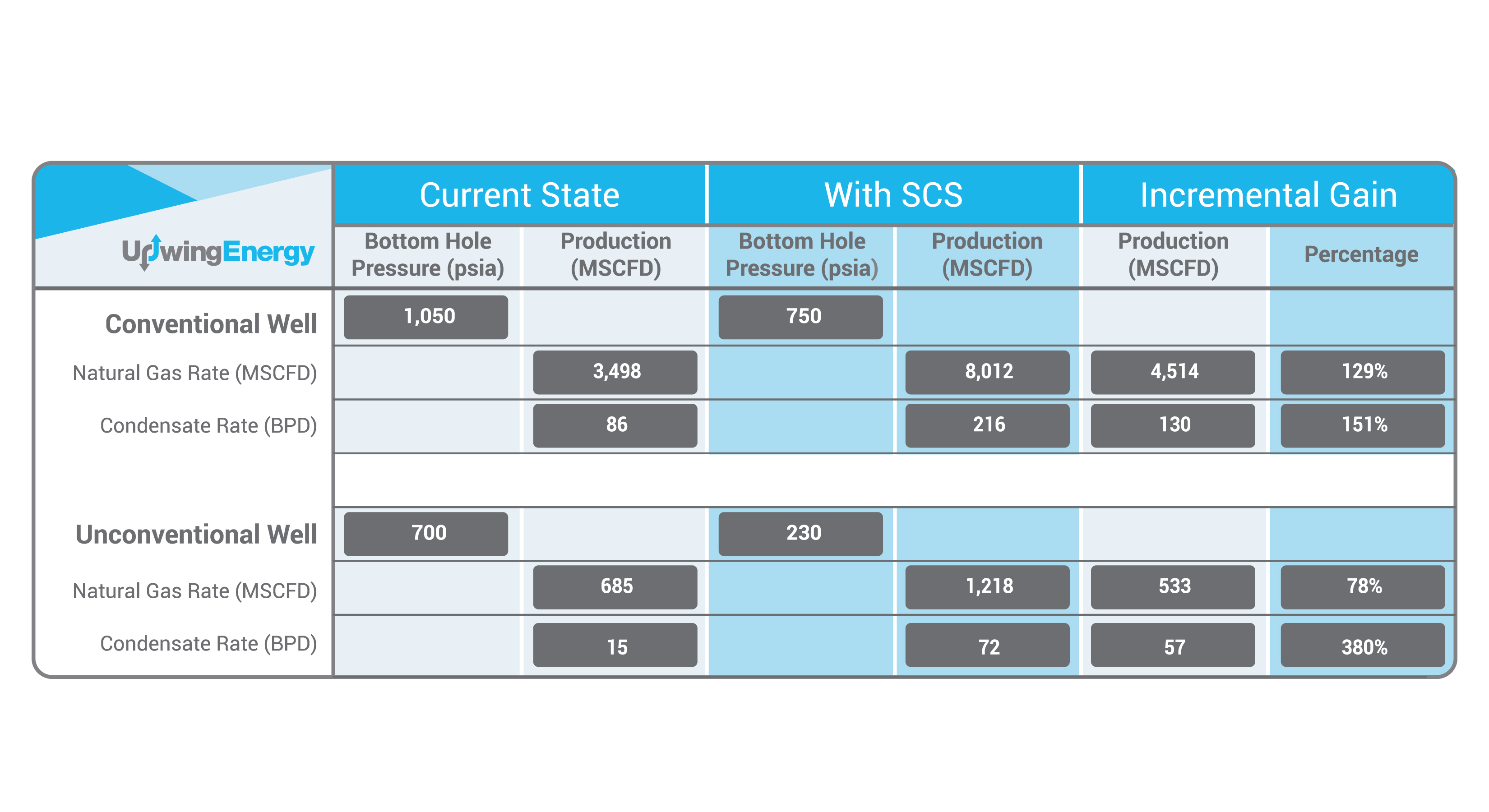

As Upwing continues with its trials, the results are being verified with comprehensive in-house models that incorporate the SCS tool, reservoir, wellbore and top-side equipment. For conventional reservoirs, these modeling tools can predict results fairly closely. For the next trials coming up in a conventional gas well, Upwing predicts a more than 62% incremental increase in gas and NGL production and an over 60% incremental increase in condensate production.

Simulations have been conducted along with feasibility studies for wells that have significant production up to 53 MMscf/d. Wells evaluated to date include the Norwegian Continental Shelf, North Africa and onshore and offshore Australia, all showing significant positive results with the SCS with up to and more than 100% incremental increase of production of gas, NGL and condensate.

With conventional wells, Upwing’s models can accurately predict the production increases and reservoir response achieved by the SCS. With unconventional wells, the company can currently predict liquid unloading and production increases but not ultimate hydrocarbon recovery with SCS.

Upwing is looking to partner with universities in the U.S. to develop a way to model the effects of the reservoir behavior with the SCS in unconventional gas wells. It is simple to deploy the SCS and recognize the incremental production improvement, but it is necessary to understand the reservoir behavior to duplicate results and develop a reliable prediction tool that will enable operators to construct their economic models for unconventional shale gas wells.

In short, artificial lift is underused in gas wells. This means both conventional and unconventional gas wells are too often abandoned before reaching their full potential. Using advanced magnetic technologies downhole, Upwing’s SCS offers potential for artificial lift to play a transformational role in boosting revenues from gas wells.

Recommended Reading

NOD Approves Start-up for Aker BP’s Hanz Project

2024-02-27 - Aker BP expects production on the North Sea subsea tieback to begin production during the first quarter.

Texas Earthquake Could Further Restrict Oil Companies' Saltwater Disposal Options

2024-04-12 - The quake was the largest yet in the Stanton Seismic Response Area in the Permian Basin, where regulators were already monitoring seismic activity linked to disposal of saltwater, a natural byproduct of oil and gas production.

Trio Petroleum to Increase Monterey County Oil Production

2024-04-15 - Trio Petroleum’s HH-1 well in McCool Ranch and the HV-3A well in the Presidents Field collectively produce about 75 bbl/d.

TotalEnergies Starts Production at Akpo West Offshore Nigeria

2024-02-07 - Subsea tieback expected to add 14,000 bbl/d of condensate by mid-year, and up to 4 MMcm/d of gas by 2028.

E&P Highlights: Feb. 5, 2024

2024-02-05 - Here’s a roundup of the latest E&P headlines, including an update on Enauta’s Atlanta Phase 1 project.