Often called the world’s most travelled refinery, Imperial Oil's Strathcona refinery has made its way through hill and valley, war and peace, and through the ebbs and flows of Canada’s oil industry. (Source: Imperial Oil Ltd.)

Imperial Oil Ltd. plans to invest CA$720 million (US$560 million) to advance construction of Canada’s largest renewable diesel facility.

Site preparation and initial construction are underway at Imperial’s 200,000 bbl/d capacity Strathcona refinery near Edmonton, the company announced Jan. 26 in a press release.

The facility will produce over 1 billion liters per year or 20,000 bbl/d of renewable diesel—primarily from locally sourced feedstocks—when it commences operations in 2025. The project will generate around 600 direct construction jobs, along with hundreds more through investments by business partners. Regulatory approval is expected over the near term.

Once in production, the facility “could help reduce greenhouse gas emissions in the Canadian transportation sector by about 3 million metric tons per year, as determined in accordance with Canada’s Clean Fuel Regulation,” according to Imperial, the largest petroleum refiner in Canada.

Significant amounts of renewable diesel from Strathcona will supply British Columbia and support the province’s plan to lower carbon emissions. Imperial also looks to utilize renewable diesel in its operations as part of its emissions reduction plans, the company said.

Support from the province of British Columbia

Imperial’s Strathcona refinery has been in operation in Canada for over 70 years. The refinery is responsible for around 30% of Western Canada’s refining capacity, according to documents on the Alberta-based company’s website.

The renewable diesel project was first introduced in August 2021. British Columbia has supported the project through a Part 3 agreement under the province’s low carbon fuel standard.

“Imperial supports Canada’s vision for a lower-emission future,” Imperial chairman, president and CEO Brad Corson said in the release.

Imperial’s renewable diesel facility will use low-carbon hydrogen produced with carbon capture and storage (CCS) technology. Imperial has entered into a deal with Air Products for low-carbon hydrogen supply and is developing deals with other third parties for biofeedstock supply.

Eventually, the low-carbon hydrogen and biofeedstock will be combined with a proprietary catalyst to produce premium lower-emission diesel fuel and reduce GHG emissions relative to conventional fuels.

Recommended Reading

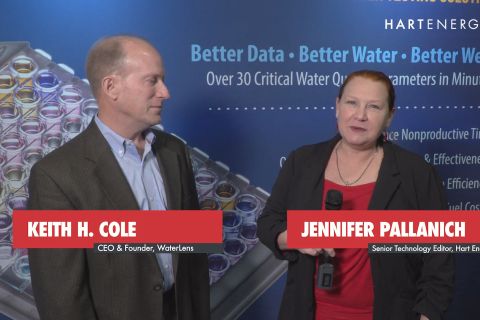

Exclusive: Calling on Automation to Help with Handling Produced Water

2024-03-10 - Water testing and real-time data can help automate decisions to handle produced water.

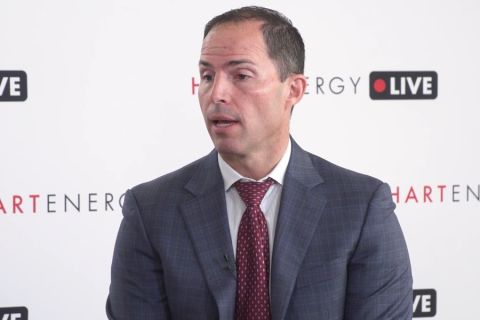

Exclusive: Chevron New Energies' Bayou Bend Strengthens CCUS Growth

2024-02-21 - In this Hart Energy LIVE Exclusive interview, Chris Powers, Chevron New Energies' vice president of CCUS, gives an overview of the company's CCS/CCUS activity and talks about the potential and challenges of it onshore-offshore Bayou Bend project.

Exclusive: As AI Evolves, Energy Evolving With It

2024-02-22 - In this Hart Energy LIVE Exclusive interview, Hart Energy's Jordan Blum asks 4cast's COO Andrew Muñoz about how AI is changing the energy industry—especially in the oilfield.

Exclusive: Liberty CEO Says World Needs to Get 'Energy Sober'

2024-04-02 - More money for the energy transition isn’t meaningfully moving how energy is being produced and fossile fuels will continue to dominate, Liberty Energy Chairman and CEO Christ Wright said.

Chesapeake, Awaiting FTC's OK, Plots Southwestern Integration

2024-04-01 - While the Federal Trade Commission reviews Chesapeake Energy's $7.4 billion deal for Southwestern Energy, the two companies are already aligning organizational design, work practices and processes and data infrastructure while waiting for federal approvals, COO Josh Viets told Hart Energy.