(Source: Shutterstock.com)

In the mid-1970s, conventional wisdom said there was about 20 years’ worth of recoverable oil left in basins like the Permian Basin. They knew much more was there—it just wasn’t economic to produce.

Forty years later—in 2015-19—that area, among others in the U.S., was producing far more oil than ever, thanks to staggering advances in technology, mostly in drilling and completions.

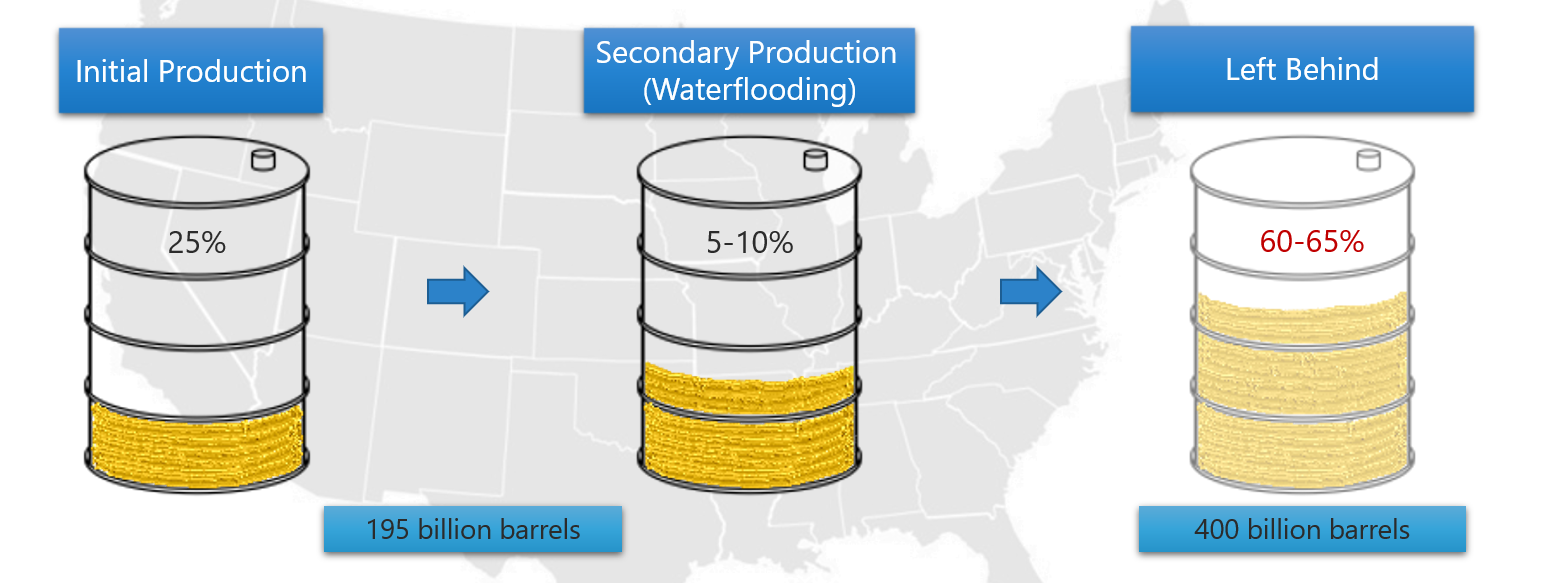

Even so, the industry is still leaving more oil in the ground than it can produce economically. Conventional production only gets about 35% of available oil, even with EOR. The shale plays, which are mostly responsible for recent increases in overall production, yield only about 8% of their oil under current methods.

The result is that approximately 400 billion barrels of oil are still available in existing wells, without ever drilling any new ones—if new, economic, recovery methods could be found.

With price cycles booming and busting at a rate that makes a price chart resemble a radio wave, E&P companies are scrambling to find and use every efficiency possible in order to stay profitable. More leasing and drilling is the conventional road to production increases, but investing millions in the process is becoming harder to justify.

Most current recovery enhancement systems arrive dragging behind them price tags of $10-$80/bbl. That includes extensive costs for infrastructure such as pipelines, injection wells (even if converting production wells, there is a cost), chemicals and more.

Doubling the economic production from existing wells—even longstanding ones—is now proving possible by the seemingly simple act of analyzing and controlling wettability, at costs as low as $4 per additional barrel produced. This can have the effect of reducing the break-even oil price by $10/bbl.

After years of R&D, ESal is now releasing to the industry a system designed to do exactly that.

The Science of Salinity and Wettability

The journey to unlocking the secrets of wettability started with the surprise discovery that conventional wisdom on the topic was incomplete at best, and wrong at its base.

Geoffrey Thyne, PhD, one of ESal’s founders, had spent years studying the relationship between salinity and recovery. The intent was to prove that reducing salinity would release more oil. Finally, Thyne concluded that salinity by itself had little direct effect on production, but did influence another factor that was a vital key to recovery: wettability.

Further investigation led to the realization that it would be better to discard the old ideas of the relationship of wettability to production, and to begin extensive development and testing from the ground up to deliver new answers. Thus came the formation of ESal in 2012.

Wettability studies go back to the 1950s, when the industry began to realize the significant impact wettability had on production. Actually, wettability testing goes back to Roman times. Unfortunately, both the Romans and 1950s engineers were limited by the technology of their day. Today, wettability testing can reach deeper and wider than ever before, giving precise data on what the best wettability is and how to achieve it in every formation. Today’s in-depth data also reveals that flooding with the wrong water chemistry can actually do extensive damage to the productivity of the reservoir.

Why does it matter? A brief definition says wettability “describes the relative preference of one fluid to coat or adhere to the grains, cementing material, and/or rock matrix with respect to all other fluids present in the pore space.” Rocks can range from strongly water wet to strongly oil wet, and all stops in between. (Scott M. Frailey)

During the research phase, ESal developed methodology designed to determine the optimal wettability of a reservoir in just a few weeks—much faster than previous technology could manage. Testing hundreds of formations over several years led to the discovery that neutral wettability—equally water wet and oil wet—brings maximum production. This lets both oil and water flow from the formation with equal ease.

It became clear that formations producing 8-10 barrels of water for every barrel of oil don’t actually have a water problem—they have a wettability problem. When the formation is preferentially water wet, it releases more water than oil. ESal now knew how to make seemingly small changes, without using chemicals, which would boost the oil percentage in the production flow.

Salinity plays a major part in wettability, but so do other factors. Readjusting the mix of produced and fresh water injected in a waterflood in order to affect salinity is often the first step in boosting production. ESal’s testing of each formation—because no two reservoirs’ wettability is the same—can inform other water changes, allowing a well to produce at least as much oil in the near future as it has produced in its entire history, no matter the age of the well.

Needless to say, adjusting wettability at the start would provide greater production for the entire life of the well.

In the Field

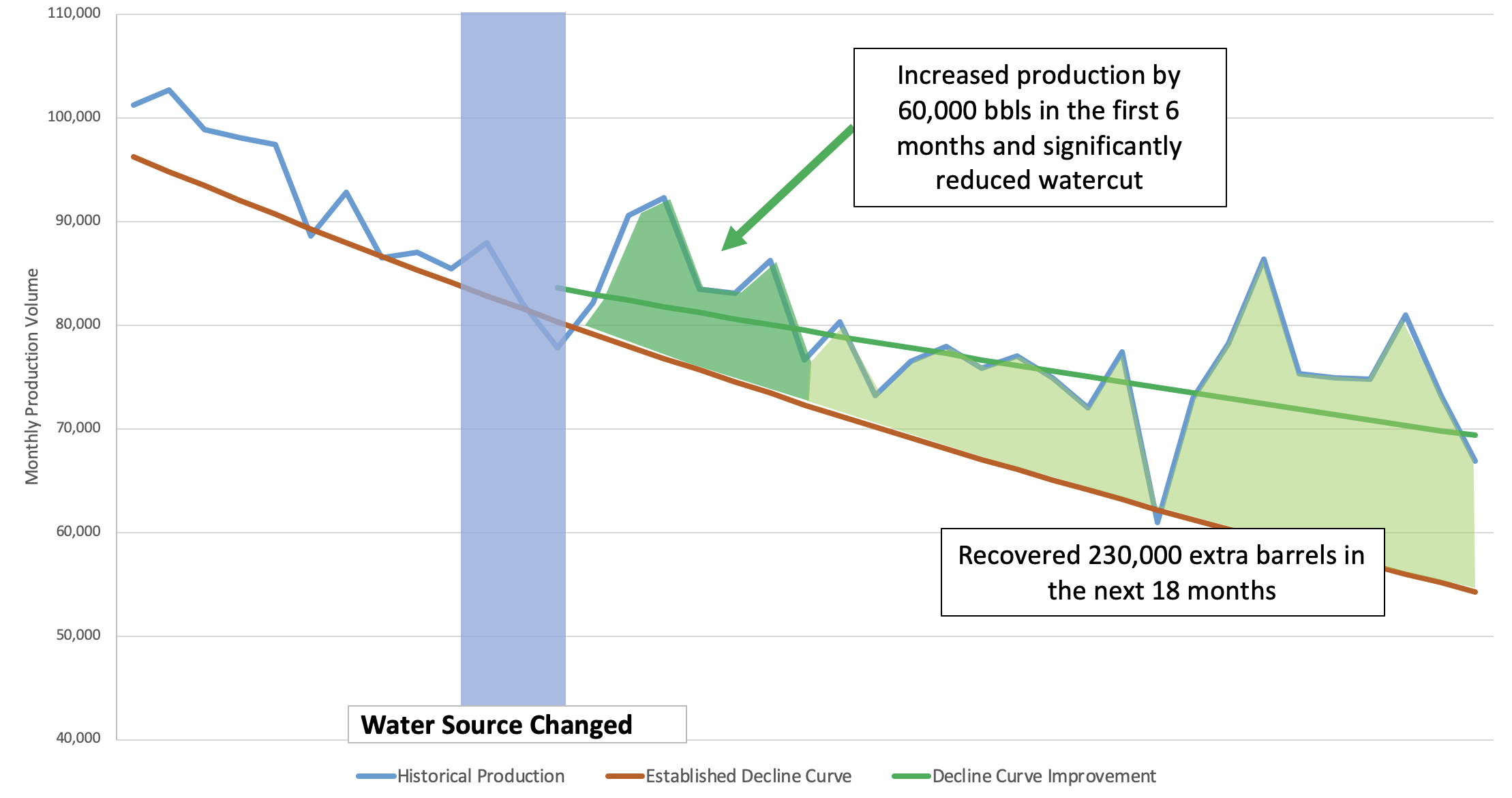

A waterflood field with 30 injection wells and 30 producing wells had a steep secondary decline rate with an increasing water cut. ESal tested rock, water and oil samples from the field for approximately four weeks in order to understand and predict the proper wettability alteration. Tests revealed that water from a different source would lead to production increases.

Because of well communication times, the first predicted production improvements after injection started began about six months later. During the 24 months following observation of the initial improvements, the producer saw the following changes:

- Production increased by 16.28%, from 2,595 bbl/d of oil to 3,017 bbl/d of oil establishing a more favorable decline rate, an increase that continues to this day;

- The increasing water cut stabilized;

- Wells produced extra 60,000 bbl of oil in six months;

- The field produced 290,000 total extra barrels of oil two years after wettability improvement;

- Project paid for itself in eight months and established multidecade-long increased profits; and

- Producer established new decline curve improving EUR projections and increased reserves.

Based on the new established decline curve and economic projections, the operator rebooked reserves, reduced production costs and maximized efficiency of oil recovery in the field.

New expectations for the remaining economic life of the field are that improving wettability will:

- Unlock a total of 4,994,000 previously inaccessible barrels of oil;

- Realize a total of $102 million ($40 realized WTI) in additional pre-tax profit, quarter of which comes from field life extension;

- Extend field life by 11 years; and

- Increase field value by $45 million.

ESal typically charges $1-$3 per additional recovered barrel after production improvement is observed in a field.

Conclusion

In the field example above, the E&P company dramatically increased reserves and reduced operating costs. This combination has been shown to lower the breakeven point by as much as $10/bbl, a breakthrough long awaited by producers riding out the whipsawing of supply-demand changes in current markets.

Based on national numbers regarding current production and proven reserves, correcting wettability would have a staggering effect on the U.S. oil industry as a whole.

ESal’s research shows that, currently, 60% of U.S. formations would benefit from wettability improvements, which would lead to production of an additional 96 billion barrels over 30 years, producing more than $1 trillion in profit, depending on price fluctuations. This would involve much less capex than drilling enough new wells to reach this much oil, and it would improve decline curves over the long haul.

By increasing the oil cut, there would be much less produced water going to saltwater disposal wells, which would reduce disposal costs and effects on the environment.

In a time when technological advancements are changing the way the world does almost everything, it is not surprising that technology could transform EOR. What does come as a shock is that this production technology seems so simple and almost obvious. But because it involved a complete rethinking of wettability, it took a happy accident and an open mind to open the doors to discovery.

Ft. Worth, Texas-based ESal has developed a revolutionary method to change reservoir wettability by optimizing the salinity of injected water. This unique method can be applied in all three phases of oil field production at much lower costs than all other currently available techniques and without using chemicals. Visit their website at: esalinity.com

About the Author:

Salem Thyne serves as CEO of ESal. Thyne is an internationally recognized expert in chemical and energy operations with 23 years of experience in corporate management, regulatory compliance and operations. He joined ESal in 2017.

Recommended Reading

TPG Adds Lebovitz as Head of Infrastructure for Climate Investing Platform

2024-02-07 - TPG Rise Climate was launched in 2021 to make investments across asset classes in climate solutions globally.

Air Products Sees $15B Hydrogen, Energy Transition Project Backlog

2024-02-07 - Pennsylvania-headquartered Air Products has eight hydrogen projects underway and is targeting an IRR of more than 10%.

NGL Growth Leads Enterprise Product Partners to Strong Fourth Quarter

2024-02-02 - Enterprise Product Partners executives are still waiting to receive final federal approval to go ahead with the company’s Sea Port Terminal Project.

Sherrill to Lead HEP’s Low Carbon Solutions Division

2024-02-06 - Richard Sherill will serve as president of Howard Energy Partners’ low carbon solutions division, while also serving on Talos Energy’s board.

Magnolia Appoints David Khani to Board

2024-02-08 - David Khani’s appointment to Magnolia Oil & Gas’ board as an independent director brings the board’s size to eight members.