Eagle Ford Shale frac operations in DeWitt County, Texas. (Source: Tom Fox/Hart Energy)

Each year innovators in the hydraulic fracturing space find new ways to push the industry forward, improving the efficiency of operations while lowering costs. Hydraulic fracturing experts will gather Feb. 4-6 at the Society of Petroleum Engineers’ (SPE) Hydraulic Fracturing Technology Conference and Exhibition in Houston to share knowledge and discuss the industry’s challenges, and many companies will feature their newest and most impressive technologies. The following is a sampling of the latest products and services that will be showcased at the conference.

[Editor’s note: The copy herein is contributed from service companies and does not reflect the opinions of Hart Energy. This story originally appeared in the January 2020 edition of E&P. Subscribe to the magazine here.]

Microproppant improves production

CARBO’s NANOMITE microproppant is a fraction of the size of the smallest proppant commonly deployed and is offered in both ceramic and sand versions: NANOMITE C and NANOMITE S. This cost-effective offering is for operators experiencing difficulty with proppant placement, elevated treatment pressure and early screenouts during treatment. Traditional proppant is too large to fit into a complex fracture network’s microfractures, and its transport characteristics limit how far it travels into the area. NANOMITE C’s smallest particles are more than five times smaller than the smallest particles in 100 mesh frac sand. This allows the particles to prop open even the narrowest secondary fractures and microfractures experienced in complex fracture networks. NANOMITE ensures operators’ microfractures contribute to production, increases propped reservoir volume, diminishes treatment pressure and ensures long-term well productivity for operators. carboceramics.com

Company highlights proppant data, features resin-coated frac sand

Covia provides oil and gas completions solutions spanning any well environment in all major basins. At the SPE Hydraulic Fracturing Technology Conference, the company will showcase the value of an engineered approach to proppant selection, the incremental benefits of resin-coated sands and a comprehensive mineto- wellhead, full service supply chain. Testing and field data indicate that the enhanced physical and chemical properties found in Tier 1 sands offer higher oil production when compared to completions using cheaper Tier 2 sands in high-stress basins. Covia is introducing Backstop, the Permian’s dedicated proppant flowback sand. Backstop is a resin-coated in-basin frac sand that ensures proppant stays in the well where it belongs. coviacorp.com

Smaller footprint, higher horsepower of frac pump decrease costs

Cudd’s new Q-3000 frac pumps deliver maximum efficiency, durability and lower operating costs, requiring a smaller footprint compared to a conventional lower-horsepower fleet. These powerful units are the first final Tier 4 emissions-compliant, diesel-powered 3,000-bottomhole-pressure frac units in the industry. They provide more than 2,800 hydraulic horsepower (hhp) at pressures up to 14,000 psi (higher pressures available with 4.5-in. plungers). The 550-gal fuel capacity enables extended pumping operations with higher fuel efficiency and power density per spread. The Q-3000 pumps include an exhaust gas recirculation system that reduces emissions without compromising performance and does not require diesel exhaust fluid or diesel particulate filters. A smaller footprint with increased horsepower means less nonproductive time and improved safety, all of which contribute to a lower operational cost. cuddenergyservices.com

Valve addresses operational challenges of diverter

The impact of pumping large volumes of diverter through stimulation pumping equipment is a wellknown industry challenge. DiverterPlus and National Oilwell Varco (NOV) have coordinated their efforts to minimize or eliminate the accelerated wear and potential damage that can occur when particulate diverter embeds into the valve insert. Through manipulation of the polymers’ mechanical properties and geometries via new manufacturing techniques of its Div+ line of particulate diverters, DiverterPlus has been able to eliminate the need for additional equipment in aggressive diversion deployments. Utilizing NOV’s Blue Thunder valve and the additional data gained from cooperative development, the insert compound used with the valve is highly resistant to wear and exhibits none of the problematic embedment issues traditionally associated with large particle diverters. The combined system eliminates downtime risk and potentially costly maintenance, allowing pressure pumping operations to continue at their maximum efficiency. diverterplus.com, nov.com

Solid expandable liners enhance operations

Enventure Global Technology Inc. is a provider of solid expandable technologies for the energy industry. Solid expandable technology can be used for multistage fracturing in unlimited zones or sections and provides a large inside diameter to accommodate larger perforating guns and flow areas as well as larger frac volumes and rates. Solid Expandable Refrac Liners are multizone isolation completion tools that utilize solid expandable technology and elastomer technology to enhance fracturing operations. In addition, ReFrac products support any type of perforating, plug and fracturing program from conventional-shaped charge perforation on coil to pumpdown composite plugs for isolation. These solutions allow the creation of multiple new performation and fracture intervals or zones to support refracturing programs. The newly released next-generation solid expandable refracturing liner provides operators more options when selecting mechanical zonal isolation techniques. enventuregt.com

Importance of tank monitoring and asset tracking

Using measurement tools in storage and transportation tanks has a positive effect on the efficiency and lifetime of chemicals and equipment. Liquid monitoring and asset tracking technology play a huge part in the monitoring of chemicals from the chemical companies to the final user and can help ensure timely delivery and real-time monitoring of quantities of chemicals contained. When selecting asset monitoring solutions, there are several main points to consider. These include looking for a range of scalable solutions with viable costs and capabilities to fit needs and budgets. It is important that the solution is tailored to a direct need. Tangible value and benefits should be aligned with a company’s operational goals and objectives. Additionally, technology options, such as satellite and cellular, should accommodate difficult transmission from remote locations. hooverferguson.com

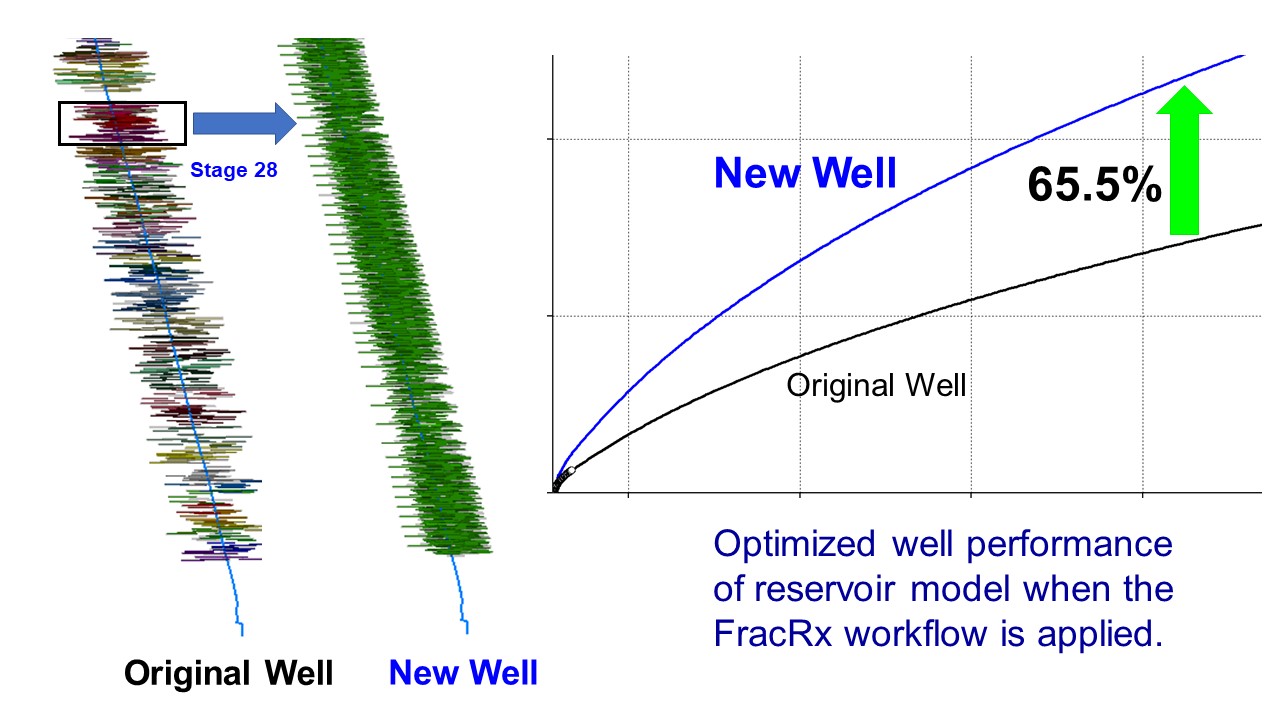

Platform uses data to help operators improve production

FracRx is the formalization of MicroSeismic Inc.’s data analytics and synthesis platform integrated with multiphysics data that show operators precisely when to start or stop fracturing in real time based on rate of return. FracRx focuses on drilling profitable wells by constructing a complete stimulated reservoir model based upon a propped and unpropped discrete fracture network, as illuminated by the monitoring data, using MicroSeismic’s technique. After building an economic model based on the operator’s cost and price decks, FracRx performs a reservoir simulation to estimate fluid volumes produced and drainage volumes achieved over time, and then it creates a financial model to estimate the most economic (greatest net present value) completion parameters. The platform offers a complete description and map of the treated reservoir, including drainage volume, during the frac by delivering the stage-by-stage answers that engineers want and need to improve production and increase asset value while pumping. microseismic.com

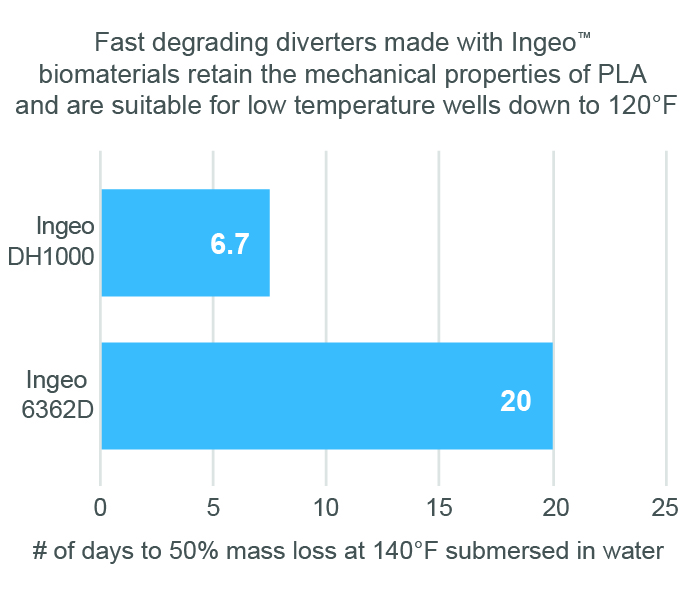

Diverter hydrolyzes faster in lower temps

Historically, degradable polylactide (PLA) diverter functionality has been limited to wells greater than 150 F. While PLA-based products could adequately divert below 150 F, they were slow to hydrolyze at these cooler well temperatures. Commercial alternatives that would hydrolyze faster at low temperatures tended to present handling issues, sometimes requiring refrigerated storage. Developed with A. Schulman, NatureWorks’ Ingeo DH1000 hydrolyzes up to four times faster at downhole temperatures in the previously unmet range of 120 F to 150 F while retaining the inherent mechanical properties of PLA. In addition, DH1000 is delivered to the well site in pails or bags and requires no special handling. Available in formulations of varying particle sizes, these diverters can be used in near-wellbore as well as far-field applications where they can be employed to minimize the incidence of frac hits. Commercially available in 2019, DH1000 has been placed in more than 75 wells across the Permian Basin as well as several international trials. natureworksllc.com

Proppant delivery system lowers trucking costs

Proppant Express Investments LLC (PropX) is a privately held company headquartered in Denver. PropX is a last mile containerized system for frac proppant delivery from mine or transload terminal to well sites. The system is designed to lower last-mile trucking costs, end truck traffic, eliminate demurrage, offer more flexible maximized load volume and produce less dust and noise than incumbent methods, as well as allow some of the highest throughput frac operations in the world (greater than 9 MMlb/d per crew in several instances). The ability to unload and load sand containers in less than 10 minutes (versus 45 minutes for the same proppant mass with pneumatic transfer) dramatically reduces the truck staging problem and demurrage fees charged by the truckers while standing by waiting on their turn to unload. PropX deliveries incorporate a smartphone and desktop app, which provides fast, easy ordering of sand, trackability of loads by driver from terminal to well site, sand inventory at the well site and frac stage report summaries. propx.com

Silica dust engineering system designed for hydraulic fracturing

Sierra Dust Control LLC’s vacuum-based system uses containment that has proven 100% effective in all weather types and equipment configurations, including box and silo sand delivery systems. Results are accomplished with zero impediment on well completion operations or personnel. OSHA requires continued exposure monitoring for levels above 25 μg/cu. m. Under a new rule commencing June 23, 2021, hydraulic fracturing work sites must implement engineering controls that maintain free silica dust exposures below the permissible exposure limit. sierradustcontrol.com

New service measures frac performance in real time through wireline

To improve stimulation and completion designs and deal with the growing concern of interwell communications, operators need data to gain insight into reservoirs. Evaluating stimulation performance in real time and quantitatively measuring the extent of fractures are the biggest tasks in shale play development. According to Silixa, it has released the first fiber-optic wireline-deployed hydraulic fracture monitoring service with Carina XwellXpress. The service allows the realtime monitoring of the buildup of poro-elastic strain and identification of frac hits while accurately co-locating microseismic events and collecting high-quality seismic data. This enables operators to optimize well spacing and change frac designs on the fly to improve production and reduce overall completion costs. The system is easily deployable using conventional wireline pumpdown or tractor technology. A number of cables can be deployed or redeployed during the frac program delivering an accurate surface visualization of the development of the fracture network as the frac program develops. silixa.com

Shorter pump trucks featured in new fleet

USWS will be unveiling the next-generation fleet in the first quarter of 2020. The latest design has reduced the overall length of the pump trucks by 23% from 48 ft to 36.9 ft. The reduction in the length of the pump trailer was achieved through the development of the Power Cube System, which allows the transformer and electric motor controls to be housed together. USWS sources components to boost efficiency and life of the equipment and has upgraded the power end, which has a more robust construction to stand up to the industry’s harsh working environments. Another upgrade to the next-generation Clean Fleet is a packing lubrication system that utilizes multiple sensors to lubricate more efficiently. This system will improve packing life, reduce waste and increase operational efficiencies. In addition, this next-generation fleet will have a design to fit oil lubrication, which will reduce the cleanup associated with grease-based systems. uswellservices.com

Recommended Reading

Report: Freeport LNG Hits Sixth Day of Dwindling Gas Consumption

2024-04-17 - With Freeport LNG operating at a fraction of its full capacity, natural gas futures have fallen following a short rally the week before.

Permian NatGas Hits 15-month Low as Negative Prices Linger

2024-04-16 - Prices at the Waha Hub in West Texas closed at negative $2.99/MMBtu on April 15, its lowest since December 2022.

BP Starts Oil Production at New Offshore Platform in Azerbaijan

2024-04-16 - Azeri Central East offshore platform is the seventh oil platform installed in the Azeri-Chirag-Gunashli field in the Caspian Sea.

US Could Release More SPR Oil to Keep Gas Prices Low, Senior White House Adviser Says

2024-04-16 - White House senior adviser John Podesta stopped short of saying there would be a release from the Strategic Petroleum Reserve any time soon at an industry conference on April 16.

Core Scientific to Expand its Texas Bitcoin Mining Center

2024-04-16 - Core Scientific said its Denton, Texas, data center currently operates 125 megawatts of bitcoin mining with total contracted power of approximately 300 MW.