According to the U.S. Environmental Protection Agency’s (EPA) “Inventory of U.S. Greenhouse Gas Emissions and Sinks” report, methane accounts for about 10% of U.S. greenhouse gas (GHG) emissions. Of this, one-quarter is from the natural gas industry. Expressed as a percent of natural gas production, this equates to 1.3% of production. While other studies have suggested much higher emission levels (some as high as 7.9%), the most recent and most comprehensive non-EPA study found emissions only slightly higher at 1.7% (the paper tabulates emissions for both oil and natural gas systems at 2.3% of gas production. ICF estimates that the natural gas portion equates to 1.7% of emissions).

ICF’s services for measurement and mitigation of methane emissions from the oil and gas industry have included work for the industry, regulators and nongovernmental organizations ranging from policy analysis and development to direct support for industry operations. Over the last five to 10 years, the company has seen an increasing focus on methane emissions from these industries for several reasons.

Among those is that the climate-forcing effect of methane is greater than that of CO2. The global warming potential (GWP) describes the ratio of methane equivalent to 1 ton of CO2 and can range from 34 to 86, depending on the timescale being considered. On the positive side, this means that reducing 1 ton of methane is equivalent to reducing 34 to 86 tons of CO2. In addition, there are available methane-reduction technologies for most of the emission sources.

When methane emissions can be captured and sold, the value of the gas can offset the cost in some cases.

Tracking emissions

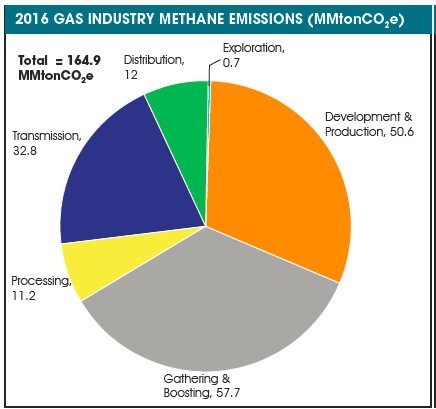

On the other hand, reducing methane emissions is complicated by the fact that the natural gas industry is actually several different industries with different types of emission sources and ownership and regulatory structures. The EPA inventory includes more than 100 different industry segment/ emission source categories. Figure 1 shows the EPA estimate of emissions in the various industry segments. Gathering and boosting is the largest, followed closely by development and production, and then transmission and storage.

Methane emissions from oil and gas operations have declined significantly since the EPA started tracking them, decreasing from almost 200 MMtonCO2e in 1990 to 164 MMtonCO2e in 2016. (Editor’s note: According to the EPA, the unit CO2e represents an amount of GHG whose atmospheric impact has been standardized to that of one unit mass of CO2, based on the GWP of the gas.) Moreover, natural gas production has increased significantly during that same period, so emissions per unit of production have been declining continuously, falling by 45% from 9 kg CO2e/Mcf in 1990 to 5 kg CO2e/Mcf in 2016 (Figure 2).

There are several reasons for this continuing decline. As equipment is replaced and new equipment comes online, the new equipment is typically cleaner and more efficient.

In addition, the industry has made significant voluntary reductions, including those made in cooperation with the U.S. EPA Natural Gas STAR program, which has reported more than 28 Bcm (1 Tcf) of methane reductions.

In recent years federal regulation (e.g., New Source Performance Standards) and state regulation (e.g., Colorado Regulation 7 and Pennsylvania GP-5) also have resulted in reductions.

Opportunities for reduction

Nevertheless, there are still opportunities for further reductions. In 2014 ICF completed a study that quantified the opportunities and costs for methane reductions in the natural gas industry. Since that time the quantification of baseline emissions technologies has improved, new regulations have changed the baseline, mitigation technology costs have declined and new technologies have been developed. Although the specific results of the study could bear updating, they are useful for an initial survey of current opportunities for reductions.

Some of the opportunities, while still cost-effective, are no longer as large because they have now been implemented at many facilities or are now required by regulation. For example:

- Emissions from well completion for hydraulic fracturing are regulated to a high degree of reduction;

- Many high bleed pneumatic devices have been replaced and low bleed pneumatics are now required for many applications;

- Instrument air is required in certain applications as a replacement for gaspowered equipment;

- Scheduled rod packing replacement is now required for reciprocating compressors in some applications; and

- Wet seal compressor emissions are lower than previously thought.

Management opportunities

Although many of these opportunities might be smaller than projected a few years ago, some of them still might be attractive. In addition, there are other opportunities that have changed less and present good possibilities. One is leak detection and repair programs and control of nonstandard emission events. Structured periodic inspection and leak detection programs are important to maintaining good equipment performance, identifying equipment problems that create emissions and avoiding intermittent malfunctions that can result in large emissions.

Another such opportunity might be better control of liquids unloading. Well venting to control liquids is a potentially large source of emissions. There are a variety of alternative measures depending on the age and other characteristics of a well, so there is no one solution, but lower emitting solutions exist and should be pursued. New approaches might be required for horizontal wells as they age.

A third opportunity could be replacement of pneumatic pumps. Electric pumps or instrument air can be highly cost-effective alternatives where electricity is available either from the grid or onsite gas- or solar-powered generators.

Vapor recovery from tanks is still an important option even though more tanks have been regulated in recent years. Although the emissions are small in the overall inventory, reduction of methane from the natural gas industries can be a cost-effective option.

Finally, flaring of stranded gas from oil wells could be an opportunity for implementation. Even as flaring is being reduced via improved infrastructure and due to regulation, there are still opportunities to reduce flaring through onsite gas use and/or capturing the gas via CNG or LNG.

References available.

Contact Brian Walzel for more information at bwalzel@hartenergy.com.

Recommended Reading

Duke Energy Appoints Harry Sideris to President

2024-03-15 - Steve Young, executive vice president and chief commercial officer, will retire from Duke Energy on June 30.

Hess Corp. Boosts Bakken Output, Drilling Ahead of Chevron Merger

2024-01-31 - Hess Corp. increased its drilling activity and output from the Bakken play of North Dakota during the fourth quarter, the E&P reported in its latest earnings.

The OGInterview: Petrie Partners a Big Deal Among Investment Banks

2024-02-01 - In this OGInterview, Hart Energy's Chris Mathews sat down with Petrie Partners—perhaps not the biggest or flashiest investment bank around, but after over two decades, the firm has been around the block more than most.

Some Payne, But Mostly Gain for H&P in Q4 2023

2024-01-31 - Helmerich & Payne’s revenue grew internationally and in North America but declined in the Gulf of Mexico compared to the previous quarter.

Petrie Partners: A Small Wonder

2024-02-01 - Petrie Partners may not be the biggest or flashiest investment bank on the block, but after over two decades, its executives have been around the block more than most.