(Source: Yesenia Rodriguez/marcmorrison.com)

[Editor's note: A version of this story appears in the September 2020 edition of E&P Plus. It was originally published Aug. 31, 2020. Subscribe to the magazine here.]

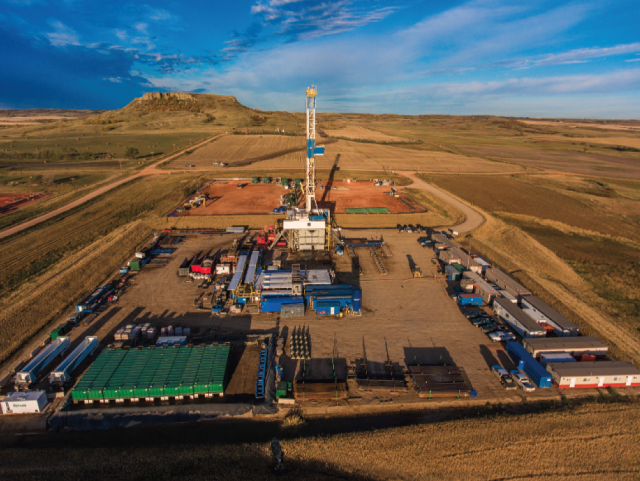

Hybrid mud logging is a major step change in providing quantitative data in near-real time without increasing personnel. Formation evaluation at the wellsite was initially carried out by geologists examining cuttings and formation gas collected from the mud stream and “lagged” to bit depth, a practice known as mud logging or surface logging. Over the years, technological advances and economic viability allowed ever more complex downhole measurement tools to be created and run. These MWD and LWD tools determine several formation properties and have become uniquely associated with formation evaluation.

In today’s business climate, upstream oil and gas companies are increasingly focused on capital efficiency and return on investment (ROI). Delivery of an acceptable ROI to private and public investors is currently challenging in unconventional plays. However, these challenges also apply offshore with its high cost operations, the focus on trimming budgets, reduction of nonproductive time (NPT) and risk, and getting the best data at the best price.

By reinventing mud logging through the development of robotic solutions and advanced software for the collection and analysis of drilled cuttings, including real-time geochemistry at the well site, Diversified Well Logging (DWL) is providing a tool to help operators achieve better capital efficiency and ROI. As a result, high-resolution quantitative data at low risk and cost are available for geologists and engineers, meaning that formation evaluation can return to the surface.

Reinventing mud logging

Reinvention of mud logging was necessary to meet the need for quantitative data on depth while also being representative of the interval sampled at a higher resolution. The technology also needed the same number of people at the well site and to meet the requirement to provide more value and reduce risk. The result of these needs is hybrid mud logging (HML).

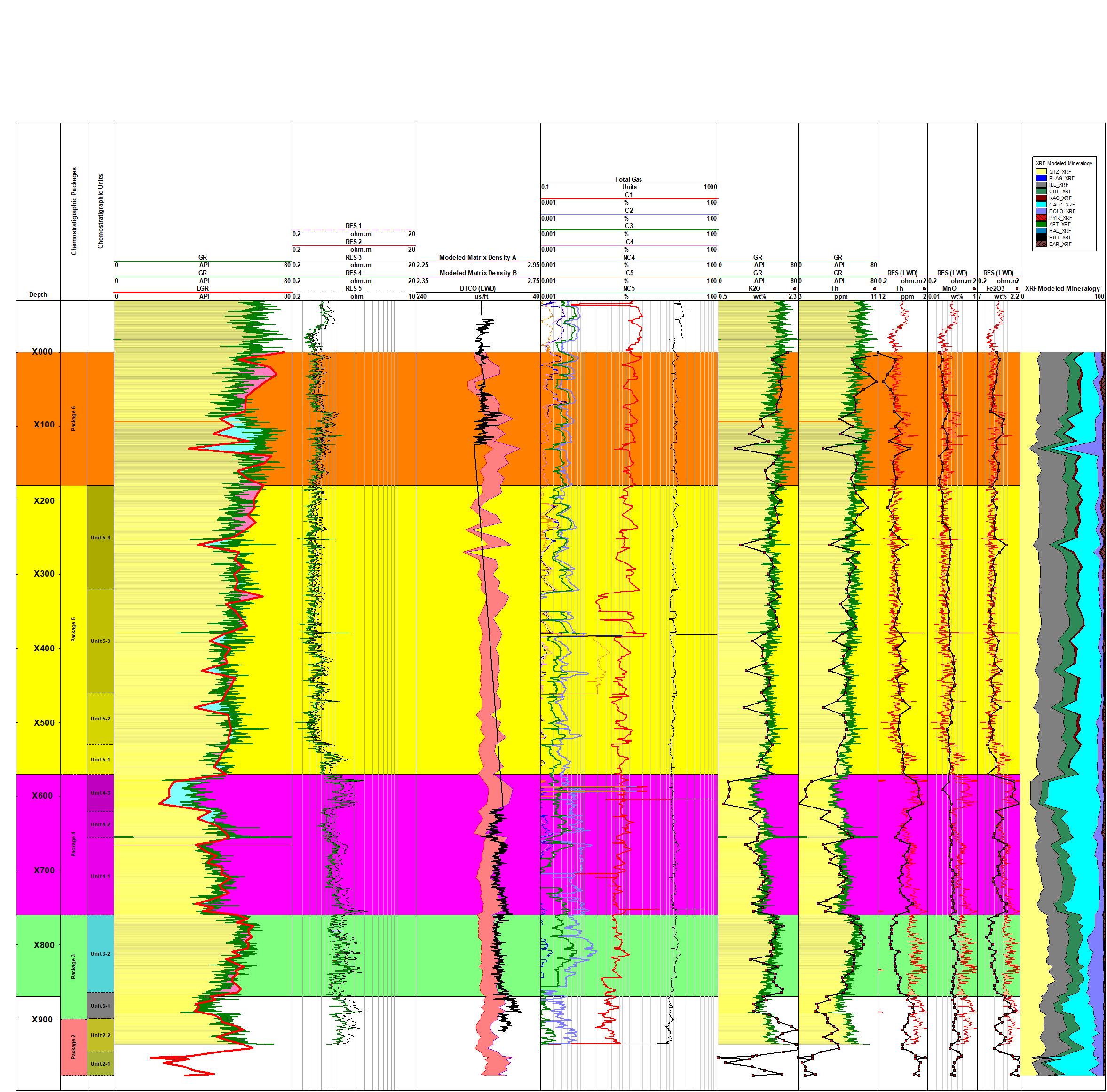

Using drill cuttings and benchtop portable X-Ray fluorescence (XRF) instruments, rigorous laboratory quality control procedures can be applied to provide near-real-time elemental rock measurements. Combined with drilling data, formation gas and artificial intelligence (AI) methods, including machine and deep learning, an important window into the subsurface is now available.

This evolution from qualitative sample analysis to quantitative elemental, mineralogical and chemostratigraphic interpretation allows in real or near-real-time

- Accurate stratigraphic wellbore positioning;

- Improved understanding of depositional environment and provenance;

- Improved understanding of reservoir quality;

- Facies characterization;

- Modeled mineralogy;

- Estimation of clay composition;

- Relative grain size indication;

- Cavings ID related to wellbore stability;

- Drilling hazard mitigation (chert beds);

- Integration with gas data for fluids ID, compartmentalization and connectivity;

- Quantitative formation evaluation and correlation;

- Geosteering (or elemental/ chemosteering);

- Improving drilling efficiency;

- Avoiding geohazards and reducing NPT; and

- Optimizing landing targets or casing points.

Elemental gamma ray

With real-time quality control of the samples and data, problems related to on-depth sample representation and contamination are resolved immediately at the well site rather than weeks or months later in a laboratory. To confirm that samples are on-depth, the elemental gamma ray (EGR) is calculated and compared with MWD/LWD gamma ray (GR) when available. The EGR is calculated from the elemental values of uranium, thorium and potassium derived from XRF analysis of the drilled cuttings. With case histories from many wells onshore and offshore, confidence in the EGR is high. Many case histories have shown excellent coherence with downhole GR giving operators the confidence to drill on with EGR when the MWD/LWD tool has failed.

The importance of depth control is increased when geosteering through tight target windows. Unconventional production depends on drilling long lateral wells in the right place through formations that are perceived to be relatively homogenous, with only downhole GR as the steering and formation evaluation tool. HML, EGR and GR are used as corroborative datasets for the geosteering team and, more importantly, the elemental data are used to fingerprint lithological packages allowing chemosteering.

Given the XRF provides 25 to 32 elements and an almost infinite number of elemental ratios compared to a single measurement, such as total GR, this permits differentiation of lithological packages that might appear the same for GR alone. With the high cost of LWD, realtime elemental data provide the fidelity of formation evaluation that enhances geopositioning, detects and avoids geohazards, and provides a rich source of data for cost-effective improvements in drilling and production efficiency for every well drilled.

Case History 1

Using HML’s real-time elemental data enabled an operator to successfully geo-stop a well that had faulted 200 ft out of the Austin Chalk into the overlying Anacacho Formation. The magnitude of the fault and formation dip after the fault determined it was not possible to steer the wellbore back into the target before the planned total depth of the well. With average drilling and completion costs in this area estimated to be in the $8 million to $10 million range, considerable savings were realized.

Case History 2

Expanding on the value of surface MWD and formation evaluation, and by using real-time quantitative elemental data combined with AI software, a South Texas operator was prompted to reevaluate its formation evaluation program. Where traditional mud logging was used only infrequently—one well per pad—following a trial of HML, the operator found it was able to use the data to predict hydraulic fracturing efficiency without the cost and time of running microseismic and fiber-optic measurements. The power and utility of quantitative geological data combined with innovative software led the operator to deploy HML on all wells in South Texas for 2020.

Vast amounts of information can be garnered from rocks and gas collected at the surface while drilling. XRF elemental data are used to model mineralogy, total organic carbon, matrix density and estimate parameters such as bulk density and porosity. This is all achieved without the cost and risk inherent in running downhole tools. Downhole tool acquisition costs from wireline and LWD are estimated to be in the range of $14 billion annually, according to Spears and Associates. While downhole tools can fail with loss of data, become stuck or lost in hole, elemental data from cuttings are always available for formation evaluation. With advanced software, synthetic logs can be created for advanced geological, geomechanical and petrophysical use.

Case History 3

HML was recently used in the Gulf of Mexico to identify a crucial casing point at the Cretaceous-Paleocene boundary, which marks a major pressure regression due to the presence of impact breccias and depletion. During the drilling operation, the LWD tool failed with loss of real-time sonic, resistivity and GR data over a 1,600-ft section. Confidence in the EGR and chemostratigraphic location allowed drilling to continue without tripping for a new tool. Sonic data were lost from the memory data as well.

The matrix density modeled from elemental data showed coherence with the sonic log prior to tool failure and with the new tool on the next bit run. The matrix density modeled from the elemental data filled in the missing interval. Certain elements were seen to correlate with resistivity throughout the hole section. Possible reasons for these correlations and links to factors governing pore pressure are being explored.

Next step transformation in mud logging

Higher-resolution sampling is achieved with DWL’s robotic mud logger. The Robologger can collect and store samples every 2 minutes, providing quantitative rock composition at greater depth resolution than is possible with humans. The tool provides consistent sample collection, 24/7 in all weather and lowers HSE risk and carbon footprint by reducing the number of personnel required at the well site. Current development will integrate a laser induced breakdown spectroscopy device into Robologger for real-time elemental cuttings analysis.

Drilled cuttings and mud gas provide a physical sample of the subsurface. With quantitative elemental analysis and EGR, users can be confident that the samples are on depth and representative. These two factors are one reason why the industry has historically been reluctant to utilize the full potential of drilled cuttings. With the focus on cost and reduction in risk, HML is a major step change in providing quantitative data in near-real time without increasing personnel.

With automation and robotics integrated with the power of AI and deep learning, the Robologger will be the next step transformation in mud logging by providing high-resolution, quantitative sample collection and analysis in real time with a reduction in personnel. This surface MWD provides high-resolution, quantitative data in real time at reduced risk and greater value and helps the industry achieve better capital efficiency and ROI.

Recommended Reading

Matador Resources Announces Quarterly Cash Dividend

2024-04-18 - Matador Resources’ dividend is payable on June 7 to shareholders of record by May 17.

EQT Declares Quarterly Dividend

2024-04-18 - EQT Corp.’s dividend is payable June 1 to shareholders of record by May 8.

Daniel Berenbaum Joins Bloom Energy as CFO

2024-04-17 - Berenbaum succeeds CFO Greg Cameron, who is staying with Bloom until mid-May to facilitate the transition.

Equinor Releases Overview of Share Buyback Program

2024-04-17 - Equinor said the maximum shares to be repurchased is 16.8 million, of which up to 7.4 million shares can be acquired until May 15 and up to 9.4 million shares until Jan. 15, 2025 — the program’s end date.

Mexico Pacific Appoints New CEO Bairstow

2024-04-15 - Sarah Bairstow joined Mexico Pacific Ltd. in 2019 and is assuming the CEO role following Ivan Van der Walt’s resignation.