Archer’s VIVID tool provides an approach to cement evaluation. (Source: Archer)

Ever since the drilling of what is recognized as the first commercial oil well in 1859, the problem of isolating different zones in the rock formations has been prevalent. To address the problem of unwanted water threatening that first well, a section of cast iron pipe was run in the hole, becoming in the process the first ever casing string to be set. Despite the installation of casing becoming standard procedure, however, problems with water entering the well by moving behind the casing persisted. This, in turn, gave rise to the practice of trying to fill the space between the casing and the rock formation with a bonding material or cement to stop any unwanted movement.

Theory and practice not always being in alignment, there was a need for some method of evaluating the success of the cement job. It was not until the advent of the acoustic-based cement bond log in the 1960s that the ability to directly confirm the presence of cement between casing and formation became available. This tool, still in widespread use in various forms, relies on attenuation of a transmitted acoustic pulse to infer the properties of the cement bond.

Conventional approaches

All of the currently accepted cement evaluation techniques rely on active sensing or, described differently, a stimulus is applied to the casing/cement/formation combination and the response is analyzed to draw conclusions about the quality of the bond.

The inclusion of multiple sensors, or single sensors that may be rotated circumferentially, allows a radial map of cement presence to be generated. This can confirm that cement has been placed around the casing, not leaving channels within the cement that might provide paths for fluid movement.

But these techniques, sophisticated as they have undoubtedly become, can only give the assurance that the cement is physically there. What they cannot do is detect whether the cemented barrier is actually sealing against unwanted flow. There are innumerable examples of wells that exhibit sustained annular pressure despite the recording of a “good” cement condition log either during well construction or later on in its life cycle.

The leak rate might be very small, taking hours or days to build up to an appreciable level, and for normal well operations this might very well be acceptable. When a well needs to be abandoned in perpetuity, there is no acceptable level of leakage because after the plug-and-abandonment (P&A) operation is complete, there is no going back into the well to affect a remediation. In such cases, the confirmation that the well is actually secure becomes paramount, and a metric of the performance of the cement is required rather than verifying that it is merely present.

A new direction for evaluating cement

The ultimate test of a cement barrier is whether it allows the fluid to pass. The movement of fluid along a tortuous path will result in the generation of acoustic energy, even if the rate of movement is small. This energy may be detected by a suitably designed and sensitive acoustic receiver and can be used as a definitive indicator that there is flow within the cement barrier.

Archer has developed a new generation of ultrasensitive logging instruments. Under the Acoustic Listening Platform, the VIVID sensor has been designed from the start to be sensitive to practically any frequency of sound to be found in a borehole environment and to have the lowest detection threshold available on passive acoustic sensors.

In most conventional designs, the sensor itself is housed in an oilfilled chamber for reasons of pressure compensating against hydrostatic forces due to well fluid. This results in the attenuation of acoustic signals and an increase in the minimum detectable noise level. A pressure-balanced insertion assembly allows the acoustic window of the VIVID sensors to be coupled directly to the well fluid, thereby removing a level of signal attenuation and at the same time acoustically isolating the tool body from the sensor. The end result is a measurement device with unparalleled sensitivity to direct acoustic signals that also is relatively impervious to unwanted “road noise” transmitted along the tool string body.

Rigorous testing

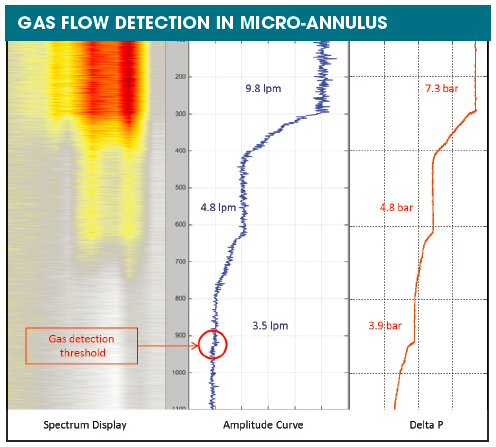

Testing of the detection range of the VIVID service was performed under controlled conditions using test cells specifically engineered to reproduce known cement defects. A micro-annulus is notoriously difficult to detect using conventional techniques and might go undetected in many cases, especially if it is a cement-to-formation micro-annulus. A test cell consisting of 7-in. tubing cemented inside 95⁄ -in. casing was made and included an engineered exterior micro-annulus. This was rigged up in such a way that a fluid, either liquid or gas, could be pumped at pressure into the annular space between tubing and casing at a variety of flow rates.

The results demonstrated the VIVID tool was able to detect water flowing in the micro-annulus down to 0.08 liter/min. The acoustic signature of gas movement in the micro-annulus was observable even at low differential pressures (2-4 bars) with rates as low as 3.5 liter/ min (metered at standard conditions).

Field-proven service

To date, 10 wells have been surveyed with the Archer VIVID Cement Performance Evaluation service. As part of the preparation for a fieldwide permanent abandonment program, investigation of the source or sources of sustained annular pressure in the B and C annuli exhibited by several wells was undertaken. All surface indications were that gas at relatively low pressure was the charging medium, and for each well a bespoke program was crafted by the Archer specialists to fully investigate all potential failure modes. Despite the low rates of gas migration, VIVID was able to successfully detect and map the flow in each case, giving invaluable insight to the dynamics of the integrity breach.

P&A campaign planning

The proven ability to detect migrating gas, even at low rates and differential pressures, brings a benefit to the planning of permanent abandonment campaigns. The small diameter of the tool (111⁄16 in.) coupled with its extremely low detection threshold allows investigation of the sources of sustained annular pressure through tubing before mobilizing a rig to location. Full investigation of any well exhibiting anomalous surface pressure behavior might be undertaken on a fieldwide basis before commenting operations, allowing detailed planning to be conducted to maximize the efficiency and minimize the cost of the campaign.

At a time when the industry continues to focus on efficiencies, costs and safety, robust and comprehensive cement evaluations are becoming more important than ever. Over the life of a well, it is no longer acceptable to consider only the physical presence of cement as an effective barrier. Archer and VIVID are addressing just that—investigating the performance of cement and detecting even small fluid movements, characterizing migration paths with unparalleled sensitivity and allowing confidence in future barrier integrity.

Have a story idea for Tech Watch? This feature highlights leading-edge technology that has the potential to eventually address real-life upstream challenges. Submit your story ideas to Group Managing Editor Jo Ann Davy at jdavy@hartenergy.com.

Recommended Reading

Buffett: ‘No Interest’ in Occidental Takeover, Praises 'Hallelujah!' Shale

2024-02-27 - Berkshire Hathaway’s Warren Buffett added that the U.S. electric power situation is “ominous.”

Why Endeavor Energy's Founder Sold His Company After Years of Rebuffing Offers

2024-02-13 - Autry Stephens', the 85-year-old wildcatter, decision to sell came after he was diagnosed with cancer, according to three people who discussed his health with him.

CEO: Coterra ‘Deeply Curious’ on M&A Amid E&P Consolidation Wave

2024-02-26 - Coterra Energy has yet to get in on the large-scale M&A wave sweeping across the Lower 48—but CEO Tom Jorden said Coterra is keeping an eye on acquisition opportunities.

CEO: Magnolia Hunting Giddings Bolt-ons that ‘Pack a Punch’ in ‘24

2024-02-16 - Magnolia Oil & Gas plans to boost production volumes in the single digits this year, with the majority of the growth coming from the Giddings Field.

Occidental Increases Annual Dividend by 22%

2024-02-11 - Occidental Petroleum Corp.’s newly declared dividend is at an annual rate of $0.88 per share, compared to the previous annual rate of $0.72 per share.