(Source: Shutterstock.com; image of Baker Hughes Lucida advanced rotary steerable service courtesy of Baker Hughes Co.)

Learn more about Hart Energy Conferences

Get our latest conference schedules, updates and insights straight to your inbox.

[Editor's note: This article and video originally appeared in the October issue of E&P Plus. Subscribe to the digital publication here.]

Companies collaborate to create 2D, 3D real-time well visualization

Weatherford International Plc announced a collaboration with INT, an upstream data visualization provider, to offer real-time well visualization in both 2D and 3D. Weatherford will embed INT’s IVAAP framework into the Weatherford Centro digital well delivery software, advancing its data visualization capabilities. The digital well delivery software offers workflows that integrate every element of an operator’s well data, allowing team members from any global location to access, share and store all vital project information at any time.

Technology can help speed soil recovery after oil spills

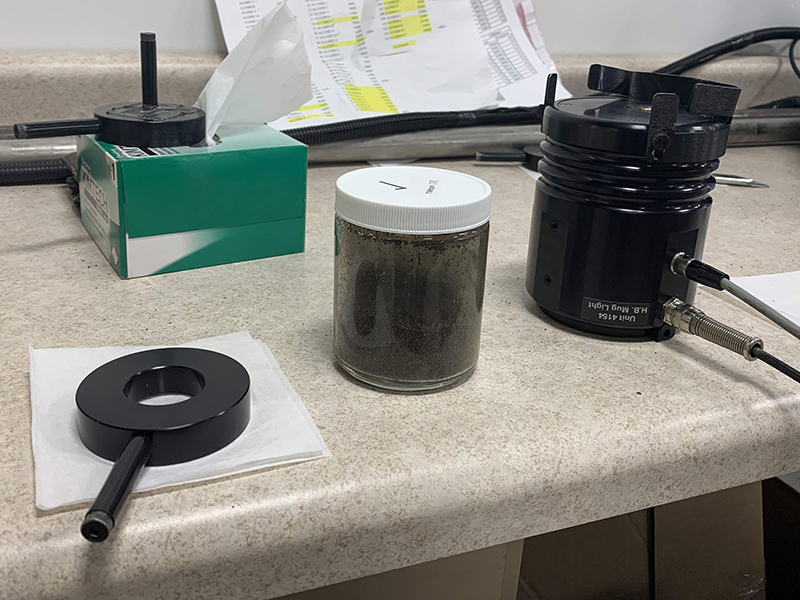

After an oil spill or leak, it is important to act fast. If the oil has gotten into soil, scientists need to rapidly assess how much oil there is and how far it has spread. It is a costly and time-consuming process. A team at University of Nebraska-Lincoln found a new method using technology called Vis-NIR spectroscopy that is faster and cheaper.

The traditional methods for analyzing these soils are done in the laboratory and involve multiple steps. It requires collecting samples from the spill site and then taking them off site for analysis. The Vis-NIR spectroscopy technology works by sending wavelengths of energy at a sample and measuring what is absorbed or reflected. Different chemical substances do this very specifically based on their makeup, so it is able to tell scientists a lot about a sample. The data they receive from the technology have to be compared to a model. They found they could construct accurate model samples mostly in the laboratory, with only a few samples from the site needed. Adding just a few field samples, rather than relying solely on them, is a process called spiking. This reduction of time and labor necessary at the oil spill site makes this new method rapid and cheap.

During spiking, the data from the field samples are added into the original model. This helps customize the model to make it more accurate for the specific location.

The cost of the VisNIR-based method is just a few dollars per sample, compared to the traditional cost of $50 per sample. Additionally, rather than taking days or weeks to get results, the results are almost instant. The tool can also be taken right into the field to speed up the overall project.

Using quantum gravity sensors down boreholes

Experts in quantum cold-atom sensors are delving deep underground in a new project aimed at harnessing quantum gravity-sensing technology in harsh underground borehole environments. The Gravity Delve project, funded by Innovate UK, brings together academics from the UK Quantum Technology Hub Sensors and Timing, which is led by the University of Birmingham and Nemein Ltd., with the aim of investigating the benefits and challenges associated with using quantum gravity sensors down boreholes. Quantum gravity sensors based on atom interferometry are already being developed for use in the oil and gas sector. Quantum cold-atom sensors designed to operate on the surface will be able to detect and monitor objects beneath the ground better than any current technology. Nemein is developing borehole deployed equipment primarily focused on energy harvesting and environmental sensing. The new technology will enable the quantum sensor developed by the University of Birmingham to venture out of the laboratory and into the extremely harsh downhole environment.

Borehole applications to be investigated in the project will include carbon capture and storage (CCS) as well as hydrocarbon and geothermal reservoirs. Existing techniques for reservoir optimization include conventional microgravity, electrical and nuclear logging. These techniques, however, are limited by sensitivity, resolution and cost. Gravity Delve is investigating how a commercially relevant quantum device could replace or enhance current technology to optimize CCS reservoirs, minimize the environmental impact from hydrocarbon extraction and enhance the transition from fossil fuels to renewable energy such as geothermal. The project will develop a design for a borehole quantum cold-atom gravity sensor as well as the associated harsh environmental packaging and ancillary equipment. According to the project leaders, this will lead to the first cost-effective and efficient method deep borehole quantum sensor deployment.

Alliance provides integrated, open architecture software to maximize asset potential

Halliburton and Honeywell announced a collaboration to maximize asset potential, reduce execution risk and lower the total cost of ownership for oil and gas operators. The collaboration will leverage Halliburton Landmark’s DecisionSpace 365 E&P cloud applications and the Honeywell Forge industrial analytics software to deliver insights about oil and gas assets. Together, the companies bring deep domain expertise in subsurface and surface operations with the latest digital innovations to help operators address operational efficiency, asset productivity and risk across their business. Operators will be able to maximize asset value by creating a digital twin on an integrated and open architecture that connects and models the supply chain from reservoir to point of sale. They will also be able to increase production, minimize opex/capex and reduce operational risks by streamlining processes from downhole to surface controls, including digital solutions for improved subsurface insight. Additionally, the collaboration can offer optimization of total asset and enterprise performance using real-time monitoring and remote operations.

App provides market insights and transparency

Online valuation and data provider, VesselsValue, has released its first official app. The free app is designed to ensure users can quickly obtain market insights and reinforces the company’s proposition of making markets transparent and accessible. The app allows users to view current market, demolition and newbuild values for every vessel including company fleet values within the database. It also allows users to search the extensive VesselsValue database for any vessel or company fleet in the world. The app provides an interactive graph that features historical values and vessel transactions. Users can also view the specific details of each vessel (e.g., builder, flag, size, features and more). VesselsValue plans to expand the app’s functionality and add additional features over the coming months. The app covers all ship types on the VesselsValue platform, including cargo ships, offshore vessels and passenger vessels, among others. The app is available on iOS and Android platforms.

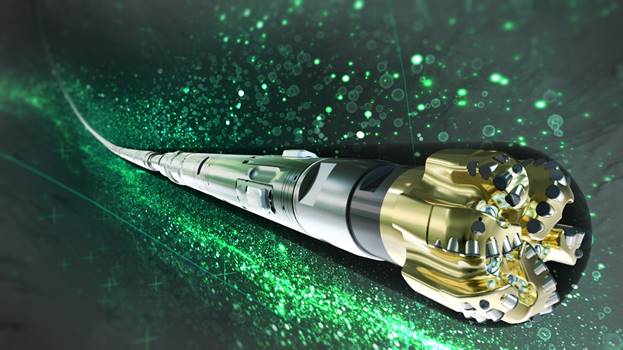

New rotary steerable service for high-performance drilling

Baker Hughes has released its new Lucida advanced rotary steerable service, which integrates hardware, software, automation and remote connectivity to help oil and gas operators drill faster and deliver more precise, higher-quality wells. The service is designed to maximize directional drilling performance and well productivity by incorporating advanced electronics and near-bit sensors that enable drillers to more precisely guide bottomhole assemblies (BHAs). The Lucida service’s integrated BHA includes a customized drill bit and high-strength connections to maximize penetration rates. The BHA also includes near-bit sensors to gather more downhole data and multi-chip module electronics, which have been tested extensively at temperature cycles approaching 400 F to provide a step change in reliability in more demanding drilling environments. The service’s 16-sector gamma-ray sensors are situated close to the bit and provide real-time formation data that enable quick decisions to navigate the reservoir more precisely. Lucida’s automated wellpath trajectory control system integrates both azimuthal and inclination hold modes with continuous proportional steering to automatically correct wellbore trajectory for formation trends.

New DC/DC converter designed for extreme environments

WAGO has released its new 12 to 24 VDC DIN Rail mountable converter for extreme conditions. This XTR DC/DC converter has conformal coating, which provides increased effectiveness against harsh environments. It can be used in a wide range of temperatures from 40 C to more than 70 C and is suitable for extreme applications. Other features include reverse polarity and short circuit protection, which prevents problems with mis-wiring, as well as 95% efficiency at full load, which reduces energy loss and provides full ampacity without derating. These converters are useful in environments that require extreme testing procedures and can provide up to 3 Amps.

Editor’s note: The copy herein is compiled from press releases and product announcements from service companies and does not reflect the opinions of Hart Energy. Submit your company’s updates related to new technology products and services to Faiza Rizvi at frizvi@hartenergy.com.

Recommended Reading

Kimmeridge Fast Forwards on SilverBow with Takeover Bid

2024-03-13 - Investment firm Kimmeridge Energy Management, which first asked for additional SilverBow Resources board seats, has followed up with a buyout offer. A deal would make a nearly 1 Bcfe/d Eagle Ford pureplay.

Laredo Oil Subsidiary, Erehwon Enter Into Drilling Agreement with Texakoma

2024-03-14 - The agreement with Lustre Oil and Erehwon Oil & Gas would allow Texakoma to participate in the development of 7,375 net acres of mineral rights in Valley County, Montana.

Hess Corp. Boosts Bakken Output, Drilling Ahead of Chevron Merger

2024-01-31 - Hess Corp. increased its drilling activity and output from the Bakken play of North Dakota during the fourth quarter, the E&P reported in its latest earnings.

The OGInterview: Petrie Partners a Big Deal Among Investment Banks

2024-02-01 - In this OGInterview, Hart Energy's Chris Mathews sat down with Petrie Partners—perhaps not the biggest or flashiest investment bank around, but after over two decades, the firm has been around the block more than most.

Petrie Partners: A Small Wonder

2024-02-01 - Petrie Partners may not be the biggest or flashiest investment bank on the block, but after over two decades, its executives have been around the block more than most.