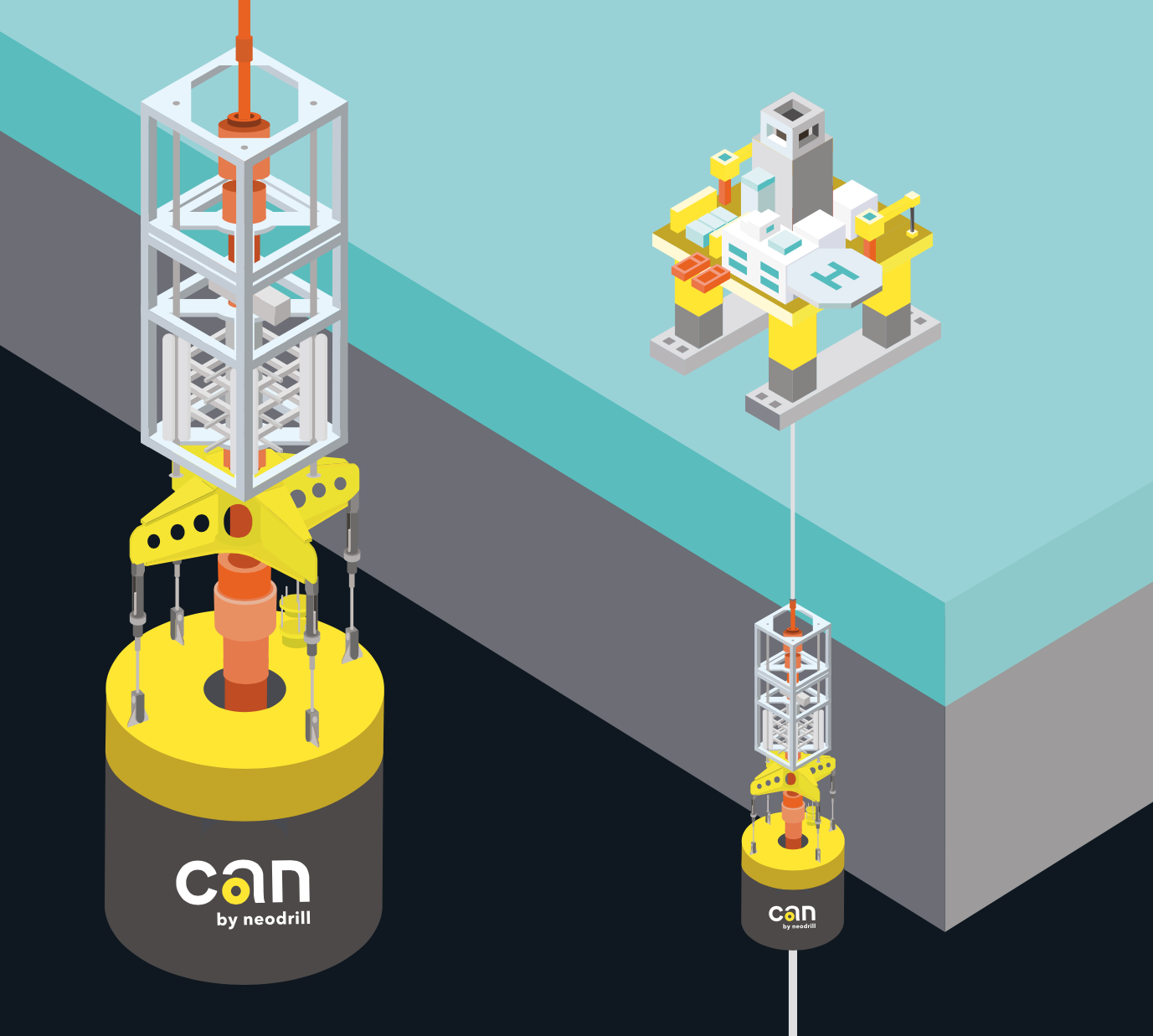

Neodrill released its new Wellhead Saver System, pictured, to address the challenge of drift-off within the oil and gas industry. (Source: Shutterstock.com; image of wellhead system courtesy of Neodrill)

[Editor's note: A version of this story appears in the July 2020 edition of E&P. Subscribe to the magazine here.]

Testing new technologies to reduce methane emissions

Exxon Mobil Corp. is conducting field trials of eight methane detection technologies, including satellite monitoring, to cut down on greenhouse-gas emissions. The company said the pilot project is being carried out at nearly 1,000 sites in Texas and New Mexico using drones, planes and helicopters, and ground-based mobile and fixed-position sensors. All technologies and deployment methods will be used to detect leaks and identify solutions that can be shared with other oil and gas operators. Exxon Mobil has called for tighter regulation of methane and offered up its own in-house rules as a model for companies and lawmakers worldwide. The company has laid out the guidelines it follows at a time when the industry faces growing pressure from investors to reduce its environmental footprint.

Companies partner to deliver enhanced swellable sealing for operators

Tendeka has partnered with Wellvene, a design engineering and manufacturing company, to release a new version of its SwellStack swellable sealing. The enhanced Tendeka/Wellvene SwellStack provides cost-effective sealing that is compatible with all Wellvene and original equipment manufacturer insert safety valves. The upgraded technology ensures production can be reinstated to wells that are closed in due to the failed sealing of an insert safety valve, thereby eliminating higher costs and long lead straddles or potential workovers. Downhole safety valve seal bores can become corroded or damaged due to intervention activities. Standard chevron stacks commonly provided for insert safety valves may be unable to effectively seal within such damaged bores. This results in a leak path for hydrocarbons to migrate up the control line. In such cases, the only solution is to perform a straddle installation or workover the upper completion and replace the damaged valve. Both options are costly and time consuming. Originally launched by Tendeka in 2013, the SwellStack has been utilized in more than 180 installations globally. Comprising swellable O-ring technology and a chevron seal design, the swellable O-ring expansion within the damaged bore activates the chevron seals to both effectively and reliably provide integrity for up to 10,000 psi in liquid and gas.

New technology reduces idle rig time

Neodrill has released its new Wellhead Saver System (WSS) to address the industry challenge of drift-off. According to estimates, the new system will deliver savings of six to 12 rig days on a typical well. When deepwater rigs are used under shallow-water conditions, the forces and bending moments from the BOP and riser are placed on the wellhead. The new WSS adapts Neodrills’ Conductor Anchor Node (CAN) well foundation to redirect the bending forces away from the wellhead directly into the well foundation. By protecting the wellhead, conductor and casing from overbending and overstressing, it is possible to increase the drift-off distance before disconnect occurs. This allows the rig to stay on location and remain connected to the well in severe weather conditions, saving idle rig time costs. Compared to the traditional approach of tethering the BOP and wellhead system down, the WSS is connected to both the wellhead and the CAN, which allows it to act as a wellhead saver sub. This process enables drilling operations to take place without loading the original wellhead. It also facilitates the installation of the production tree on a virgin wellhead. Compared to the BOP tethering system, it avoids long steel and fiber wires that may require re-tensioning during operations. The use of the CAN technology, as well as the reduced weight of the system in comparison to the BOP tethering system, also reduces the CO2 footprint.

New compressors for offshore vessels to reduce emissions

TMC Compressors of the Seas has released a range of marine compressors using air lubrication systems to help ships and offshore vessels further reduce fuel consumption and emissions. Using air lubrication systems is a method used to reduce the resistance between the ship’s hull and seawater by using air bubbles. The air bubble distribution across the hull surface reduces the resistance working on the ship’s hull, creating energy-saving effects. TMC’s marine compressed air systems for air lubrication systems can be utilized to generate the required stream of air bubbles that passes continuously beneath the ship’s surface, thereby reducing frictional resistance between the hull and the seawater. TMC will offer a wide range of large compressors for air lubrication system applications, ranging from 50 kW to 400 kW capacity. TMC also has developed an associated electronic air lubrication control system that is integrated into a specially designed control room cabinet. For air lubrication systems, air bubble outlets are created at different locations along the bottom of the hull, ideally symmetrically on both sides of the ship’s centerline. In combination with TMC’s air lubrication system compressors, the system can continuously ensure that a uniform layer of air bubbles is maintained beneath the ship and produces the desired energy-saving effect.

Intelligent upstream technology to streamline processes and costs

Accenture and SAP have co-developed a solution for upstream oil and gas companies based on SAP S/4HANA Cloud. Using intelligent technologies, such as artificial intelligence, the SAP S/4HANA Cloud technology further increases visibility into operations and cash flow. Available globally, SAP S/4HANA Cloud is a scalable solution that can help oil and gas companies reduce the total cost of ownership and operational costs as well as create new revenue opportunities. Tools for preconfigured, integrated and user-friendly business processes are included so that companies can shrink implementation time while working to reduce risk of business disruption. The technology delivers new industry standards, which help simplify operations and free up resources to drive more business value. To define market-standard, end-to-end processes that are preconfigured within the technology, Accenture and SAP are working with a consortium of E&P companies, including BP, Chevron, ConocoPhillips, Equinor and Shell.

New underwater drones for efficient offshore operations

Nido Robotics has released the Sibiu Pro and Sibiu Nano underwater drones, which are designed to bring precision, flexibility and convenience to underwater operations. The Sibiu Pro weighs 16 kg, is capable of operating at depths of 300 m and can travel at a maximum speed of 3 knots. It features an integrated 1080p camera, calibrated specifically for underwater usage and accompanied with four regulation-controlled 1,500 lumens lights, which guarantees crisp, high-resolution live images. The modular system construction is designed to enable a variety of different payloads to be carried, opening up a broad range of underwater research, inspection and maintenance possibilities. The Sibiu Pro is complemented with a smaller version, the 5-kg Sibiu Nano, designed for deployment in challengingly tight undersea environments inaccessible by larger ROVs. With a depth rating of 100 m and a compact, practical transport suitcase, the Sibiu Nano echoes the deft lateral maneuverability, user-friendliness and high-spec features of its larger counterpart. Like the Sibiu Pro, it is equipped with an integrated 1080p camera and offers full mission autonomy as its powerful interchangeable batteries will hold their charge for up to 2 hours at a time.

Editor’s note: The copy herein is compiled from press releases and product announcements from service companies and does not reflect the opinions of Hart Energy. Submit your company’s updates related to new technology products and services to Faiza Rizvi at frizvi@hartenergy.com.

Recommended Reading

To Dawson: EOG, SM Energy, More Aim to Push Midland Heat Map North

2024-02-22 - SM Energy joined Birch Operations, EOG Resources and Callon Petroleum in applying the newest D&C intel to areas north of Midland and Martin counties.

Chevron Hunts Upside for Oil Recovery, D&C Savings with Permian Pilots

2024-02-06 - New techniques and technologies being piloted by Chevron in the Permian Basin are improving drilling and completed cycle times. Executives at the California-based major hope to eventually improve overall resource recovery from its shale portfolio.

Stena Evolution Upgrade Planned for Sparta Ops

2024-03-27 - The seventh-gen drillship will be upgraded with a 20,000-psi equipment package starting in 2026.

TotalEnergies Starts Production at Akpo West Offshore Nigeria

2024-02-07 - Subsea tieback expected to add 14,000 bbl/d of condensate by mid-year, and up to 4 MMcm/d of gas by 2028.

Shell Brings Deepwater Rydberg Subsea Tieback Onstream

2024-02-23 - The two-well Gulf of Mexico development will send 16,000 boe/d at peak rates to the Appomattox production semisubmersible.