(Source: TGT Diagnostics)

Mechanical “multifinger” calipers have been used routinely by integrity managers for decades as the primary diagnostic method to evaluate production tubulars, partly because they offer a broad range of benefits, but partly because there was no viable alternative.There is now another option.

The miles of metal tubulars that form the backbone of the well system are fundamental to its integrity. Chief among these are the production tubing and production casing, often referred to as “primary tubulars” or “primary barriers” because of their special role in keeping wells safe, clean and productive. Primary tubulars are the central conduits that transport fluids between reservoirs downhole and the wellhead. Collectively, primary tubulars form the wellbore and, from an integrity perspective, their main task is one of containment—keeping pressurized fluids safely inside the well system permanently—protecting and producing 24/7 for the entire life of the well.

But primary tubulars have their work cut out for them; they need to unfailingly withstand the rigors of downhole conditions. Well systems are dynamic and can be hostile environments for man-made materials, even steel. Extremes and variations of pressure and temperature can cause mechanical stresses, well fluids can potentially corrode and erode the steel tubes, and mechanical interventions can cause additional wear over time. Regular inspection is therefore important to ensure continued safe, clean and productive operations.

Tube diagnostics

Tube inspection tends to focus on three main attributes: tube wall thickness, tube wall defects and tube geometry. And although tube geometry or profiling is important, wall thickness and defect sensing are typically the two main objectives from an integrity perspective.

With these applications in mind, the industry has developed a number of diagnostic technologies and methods aimed at tracking the condition of primary tubulars. Each has its strengths and drawbacks in terms of accuracy, resolution, coverage, efficiency and cost, when measured against their ability to assess wall thickness, defects and geometry. In a recent industry survey of 100 well integrity management professionals conducted by TGT, mechanical “multifinger” calipers were identified as the most prolific diagnostic method used to evaluate production tubing. For production casing, electromagnetic and ultrasound techniques were the most popular, but calipers were still prominent.

Mechanical calipers offer a broad mix of attributes that make them suitable for tube diagnostics. They are widely available to suit all sizes of production tubing and casing, they are relatively inexpensive and easy to deploy, and can provide comprehensive assessment in all three areas of wall thickness, defect sensing and tube geometry. However, calipers have several application-specific drawbacks, mainly in terms of accuracy in determining actual wall thickness in some scenarios, and sensing small defects.

According to the industry survey of integrity managers, the most important attributes experts consider when selecting diagnostic methods to evaluate production tubing are: the accuracy and sectorial coverage of wall thickness measurements, and the completeness and resolution of defect sensing. Geometry assessment is a lesser priority. Furthermore, the experts required a wall thickness accuracy of at least ±3% and a defect resolution of approximately 3 mm.

To track tube wall thickness, calipers measure internal diameter (ID) and estimate thickness by assuming a nominal outside diameter (OD). Variations in the actual OD or external corrosion, both invisible to calipers, can invalidate the thickness value. Also, scale or wax deposits on the inner surface can mask internal defects and lead to further false thickness computations. And while the accuracy of caliper ID measurements is approximately ±5% (±0.5 mm), the total system error for wall thickness can reduce to ±10% (±1 mm), or worse if there is scale or external corrosion. This accuracy is far below the ±3% level currently required by integrity managers.

For defect sensing, calipers offer highly precise radial measurements via 24, 40 or 60 fingers spaced azimuthally around the inner tube surface. Thin, 1.6 mm fingertips can sense the smallest defects provided the defect lies in the path of the finger passing over it. Practically, there are gaps between fingers that vary according to tube size and finger density. For example, the gap between 24 fingers in 3-1/2 inch, tubing is about 7 mm. This means that the fingers only sense about 10%-30% of the inner wall surface and it is possible for small defects or holes to pass undetected between fingers.

A new alternative

Despite the drawbacks, mechanical calipers have been used routinely by integrity managers for decades as the primary diagnostic method to evaluate production tubing, partly because they offer a broad range of benefits, but partly because there was no viable alternative.

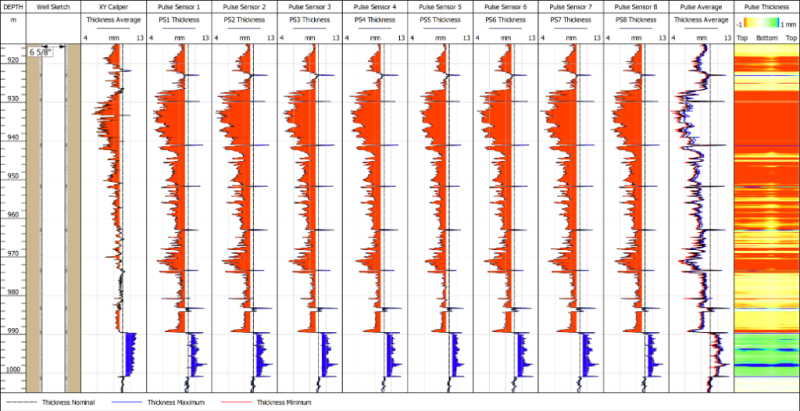

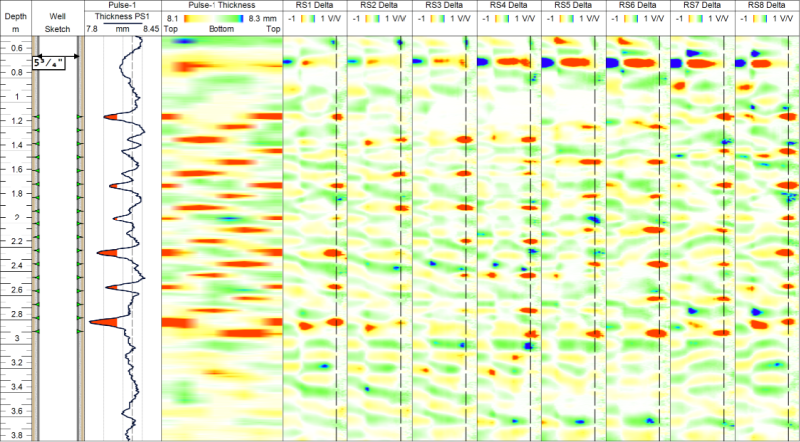

In an effort to provide an alternative, TGT has developed a new diagnostic platform that can be used independently, or together with calipers or other techniques to provide a more accurate and comprehensive evaluation of tube integrity. Pulse1 is the industry’s first slim tube integrity technology capable of delivering “true wall thickness” measurements of production tubing in eight sectors, with complete all-around sensing of tube wall condition.

Unlike calipers that measure ID to estimate thickness, Pulse1 uses electromagnetic energy to measure actual metal wall thickness directly. This can translate into greater accuracy, especially if the tube wall is coated with scale or has external corrosion. Pulse1 delivers eight sectorial wall thickness measurements up to an accuracy of ±2% in all common tubing sizes, and up to ±3.5% in production casings. This meets or exceeds new industry requirements and represents about a five-fold improvement on caliper accuracy.

In terms of defect sensing, Pulse1 can sense localized metal loss defects equivalent to 7-10 mm diameter holes in the most common production tubing sizes. Calipers offer greater resolution, and Pulse1 provides greater coverage, so combining both delivers a more comprehensive assessment then previously possible.

Efficiency, versatility and chrome

Corrosion-resistant chrome alloy completions provide protection from corrosive and toxic fluids, and the inner wall surfaces are often coated with an additional thin protective film. Many operators prefer not to use calipers to inspect such completions because the millimeter-thin tips of caliper fingers might scratch the inner surface, exposing the alloy and leaving it vulnerable to attack. It’s a dilemma because regular inspection is essential, and previous electromagnetic methods only provided an average non-sectorial thickness measurement. Pulse1 provides eight thickness measurements and is deployed with soft-touch roller centralizers with less point-pressure on the tube wall, minimizing the risk of scoring. This makes it a safer alternative for inspecting chrome completions. And because Pulse1 utilizes ultra-fast sensing technology and time-domain techniques, it is as effective in chrome alloys as in conventional steel tubulars.

In terms of efficiency, diagnostic interventions cost time and money. The Pulse1 tool OD is 48 mm slim and delivers accurate sectorial wall thickness in tube sizes from 2-7/8 inch to 9-5/8 inch. This means operators can survey production tubing and the casing below the tubing shoe in a single deployment, saving rig time and intervention costs. Combining Pulse1 with Pulse4 enables multi-barrier assessment, and both can be deployed rigless on slickline improving efficiency.

Enhancing integrity management

The oil and gas industry is continually raising integrity standards and moving closer to a “no compromise” approach, and this development is helping the industry to achieve that goal. For applications where accurately tracking wall thickness is the main priority, Pulse1 can be considered as a reliable and practical alternative to mechanical calipers. And if the well is prone to scale, wax or external corrosion, Pulse1 can deliver significantly improved accuracy. If the diagnostic objective is a more comprehensive no compromise evaluation, then combining Pulse1 with caliper will offer the best results.

Recommended Reading

NextEra Energy Dials Up Solar as Power Demand Grows

2024-04-23 - NextEra’s renewable energy arm added about 2,765 megawatts to its backlog in first-quarter 2024, marking its second-best quarter for renewables — and the best for solar and storage origination.

Halliburton’s Low-key M&A Strategy Remains Unchanged

2024-04-23 - Halliburton CEO Jeff Miller says expected organic growth generates more shareholder value than following consolidation trends, such as chief rival SLB’s plans to buy ChampionX.

Enverus: Q1 Upstream Deals Hit $51B, But Consolidation is Slowing

2024-04-23 - Oil and gas dealmaking continued at a high clip in the first quarter, especially in the Permian Basin. But a thinning list of potential takeout targets, and an invigorated Federal Trade Commission, are chilling the red-hot M&A market.

Baker Hughes Awarded Saudi Pipeline Technology Contract

2024-04-23 - Baker Hughes will supply centrifugal compressors for Saudi Arabia’s new pipeline system, which aims to increase gas distribution across the kingdom and reduce carbon emissions

Ithaca Energy to Buy Eni's UK Assets in $938MM North Sea Deal

2024-04-23 - Eni, one of Italy's biggest energy companies, will transfer its U.K. business in exchange for 38.5% of Ithaca's share capital, while the existing Ithaca Energy shareholders will own the remaining 61.5% of the combined group.