Presented by:

Editor's note: This article originally appeared in the May issue of E&P Plus.

Subscribe to the new E&P digital newsletter here.

Maintaining high-accuracy flow rate metering for the life of the well is critical for maximizing reservoir productivity and planning an intervention strategy. The ability to accurately measure oil, gas, and water flow rates, preferably in real time, enables operators to make better-informed production decisions with key information about well dynamics.

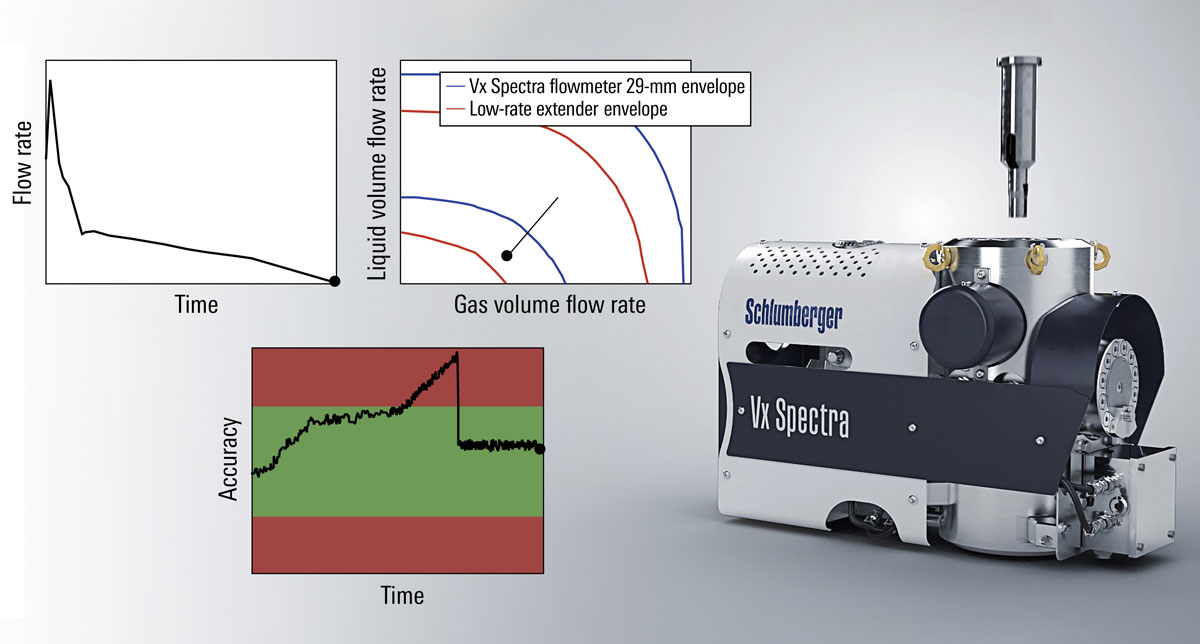

To accurately capture production flow, multiphase flowmeters are sized for specific flow rate ranges before installation. However, as wells mature and production inevitably declines, the differential pressure (dP) across the venturi section of a multiphase flowmeter may become so low that flow rate accuracy is difficult to maintain. The dP measurement provides raw information about the momentum of the flow and is closely related to the mass flow rate of the fluid going through the meter. For wells in production decline, dP readings may be outside the standard meter operating envelope, directly affecting the flow rate measurement accuracy.

Whereas conventional wells typically experience a gradual decline over decades of production, unconventional wells generally see a much sharper drop within the first few years, accompanied with water cut and fluid property changes. Particularly for North America land applications, operators need a quick, cost-efficient solution to enable continuous high-accuracy multiphase flow rate data for wells in production decline.

Conventional approaches to maintaining high metrological performance

Venturi sections with a 29-mm size address midrange multiphase metering at the majority of oil production fields. Typically, meters are replaced for a smaller size to increase the turndown ratio and thus operational metering envelope in depleting wells. However, this approach strains capex and increases nonproductive time (NPT).

Furthermore, the practice of installing a separator to act as a metering device has proven to be both capex- and opex-intensive. Operators have found it challenging to manage the optimal turndown ratio, a process that requires constant attention and places timing demands on personnel to service equipment. Separators also require continuous control over various moving parts to maintain the operational integrity, requiring more maintenance. Moreover, with unavoidable solids buildup during production, it becomes necessary to regularly empty the separators as they slowly fill with solids, especially as production rates decline. These are challenges that advanced surface meters such as the Vx Spectra surface multiphase flowmeter have resolved by its lack of moving parts and incorporating drain passages to flush the pressure membranes and the passage through the venturi when clogged. This enhances the surface multiphase flowmeter performance and reduces intervention time.

Expanding the operational envelope

By combining full-gamma spectroscopy and high-frequency flow rate and phase fraction measurement at a single point in the venturi throat, the surface multiphase flowmeter ensures accurate, repeatable and real-time flow rate measurement without phase separation. For wells in production decline, a solution that expands this same metering accuracy and real-time insights can help operators make improved decisions.

Instead of replacing the field infrastructure, retrofitting an existing 29-mm surface multiphase flowmeter is a new solution for achieving more cost-efficient high-accuracy metering in depleting wells. By installing a lightweight, compact insert across the venturi section of the flowmeter, operators can reduce both the capex and NPT associated with conventional methods and ensure more continuous flow rate measurement and data insights for the life of the well. Typically, installation takes less than half a day, as opposed to two days with replacing for a new, smaller meter.

The multiphase surface flowmeter provides robust measurement over a large range of gas volume fractions (GVFs), with a turndown ratio over 10 for a fixed GVF. Because the insert reduces the cross-sectional area at the venturi throat, the turndown ratio increases by at least two times, thus expanding the measured dP to accommodate for low flow rates. This increased operating envelope results in high-accuracy flow rate measurement for wells in production decline, eliminating the need to replace the existing meter. In addition to the increased turndown ratio, flow rate accuracy is maintained due to an updated flow model that describes the multiphase flow through the unique cross-sectional shape formed by the low-rate extender insert at the venturi throat. Extensive validation in a multiphase flow loop under a wide variety of flow conditions has demonstrated the effectiveness and accuracy of the insert solution. The low-rate extender insert also does not interfere with the gamma ray beam, thus maintaining the same photon count rates and consequently phase fraction and water cut accuracies.

Case study: Maintaining flow rate accuracy in the Permian

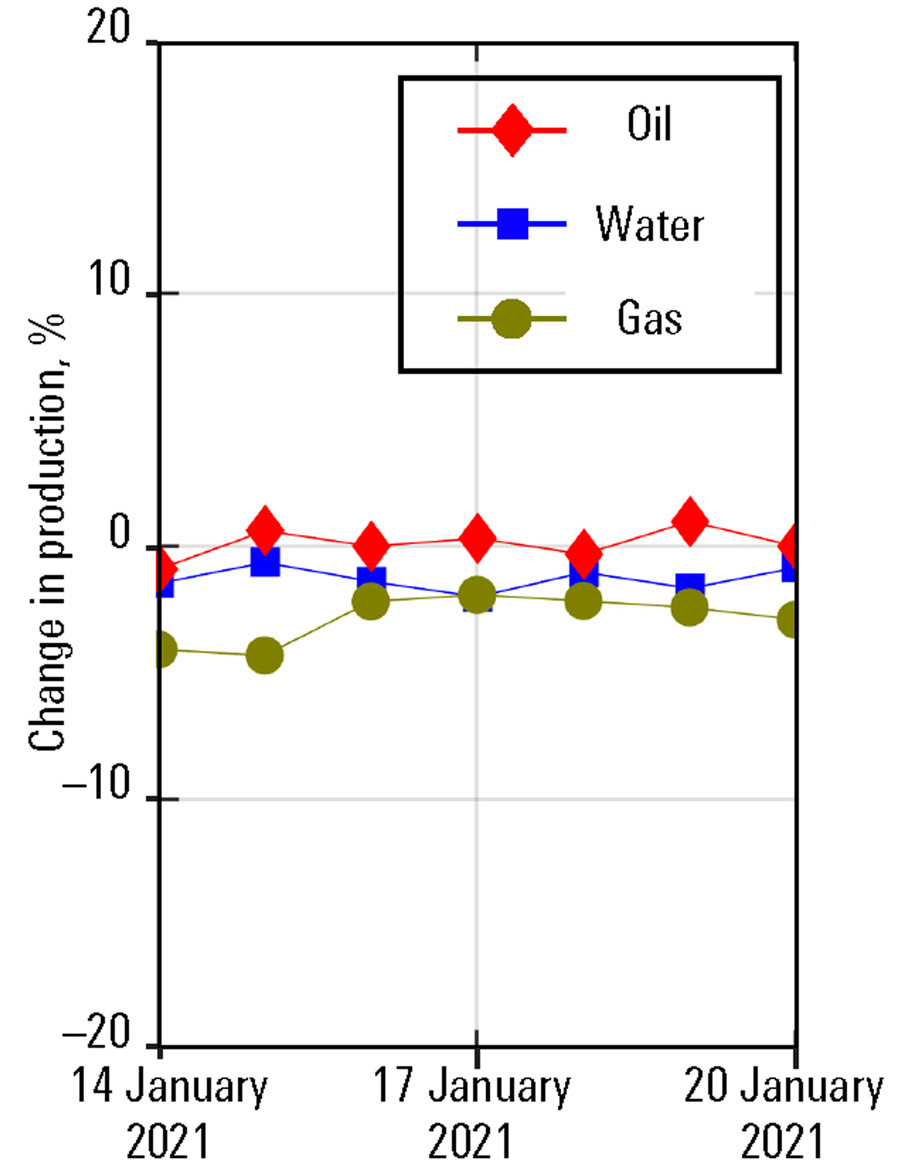

Field tests in U.S. unconventional oil and gas wells demonstrate the usability and robustness of the low-rate extender insert to deliver reliable, high-quality multiphase data for wells in production decline. An unconventional shale well in Texas was brought online in 2019, and production started to gradually decline. Within six months, liquid production decreased by half, and gas production decreased by 25%. Due to production decline, the well’s low flow rate was outside the installed flowmeter’s operational envelope. The field’s operator was faced with needing to replace the existing 29-mm flowmeter for a smaller size to maintain dP values above the low limit and operate in the working envelope for metering accuracy.

To avoid infrastructure changes, lost production time and additional costs, the operator chose to retrofit the existing surface multiphase flowmeter with a low-rate extender. The insert was installed for a trial test in June 2020. After installation in the venturi cross-sectional area, the measured dP increased by more than four times—expanding the operational capacity of the existing 29-mm flowmeter and resulting in more accurate flow rate measurement.

The flow rate measurements were compared with production separator data in real time, and the flowmeter metrological specifications and operating envelope were proven to be maintained. The operator saved capex and NPT by running the same flowmeter for an extended period, accommodating the flow rate changes from an initial high production to steep production decline and demonstrating the low-rate extender’s capability to maintain high-accuracy metering for the life of the well.

Efficiently optimizing production for the life of the well

The low-rate extender insert provides a cost-efficient solution to expand the operational metering envelope by optimizing existing field infrastructure instead of replacing equipment. This method significantly reduces capex and NPT while maintaining the flowmeter’s high metrological performance for wells in production decline. Operators can also further reduce production downtime by including the low-rate extender insert during the initial meter installation to proactively plan for production and flow rate changes as wells mature.

Obtaining continuous, accurate multiphase flow dynamics enables delivering reliable production data for accurate production profiling. The low-rate extender insert maintains this reliability for the life of the well, providing operators with the measurements they need to efficiently manage and optimize their production.

Recommended Reading

Brett: Oil M&A Outlook is Strong, Even With Bifurcation in Valuations

2024-04-18 - Valuations across major basins are experiencing a very divergent bifurcation as value rushes back toward high-quality undeveloped properties.

Marketed: BKV Chelsea 214 Well Package in Marcellus Shale

2024-04-18 - BKV Chelsea has retained EnergyNet for the sale of a 214 non-operated well package in Bradford, Lycoming, Sullivan, Susquehanna, Tioga and Wyoming counties, Pennsylvania.

Defeating the ‘Four Horseman’ of Flow Assurance

2024-04-18 - Service companies combine processes and techniques to mitigate the impact of paraffin, asphaltenes, hydrates and scale on production — and keep the cash flowing.

Santos’ Pikka Phase 1 in Alaska to Deliver First Oil by 2026

2024-04-18 - Australia's Santos expects first oil to flow from the 80,000 bbl/d Pikka Phase 1 project in Alaska by 2026, diversifying Santos' portfolio and reducing geographic concentration risk.

Ozark Gas Transmission’s Pipeline Supply Access Project in Service

2024-04-18 - Black Bear Transmission’s subsidiary Ozark Gas Transmission placed its supply access project in service on April 8, providing increased gas supply reliability for Ozark shippers.