ChampionX devised a highly concentrated scavenger that significantly reduced the volume required. (Source: ChampionX)

Presented by:

Editor's note: This article originally appeared in the May issue of E&P Plus.

Subscribe to the new E&P digital newsletter here.

H2S is a highly poisonous, flammable and corrosive chemical compound often encountered during oil and gas exploration and production activity. Due to its hazardous nature, H2S levels must be closely monitored during offshore operations to assure personnel safety and productivity.

In addition to health and safety concerns, the extremely corrosive nature of the colorless gas can result in significant damage to wells, production equipment and pipelines if not managed effectively. If an efficient method to control H2S is not implemented, it can lead to considerably reduced production, with only sweet wells able to be produced.

H2S scavengers are low-hazard, non-corrosive specialized chemical compounds that remove sulfide species. They have become the standard method for offshore operations and are typically injected directly into the sour production. Due to the potentially large volumes required, the scavenger is transported offshore in chemical tote tanks so it can be injected directly or bunkered into facility tanks.

A major global operator recently experienced difficulty managing H2S levels in a gas export line on one of its North Sea assets. The incumbent product was working efficiently, but due to the amount and concentration of H2S being treated, it required six to seven tons of product per day. With limited onboard fixed storage and the remote location of the asset, the amount of scavenger required to meet the demand was limiting full production. The storage of chemicals on deck was also affecting other activities and had the potential to negatively influence an upcoming drilling campaign.

ChampionX was contracted to create and deploy a highly concentrated scavenger which would reduce the amount of chemicals required while delivering a more sustainable and efficient solution.

Evaluating the challenge

H2S scavenger tote tanks can take up significant space on an offshore platform, creating logistical issues and requiring regular movement for continued supply. On this particular asset, up to two 1,000-gal tanks were swapped daily to meet the demand. Economically, the current operation had resulted in expenditure of around $3.5 million per year. Further, with approximately 2,500 tons of product being moved annually, this had a significant impact on the asset’s carbon footprint, which the operator was keen to reduce.

The winter months in the North Sea also created further challenges, as logistics can face significant delays due to harsh weather and high sea states, which meant a safety stock of scavenger was required on deck. To host 21 days of the product offshore, the operator required 30 tanks, which covered a substantial part of the platform’s laydown area. This was a key issue to resolve, as the space was required for essential equipment for planned drilling and well operations.

The incumbent solution was also having a considerable impact on the asset’s production activities. The high volumes of H2S being produced from some wells had resulted in them being shut in, as the platform could not host the amount of scavenger required to treat them all. At its peak, the E&P organization had 4,500 bbl/d of deferred production associated with H2S management.

Devising a sustainable solution

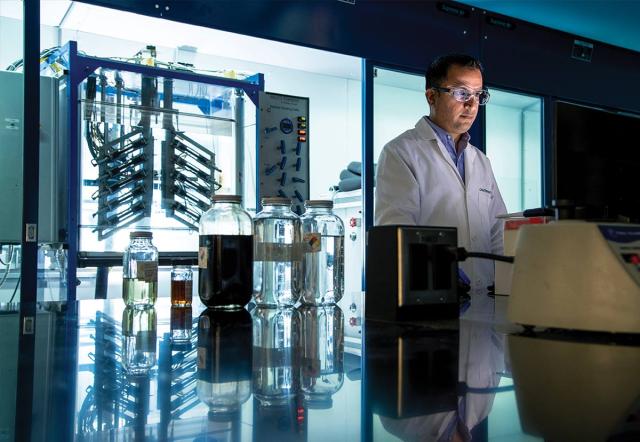

Having discussed the supply challenges with the operator, ChampionX found that increasing the activity of the product could reduce the handling requirements. The company began lab testing to create a bespoke, highly concentrated H2S scavenger, which would reduce the volume required and allow the operator to unlock production from the shut-in wells.

A team of five chemists at the company’s laboratories in Aberdeen, UK, began the initial formulation and testing to devise a more concentrated product, one which would show increased scavenging capacity and, critically, maintain product stability. The process took around one year, with long-term stability and compatibility testing conducted to ensure the product was stable and solids did not form at varying temperatures. Testing was also conducted to confirm the chemical continued to perform optimally.

Materials compatibility was a vital element to be considered in the development. When H2S scavenger is injected into oil and gas processes, it comes into contact with numerous vessels and components, depending on the asset, so the chemical cannot negatively affect the materials. As part of the product commercialization, ChampionX tested the new product on a range of rubbers and metals across varying standards, which are commonly found in the oil field. Once the final chemical formulation was devised, necessary OSPAR and Centre for Environment, Fisheries and Aquaculture Science (CFAS) certifications were secured.

Reducing carbon footprint, increasing efficiency

Upon successful final testing, the company deployed its high-activity HSCV10610A scavenger product to the operator’s platform for definitive field testing.

Once implemented, HSCV10610A delivered annual cost savings of more than $1 million to the client through improved performance over the incumbent product, while continuing to meet the same gas export H2S concentrations.

The reduction in chemical volume of 1.25 million litres decreased the tank changeovers and its associated tasks, resulting in two man-hours per shift saved. This amounted to an annual resource benefit equivalent of $64,000 in terms of lab tech man-hours.

The new scavenger further delivered a 70% reduction in the number of H2S scavenger tote tanks shipped: a yearly saving of $162,000 in tank rental. It also freed up 3.5% (23m2) of all available vessel space per sailing. The reduction in volumes of chemical being transported significantly reduced road and sea transport costs and avoided the production of 231 metric tons of CO2 per year, drastically reducing the operator’s carbon footprint.

The adoption of HSCV10610A allowed the operator to re-start production on the previously shut-in wells, significantly increasing production by up to 4,500 bbl/d.

Implementing this high-activity chemical also allowed the pipe deck to be reclaimed before an essential drilling campaign and was a key step to freeing up platform laydown space for other operations.

The operator continues to utilize ChampionX’s product HSCV10610A, and the highly concentrated solution has become an industry standard in the North Sea.

Supporting the net-zero journey

The removal of H2S is a common issue in the oil and gas industry, and there are various methodologies for its remediation which have their own associated expenditures and challenges. It is essential that solutions ensure the health and safety of those on board, in addition to maintaining crude value and maximizing production.

However, as the UK continues its journey towards net zero, it is no longer enough to create solutions which simply offer efficiencies. Sustainability and reduction of carbon footprint must be prioritized. ChampionX’s bespoke scavenger demonstrates how investment in research and development, coupled with a clear view to deliver an environmental solution can garner significant results for the sector.

Recommended Reading

TGS, SLB to Conduct Engagement Phase 5 in GoM

2024-02-05 - TGS and SLB’s seventh program within the joint venture involves the acquisition of 157 Outer Continental Shelf blocks.

StimStixx, Hunting Titan Partner on Well Perforation, Acidizing

2024-02-07 - The strategic partnership between StimStixx Technologies and Hunting Titan will increase well treatments and reduce costs, the companies said.

Forum Energy Signs MOU to Develop Electric ROV Thrusters

2024-03-13 - The electric thrusters for ROV systems will undergo extensive tests by Forum Energy Technologies and SAFEEN Survey & Subsea Services.

Axis Energy Deploys Fully Electric Well Service Rig

2024-03-13 - Axis Energy Services’ EPIC RIG has the ability to run on grid power for reduced emissions and increased fuel flexibility.

TotalEnergies Rolling Out Copilot for Microsoft 365

2024-02-27 - TotalEnergies’ rollout is part of the company’s digital transformation and is intended to help employees solve problems more efficiently.