Learn more about Hart Energy Conferences

Get our latest conference schedules, updates and insights straight to your inbox.

Presented by:

Editor's note: The full version of this article originally appeared in the February issue of E&P Plus.

Subscribe to the digital publication here.

The Alaska North Slope (ANS) is estimated to contain 20 Bbbl to 30 Bbbl of heavy oil. However, the development pace of that resource has been quite slow due to the high costs of development and the low oil recovery efficiency using conventional waterflood and EOR methods. Even after three decades of development efforts by multiple operators, the total heavy oil cumulative recovery from all ANS fields just reached 255 MMbbl, which was less than 1% of the total heavy oil in place in 2019.

The University of Alaska Fairbanks is leading a project being sponsored by the U.S. Department of Energy National Energy Technology Laboratory (NETL) and Hilcorp Alaska LLC. The project is a four-year field pilot project entitled, “First Ever Field Pilot on Alaska’s North Slope to Validate the Use of Polymer Floods for Heavy Oil Enhanced Oil Recovery (EOR).”

The objective of the project is to improve the oil recovery efficiency by polymer flooding in the Schrader Bluff heavy oil reservoir on the ANS. Polymer flooding has been widely applied to decrease the driving phase mobility and improve the sweep efficiency for conventional oil reservoirs. Recent theoretical results and field results have proved the effectiveness of this technology in viscous and heavy oil reservoirs. The current field pilot tests of the project also have shown encouraging results in the EOR performance of polymer flooding.

Many laboratory experiments and simulation studies have been conducted to understand the mechanisms behind the optimistic results in pilot tests in different environments. This paper will focus on the effect of polymer rheology on polymer flooding performance in ANS heavy oil reservoirs that are developed with horizontal well.

The use of horizontal wells for EOR in heavy oil reservoirs has increased in recent years. As the target formations in the ANS are relatively close to permafrost, steam generation is prohibitive considering the heat loss and environmental requirements. Thus, polymer flooding has been recommended and applied in the target heavy oil formation.

Although many simulation studies have been conducted on the rheology model effect of polymer flooding, the results are for the vertical well system and lack applicability for the current horizontal well projects. Thus, to examine the rheology model effect on polymer flooding efficiency with the horizontal well system in heavy oil reservoirs, the project demonstrates how hydrolyzed polyacrylamide (HPAM) apparent viscosity correlated with polymer concentration, formation permeability, porosity, saturation condition and flow velocity. A large variation of formation heterogeneities (K ratio ranges from one to 50) was considered for sensitivity analysis. Incremental oil recovery, water cut reduction, injection profile improvement and water-oil ratio (WOR) also were considered to examine the polymer flooding efficiency.

Simulation model description

To reduce the noise of other influencing factors and to analyze the detail effect of polymer rheology modeling on the polymer injection profile, sweep and oil recovery, all simulation runs were conducted in an areal conceptual model containing two horizontal laterals—an injector and a producer.

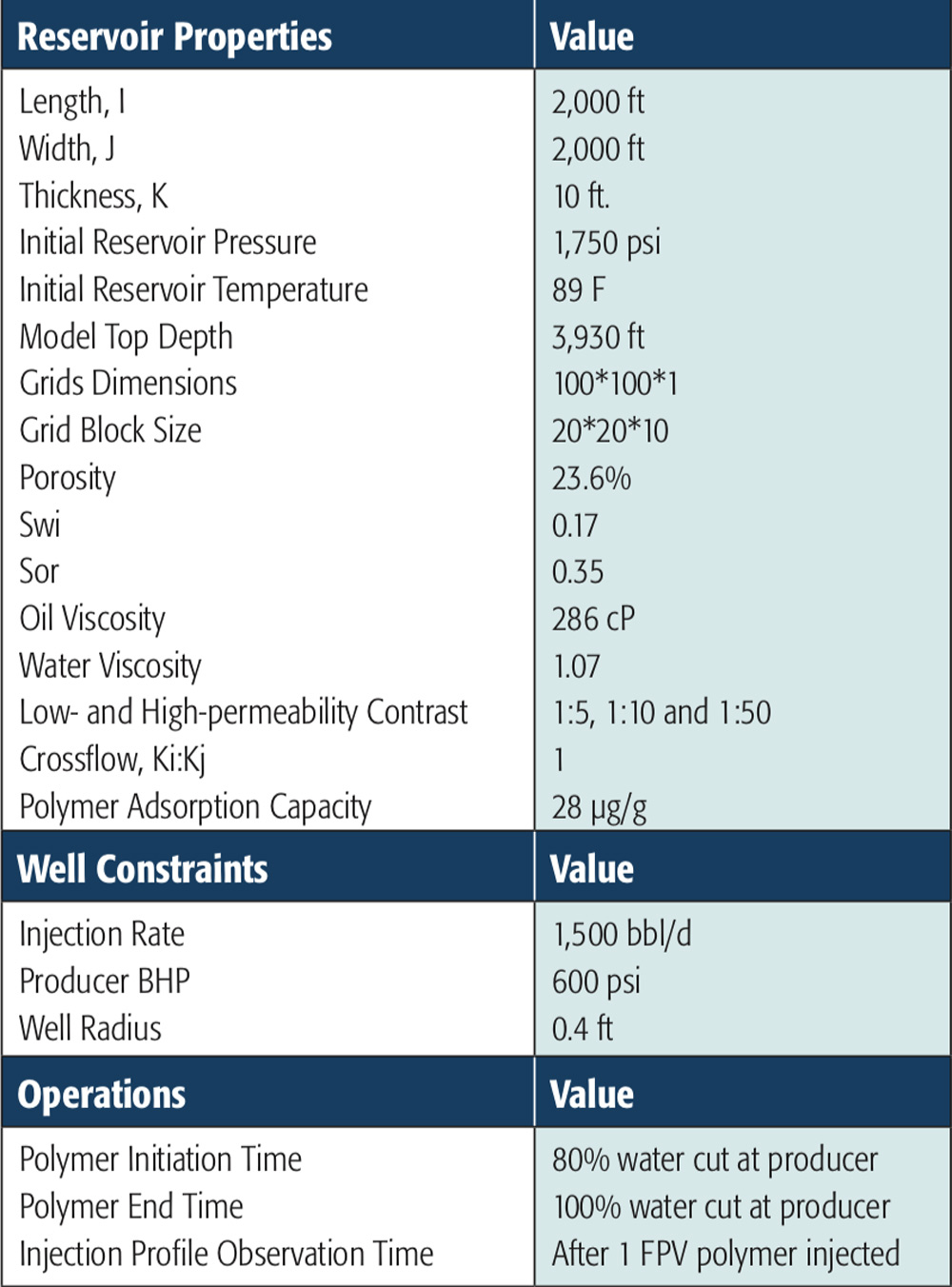

The horizontal model is located at 3,930 ft true vertical depth. The model contains a vertical high-permeability channel extended from injector to producer. Thus, the model contains two different permeabilities. The reservoir characteristics are listed in Table 1. The relative permeability was measured by laboratory experts using sandpack coreflooding from Schrader Bluff NB Formation.

Laboratory experts also measured a residual resistance factor of 1.4 (ratio of core permeability before polymer and after polymer flooding), which was caused by polymer adsorption. However, in this study, because the adsorbed polymer is not expected to interfere with the effect of polymer rheology, it is assumed the polymer adsorption does not reduce permeability significantly.

Simulation design

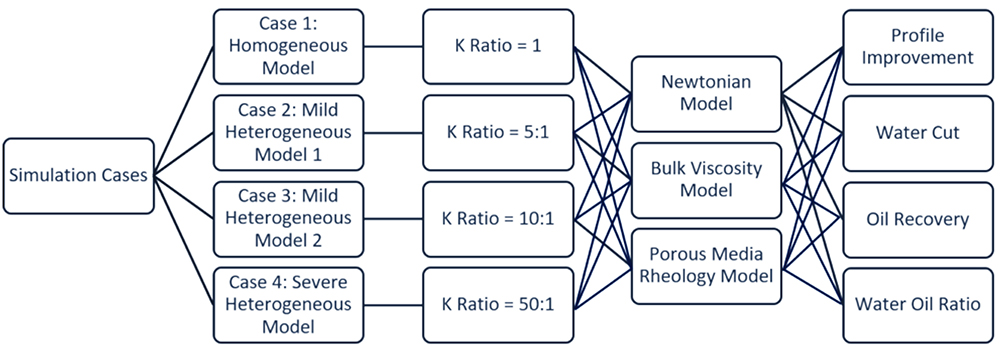

In a homogeneous reservoir, medium to high shear rates usually only exist near the wellbore. In a heterogeneous reservoir, shear rates also can elevate greatly in high-permeability zones or channels. As a result, this study implemented four heterogeneity cases for each rheology model, Figure 1.

The study discussed the polymer flooding simulation while considering the rheology influence in horizontal wells. Consistent with previous theoretical analysis, the simulation results presented the variations of polymer flooding efficiency by using the bulk viscosity model and the apparent viscosity model at relatively high flow rates with the linear flow in parallel horizontal well systems. The sweep was largely increased if the shear thickening was considered in the rheology model. Simulation of HPAM non-Newtonian rheology using bulk viscosity can greatly underestimate the prediction results of real porous media performance of polymer flooding, and application of the apparent viscosity model shows great benefit for this case study of heavy oil polymer flooding using horizontal wells in terms of profile control, sweep improvement and WOR reduction.

Simulation results for this case study

The apparent viscosity response can provide sufficient resistance for the driving phase in channels where velocity is commonly very high but keep a moderate resistance in matrices where velocity is relatively lower. With this mechanism, the apparent viscosity model makes HPAM polymer eligible for conformance control in horizontal well polymer flooding.

Secondly, polymer flooding effectiveness was strongly influenced by reservoir heterogeneity.

In addition to the optimal recovery stage by waterflooding in heavy oil, polymer flooding can provide an extended period of optimal recovery with low WOR. For higher heterogeneity cases, this extended period was very limited for the bulk viscosity model but increased dramatically for the apparent viscosity model.

Lastly, the application of the apparent viscosity model in simulation shows significant benefit for the case study in heavy oil polymer flooding using horizontal wells to improve the sweep, reduce the WOR, overcome the negative effect by heterogeneity and extend the economic production.

Editor’s note: This article is a condensed version of “Impact of Rheology Models on the Injection Profile and Recovery Improvement of Horizontal Well Polymer Flooding in a Heavy Oil Reservoir on Alaska’s North Slope: A Simulation Study,” submitted to the U.S. Department of Energy’s National Energy Technology Laboratory. More information on the project can be obtained at netl.doe.gov.

Recommended Reading

Seadrill Awarded $97.5 Million in Drillship Contracts

2024-01-30 - Seadrill will also resume management services for its West Auriga drillship earlier than anticipated.

TPH: Lower 48 to Shed Rigs Through 3Q Before Gas Plays Rebound

2024-03-13 - TPH&Co. analysis shows the Permian Basin will lose rigs near term, but as activity in gassy plays ticks up later this year, the Permian may be headed towards muted activity into 2025.

US Drillers Add Most Oil, Gas Rigs in a Week Since September

2024-03-15 - The oil and gas rig count, an early indicator of future output, rose by seven to 629 in the week to March 15.

US Drillers Add Most Oil Rigs in a Week Since November

2024-02-23 - The oil and gas rig count rose by five to 626 in the week to Feb. 23

US Drillers Add Oil, Gas Rigs for Third Time in Four Weeks

2024-02-09 - Despite this week's rig increase, Baker Hughes said the total count was still down 138 rigs, or 18%, below this time last year.