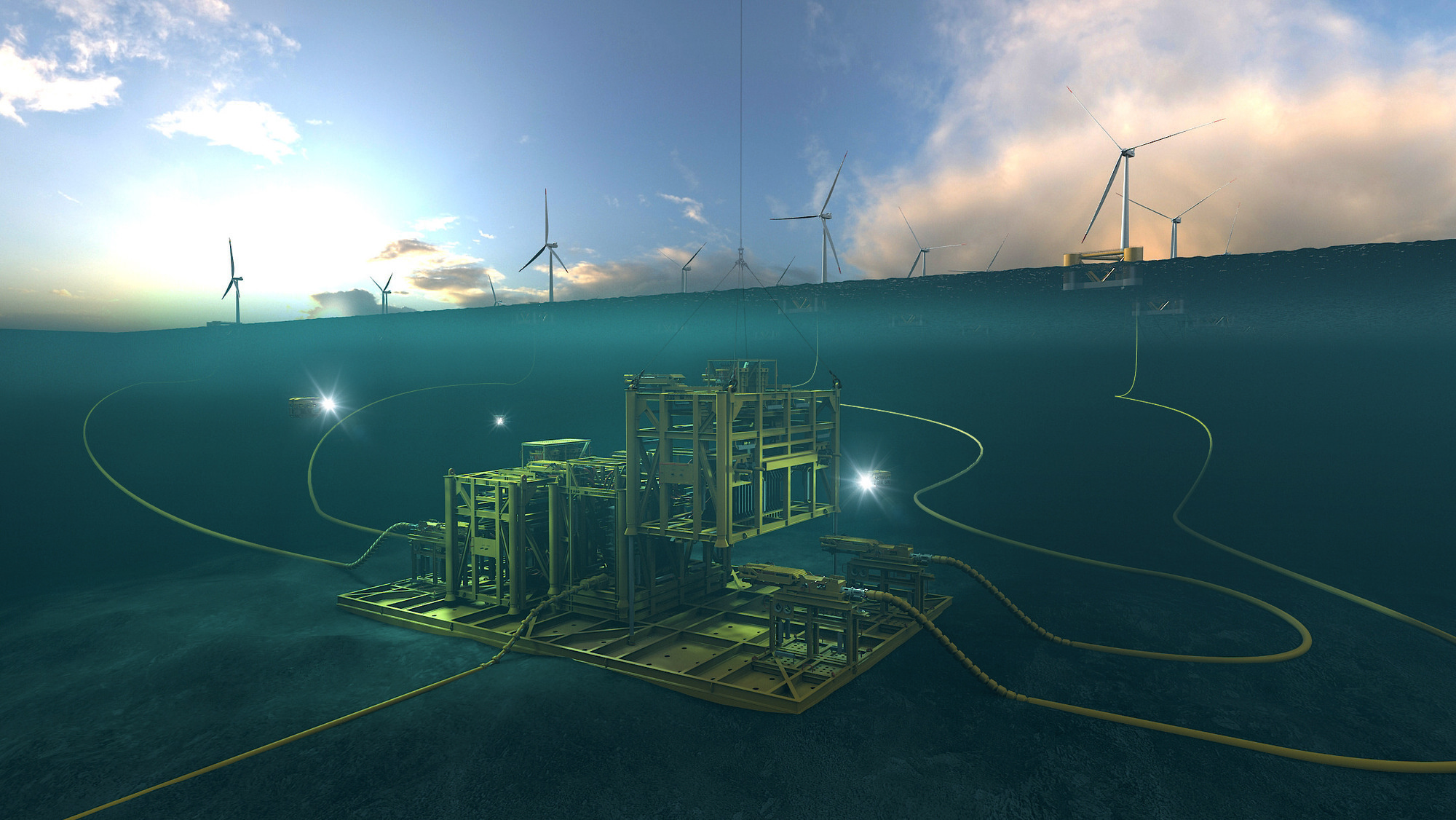

(Source: Aker Solutions)

[Editor's note: A version of this story appears in the July 2020 edition of E&P. Subscribe to the magazine here. It was originally published July 1, 2020.]

The COVID-19 economic shock has reinforced the need for diversification for companies across the globe. The oil market’s collapse has created an environment where oil and gas companies are now being compelled to expand into adjacent infrastructure markets with bright horizons like offshore wind.

Offshore wind market summary

Market dynamics are quickly positioning offshore wind for growth. As oil prices continue to drop, wind now generates more electricity than hydropower and is a primary reason why generation from renewables regularly outpaces output from coal. The market for wind power is expected to grow about 7.9% during the forecast period of 2020 to 2025. Offshore wind capacity is expected to increase 15 times over, becoming a $1 trillion industry by 2040, according to the International Energy Authority. Favorable government policies, increasing investment in wind power projects, the demand for renewables in relation to climate change and the reduced cost of wind energy is increasing demand.

The specific attractiveness of offshore wind projects are also in part due to stronger more predictable wind, fewer HSE risks and generally less resistance from local communities. Offshore wind is truly a “not in my backyard” solution.

Where offshore wind is now

Offshore wind development is more mature in Europe, and European energy companies like Equinor have become very active in its development. In the U.S., turbines started spinning on the first offshore wind energy farm powering a U.S. community in Block Island, Rhode Island. That number is expected to grow quickly as offshore wind developers are lining up to build the first wind turbines off the coast of California as well.

Despite the emerging opportunity, there are still many challenges that need to be overcome. These challenges include design, construction and sustainment.

Offshore wind solutions marry the complexity of 500-plus-ft tall land-based wind turbines and the ocean, earth’s most dynamic and powerful force. The vendors familiar with these previously separate engineering challenges must come together to fuse the most resilient and efficient solutions. Prototyping is prohibitively expensive and dangerous due to the realities of the offshore environment. Digital simulations must be leveraged to minimize this risk and increase profitability during project design.

Wind developers looking to exploit the benefits of offshore expenses will face the same marine realities that offshore oil and gas suppliers have been conquering for nearly 100 years. Who better to partner with wind engineering experts to lead offshore wind projects from feasibility to construction?

A rush of investments and production of wind energy also is driving a steep increase in operations and maintenance (O&M) spending. In fact, it is estimated that annual O&M spending in the wind industry will reach $7.5 billion in 2030, up 50% from 2018. As with a neighborhood gym, revenue growth at a wind farm is accompanied by increased wear and tear. After the initial investment, the primary driver of profitability is optimizing maintenance costs. This makes smart maintenance a big driver for profitability throughout a project’s life cycle.

Overall, current offshore projects are also not consistently providing the performances that the models predicted. Understanding of large-scale offshore wind farms is still new, and there are many gains to be made by optimizing engineering, placement and operations.

Addressing the challenges

Offshore wind does not yet have the digital infrastructure to address these challenges because the data exist in silos, with no data sharing between vendors or operators. Operators do not have the necessary tools to operate assets in an optimal way.

Therefore, the industry must fully implement digitalization by liberating and contextualizing existing data to empower remote operations, optimize maintenance and lower life-cycle costs. The ability to harness data by liberating it and contextualizing is already transforming oil and gas efforts and will continue to do so while helping to provide solutions for the new energy landscape.

For instance, DataOps/Fusion connects maintenance records and engineering drawings to full context views of operational data from a fleet of assets, allowing supervisors to remotely optimize maintenance campaigns within the fleet.

It is widely known that data models can be used to move from a preventive maintenance routine where parts are needlessly replaced at a predetermined frequency toward a predictive maintenance routine where parts are replaced just in time before an impending failure. What is not commonly admitted is that these models often fail to scale due to the physical complexity of the assets, the reliance on siloed data and the overfitting of models on a small number of failures.

Investments in DataOps will allow wind operators to more scalably extract value from their data by viewing it holistically, modeling it comprehensively and scaling their proofs of concepts wins to returns.

Overall, digitalization can provide significant cost savings in the asset life-cycle costs by collecting data from concept to operation. This allows data to be shared and consumed by everyone that can contribute to such assets being built and used in the absolute most optimal way. This is how you can scale the business and establish sustainable business processes.

Next-generation digital wind solutions

Cognite and Aker Solutions recently received a grant from the California Energy Commission to focus on next-generation solutions in wind through digitalization and aims to develop a holistic digital solution that will enable monitoring the condition of an offshore floating wind farm and its impact on the environment via live data streaming.

One of the digital solutions Cognite plans to bring to this project is the use of digital twins. For example, offshore wind has a unique set of challenges, in that the turbine, similar to a land-based turbine, is just one component of the overall asset. Therefore, a digital twin must be considered and should include the turbine atop the structure, the moorings, the currents and ever-present threat of indomitable weather events.

Floating offshore wind infrastructure is a relatively nascent exploration due to its exponentially complex operating conditions. In spite of these challenges, intrepid plans are underway to support renewable energy goals where waterborne wind is readily available but depths are too great for seabed secured turbines.

Though a few prototypes exist, there are limited real sources of data available to comprehensively study the reality of offshore floating wind. It is therefore warranted to simulate this with Cognite Data Fusion, which will result in

- Remote data access that will drive decisions 20 miles offshore;

- Operations support enable onsite workers to have all relevant data at their fingertips; and

- Digital twins, remote monitoring and empowering current workers with new digital tools that will drive value and impact.

Case study

Cognite has recently used digital twins to address maintenance and optimization. For one customer, Cognite built a comprehensive digital twin of its offshore production assets then operationalized the previously siloed industrial data. This powerful digital twin fuses 3D design models, live-streaming time series data, design documentation, maintenance data and more to create a digital representation.

This technology has quickly enabled 50-plus applications that target individual production optimizations and maintenance cost saving use cases that will capture more than $70 million per year in estimated value by year-end 2020.

Energy industry leaders must invest and adapt in digital technologies as the market will be increasingly dynamic with advantages going to the organizations that most adequately leverage data and digital through innovative technology. Energy companies must anticipate challenges, unlock profitability, and empower and upskill workers with digital tools to compete and harness this new leader in energy.

Recommended Reading

Novo II Reloads, Aims for Delaware Deals After $1.5B Exit Last Year

2024-04-24 - After Novo I sold its Delaware Basin position for $1.5 billion last year, Novo Oil & Gas II is reloading with EnCap backing and aiming for more Delaware deals.

Enverus: 1Q Upstream Deals Hit $51B, but Consolidation is Slowing

2024-04-23 - Oil and gas dealmaking continued at a high clip in the first quarter, especially in the Permian Basin. But a thinning list of potential takeout targets, and an invigorated Federal Trade Commission, are chilling the red-hot M&A market.

EIA: Permian, Bakken Associated Gas Growth Pressures NatGas Producers

2024-04-18 - Near-record associated gas volumes from U.S. oil basins continue to put pressure on dry gas producers, which are curtailing output and cutting rigs.

Benchmark Closes Anadarko Deal, Hunts for More M&A

2024-04-17 - Benchmark Energy II closed a $145 million acquisition of western Anadarko Basin assets—and the company is hunting for more low-decline, mature assets to acquire.

‘Monster’ Gas: Aethon’s 16,000-foot Dive in Haynesville West

2024-04-09 - Aethon Energy’s COO described challenges in the far western Haynesville stepout, while other operators opened their books on the latest in the legacy Haynesville at Hart Energy’s DUG GAS+ Conference and Expo in Shreveport, Louisiana.