A North Sea operator deployed the Quest GWD system with two survey specialists monitoring real-time well and survey data from a remote operating center onshore in Aberdeen, which Gyrodata said eliminated the need for additional personnel on the rig. (Source: Shutterstock.com)

The challenges of properly drilling and placing wellbores are many, especially in offshore projects where difficult environmental conditions and complex well design necessitate incorporating more advanced technology into traditional BHA configurations. The North Sea is no exception to this, as implementation of wired drillpipe and more accurate downhole sensors is placing information at operators’ fingertips at record speed. An operator can only do so much to place an accurate well and mitigate the risk of wellbore collision, however, without implementing a proper surveying system.

Early surveying technology, which used spinning-mass gyros to allow while-drilling trajectory verification, has been available commercially for decades. These gyro-while-drilling (GWD) systems, though still relevant today, are not always viable in harsher downhole environments, driving the development of a new system based on solid-state gyro technology. The Quest GWD system, introduced by Gyrodata, is a first-of-its-kind innovation in wellbore surveying that is powered by more accurate, more rugged sensors, answering the oil and gas industry’s call for a system that will improve efficiency while offering cost and implementation benefits over previous offerings. In the North Sea, the new system has seen tremendous uptake by operators recognizing that better survey quality ultimately means better reservoir placement and reduction in operational cost.

Technology

Quest GWD is designed to reduce wellbore surveying time and the ellipse of uncertainty. The system incorporates Gyrodata’s new solid-state SPEAR sensors, which are based on Coriolis vibratory gyroscope technology. The sensing element is driven to oscillate at a precise frequency and amplitude, and when rotated about its input axis, a secondary motion perpendicular to the primary motion is created. The amplitude of the secondary motion is proportional to the rotation rate seen by the sensor.

The solid-state SPEAR sensor probes measure the earth’s rotational rate precisely and accurately at any latitude and can handle harsher downhole environments more effectively than conventional, spinning-mass gyroscopes. The system is not affected by mass unbalance errors, which eliminates post-run calibrations, and it allows in-collar load-out, simplifying operations and tool deployment. The system’s shorter sensor package and electronics compared to previous offerings also enable greater flexibility related to sensor positioning in different bottomhole assembly (BHA) designs and configurations.

Case studies

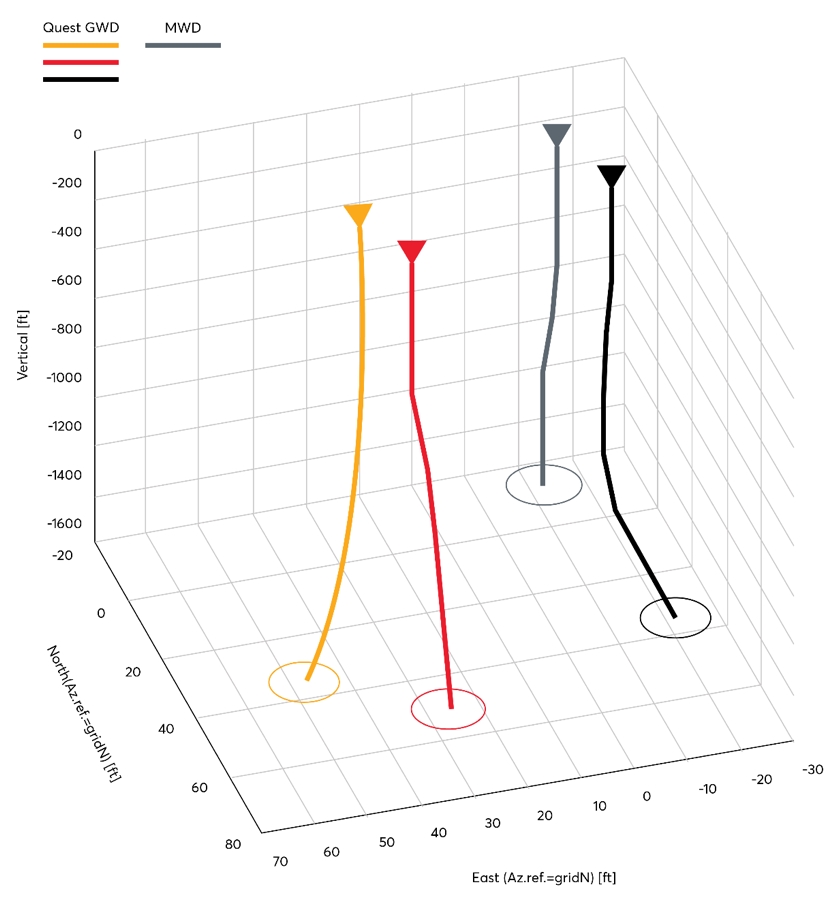

An operator in the North Sea was batch drilling four wells from a jackup rig. The four tophole sections were to be completed collectively, rather than drilling one well at a time, to improve efficiency. Each well was to be drilled vertically before kicking off at approximately 1,200 ft to between 4 and 6 degrees of inclination by total depth (TD). This nudge in varying azimuthal directions would ensure that drilling could achieve optimized separation factors and reduce wellbore collision risks between the four wells (Figure 1). The operator decided to implement the Quest GWD system with the third-party service company’s full directional package to deal with expected magnetic interference and take remote, high-accuracy surveys to assist with gyrosteering while drilling.

The Quest GWD system served as the primary source of directional control and was successfully run inside the service company’s collar to streamline BHA handling on the rig. The operation was carried out entirely remotely with both day and night crews onshore, reducing carbon footprint. Fully remote operations also removed personnel from high-risk zones offshore, providing an immediate HSE benefit and reduction in carbon footprint. By using the same tools and equipment more efficiently with less risk of having to rig down and rig up BHA components, the operator also eliminated several hours of additional rig time. Remote operations eliminated mobilization and logistics costs, while the system’s solid-state sensors enabled a reduction in survey times versus conventional gyro tools. The Quest GWD system’s dramatically increased battery life allowed it to remain in a fully built, shutdown state for longer and mobilized offshore fully made up, meaning no onsite personnel were necessary to finalize rig-up.

In another project, a North Sea operator needed to orient and set their 13⅜-inch whipstock from vertical to mill out a window for sidetracking from a semisubmersible rig during drilling of an exploration well. The operator agreed to implement fully remote survey services and performance monitoring to reduce the need for offshore crews, as well to mitigate the ongoing financial and logistical challenges associated with personnel mobilization during the ongoing COVID-19 pandemic. It was critical that the operator use a survey system that could function effectively during vessel heave so that they could successfully orient and set the whipstock.

The operator deployed the Quest GWD system with two survey specialists monitoring real-time well and survey data from a remote operating center onshore in Aberdeen, eliminating the need for additional personnel on the rig. The remote system improved HSE on the rig and eliminated the costs and logistics of personnel transport and accommodation. The extended GWD mode was programmed with a survey delay to allow maximum data reliability while operating in challenging tophole conditions where sea movement can affect data quality. In addition, the operator was limited to only five pump cycles to achieve setting the whipstock. The operation was completed in just three surveys and all survey data fully passed QC, validating the successful orientation and setting of the whipstock despite the vessel heave during the winter storms.

Conclusion

The oil and gas industry will continue to face difficulties moving forward but understanding wellbore placement need not be one of them. The time when the only possible method of taking surveys in harsh downhole environments was with MWD tools has passed, with the advent of solid-state gyro technology providing the industry with a new way of obtaining highly accurate, reliable, and efficient wellbore surveys. As the ways in which people live and work fundamentally alter how the industry operates, finding ways to reduce carbon footprint, implement better technology and intelligently use available resources will be critical. It will be up to forward-thinking companies and innovators to position the industry to overcome these challenges and achieve future success.

Recommended Reading

Reactive Downhole Tools Appoints COO, CTO

2024-02-14 - Reactive Downhole Tools is also developing a new R&D test center in Abu Dhabi.

SunPower Begins Search for New CEO

2024-02-27 - Former CEO Peter Faricy departed SunPower Corp. on Feb. 26, according to the company.

First Solar’s 14 GW of Operational Capacity to Support 30,000 Jobs by 2026

2024-02-26 - First Solar commissioned a study to analyze the economic impact of its vertically integrated solar manufacturing value chain.

Daniel Berenbaum Joins Bloom Energy as CFO

2024-04-17 - Berenbaum succeeds CFO Greg Cameron, who is staying with Bloom until mid-May to facilitate the transition.

GE Vernova Completes Spin-Off from GE

2024-04-04 - GE Vernova, an energy transition company, began trading as an independent company on the New York Stock Exchange this week.