A 3D point cloud structure-from-motion model can be generated in near-real time onboard the vessel using footage from imagery to provide an enhanced understanding of features. (Source: i-Tech 7 and Leidos)

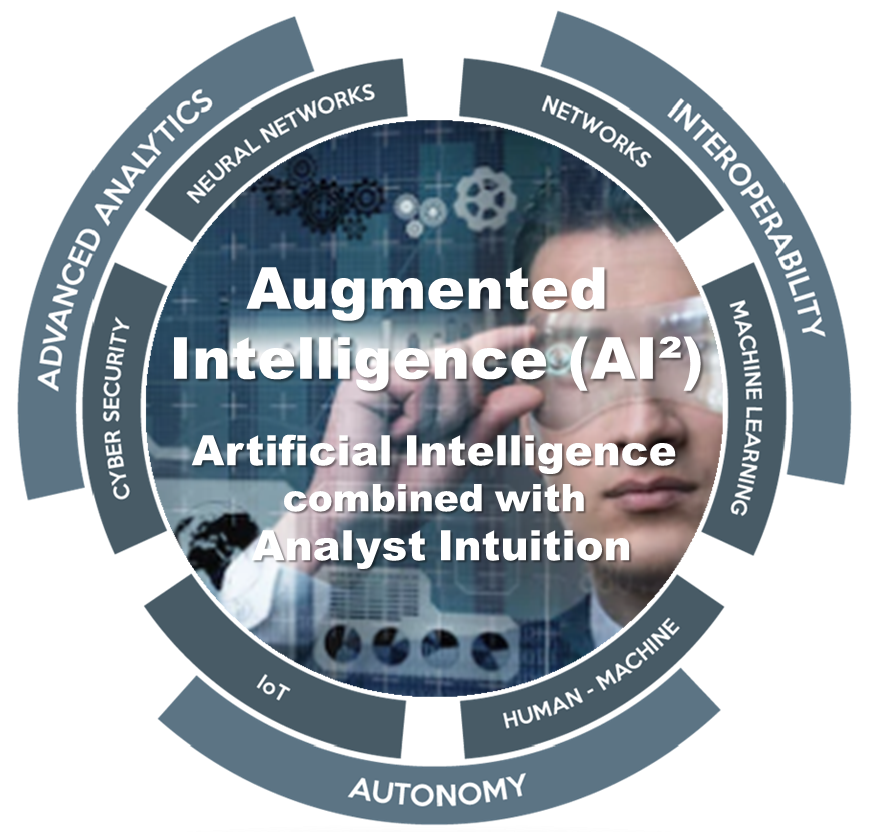

As powerful and fast as computers can be, in isolation, artificial intelligence (AI) tools are of limited value without the guidance, intuition and expertise of humans, especially when it comes to defining the problems to be solved. Augmented intelligence is the fusion of AI and analyst intuition and represents the computer and its human operators (analysts) working in harmony using superior processes.

According to analysts, AI augmentation is expected to create $2.9 trillion of business value globally and 6.2 billion hours of worker productivity within two years. It will surpass all other types of AI initiatives by 2030 to account for 44% of the global AI-derived business value.

To realize these benefits and deliver on such high expectations, augmented intelligence relies on the existence of three tightly integrated capabilities: autonomy, advanced analytics and interoperability. Together, these facilitate autonomous or semi-autonomous responses to the operational environment and provide human analysts and operatives with greater real-time insight than ever before.

For subsea, the deployment of increasingly capable AUVs and autonomous surface vessels is becoming more widespread. As in other industries, the adoption of augmented intelligence can transform subsea activities and business processes.

To closely link all aspects of the data workflow, within the context of delivering the data and harvesting additional insight and value, i-Tech 7 and Leidos approached the challenge via two principal directions:

• Through the application of autonomous systems for data acquisition and delivery, thereby reducing vessel reliance; and

• By automating the acquisition and processing of data and maximizing the insight provided by the data.

Applying augmented intelligence

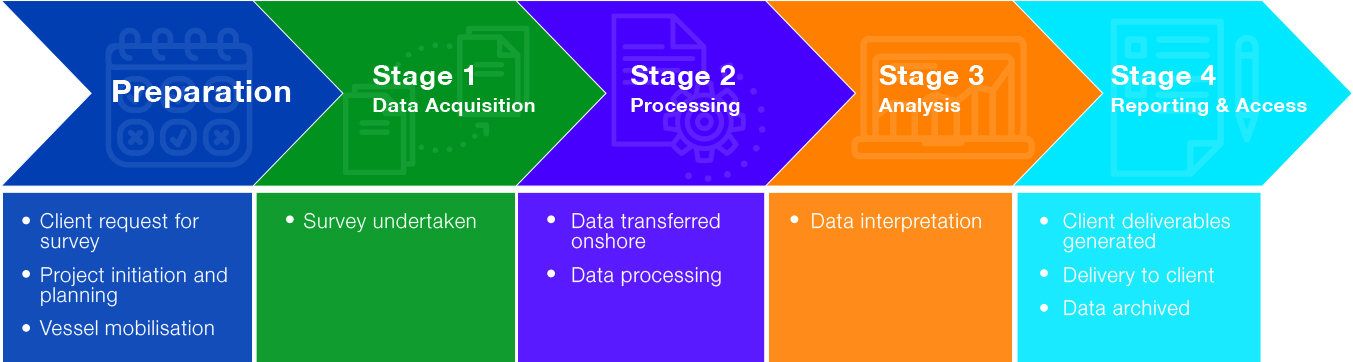

Broadly, the existing subsea inspection process follows a similar set of steps depicted in the figure below. While being a tried and tested business process, much reliance exists at each stage on manual effort to ensure results, with little automation or standardization applied.

The high-level stages depicted in this figure remain mostly unchanged in terms of their order and general flow. However, many of the underlying ROV or AUV activities, for example, involved at each stage can be transformed by augmented intelligence to increase efficiencies and quality, reduce costs and save time.

Transforming subsea inspection

In the preparation of a project, human input is the critical element. The main emphasis is to ensure that automation applied to quality checks augments and enhances the human activity elements of project setup. This can reduce repetitive tasks and minimize errors/rework and inconsistencies, thereby enabling faster and more accurate completion of this stage. For example, in mission planning, the use of smart logistics and campaign planning enables algorithms to optimize resource utilization, sequencing and route proposal. AI also can be used to define smart retrieval of existing and historical data relevant to the scope of the campaign with algorithms applied to enrich the data provided to the operator for quality control and validation.

Stage 1: Data acquisition. Depending on the size and complexity of the campaign, the end-to-end survey process averages about 90 to 120 days in duration. This involves significant amounts of capital-intensive days at sea before results are delivered to the client. During data acquisition, the use of augmented intelligence elevates the focus of the human operative from data capture to ensure the campaign is delivered right the first time and at the highest possible quality. Additionally, the real-time analysis provided by augmented intelligence allows the detection of critical events far earlier in the campaign. This means that any necessary decisions/interventions can be resolved while the vessel and ROV/AUV is in situ. The machine will become a more reliable observer of change and/or new features. This will free up the operator to concentrate on critical elements and overall efficiencies.

Stage 2: Processing. Most activity in the traditional processing stage centers on the labor-intensive, time-consuming video review activity. With the aid of augmented intelligence, significant amounts of this type of effort and repetitive work can be automated and streamlined across tasks such as navigation processing and data synchronization. In addition to delivering a vastly accelerated process, augmented intelligence allows experts to concentrate on producing the highest quality results and to generate new insights for clients through intelligently cross-referenced historical datasets. Here, the machine will develop into a superior observation and logging platform.

Stage 3: Analysis. Historically, the analysis stage has been confined to ensuring quality rather than offering any additional insights. Fresh insights through augmented intelligence can be brought to the survey stakeholders earlier than previously possible, which takes the customer closer to near-time inspection activity than ever before. Advanced analytical techniques also allow comparisons to be made with previous surveys, enhancing the basis on which decisions can be made. The use of automated analytics also can detect and depict change over time using historical datasets to identify trends and deliver predictions. It can be used for further in situ investigation, involving the client, to aid future inspection campaign planning. The use of AI will magnify the value of disparate data, aggregating and comparing them to provide notifications for the human interface. The user can assess and articulate high-value insights and recommendations in the knowledge that all the available data have been used in the analysis.

Stage 4: Reporting and access. Finally, augmented intelligence is used to transform and automate the process of collating and providing the results of the survey to the client. This includes process efficiencies whereby the system generates and automatically publishes the report to the client via a self-service portal, which can aid client inspection systems. It can also provide access to high-value data and insights via configurable web-based customer dashboards/GIS front-end. Automation and AI will give a visual portal on various platforms and formats so the client can concentrate on the implications rather than managing and manipulating datasets.

References available. Contact Jennifer Presley at jpresley@hartenergy.com for more information.

Editor’s note: This article is an abridged version of the SPE-29335-MS paper presented at the 2019 Offshore Technology Conference.

Have a story idea for Offshore Solutions? This feature highlights technologies and techniques that are helping offshore players overcome their operating challenges. Submit your story ideas to Executive Editor Jennifer Presley at jpresley@hartenergy.com.

Recommended Reading

Tangled Up in Blue: Few Developers Take FID on Hydrogen Projects

2024-04-03 - SLB, Linde and Energy Impact Partners discuss hydrogen’s future and the role natural gas will play in producing it.

Occidental Reports ‘Great Progress’ on Net-zero Pathway, DAC

2024-02-21 - Most of Occidental Petroleum’s planned $600 million investment in emerging low-carbon ventures for 2024 will go to direct air capture facility STRATOS, CEO Vicki Hollub says.

Exclusive: What’s Needed to ‘Get Things Moving’ with CCS

2024-03-05 - CCS momentum is brewing, says Katja Akentieva, vice president of New Energy Solutions for the Western Hemisphere at TGS. Now it's time to capitalize on that momentum in this Hart Energy LIVE Exclusive with Jordan Blum.

Sabadus: US to Steer Global Energy Markets Amid Clashing Forces

2024-03-14 - Increased geopolitical risk and the shift from fossil fuels to renewables are pulling the world in different directions, and the U.S. will be called to play a significant role in the global tug of war.

‘Unapologetic,’ Barclays Restarts E&P Coverage: ‘The World Needs Oil and Gas’

2024-04-10 - Barclays analysts, in restarting coverage of E&Ps, presented anti-hydrocarbon investors with “a reality check on energy transition.”