The Port of Long Beach in California has unveiled plans for a massive $4.7 billion facility aimed at supporting the development of floating wind in the U.S.

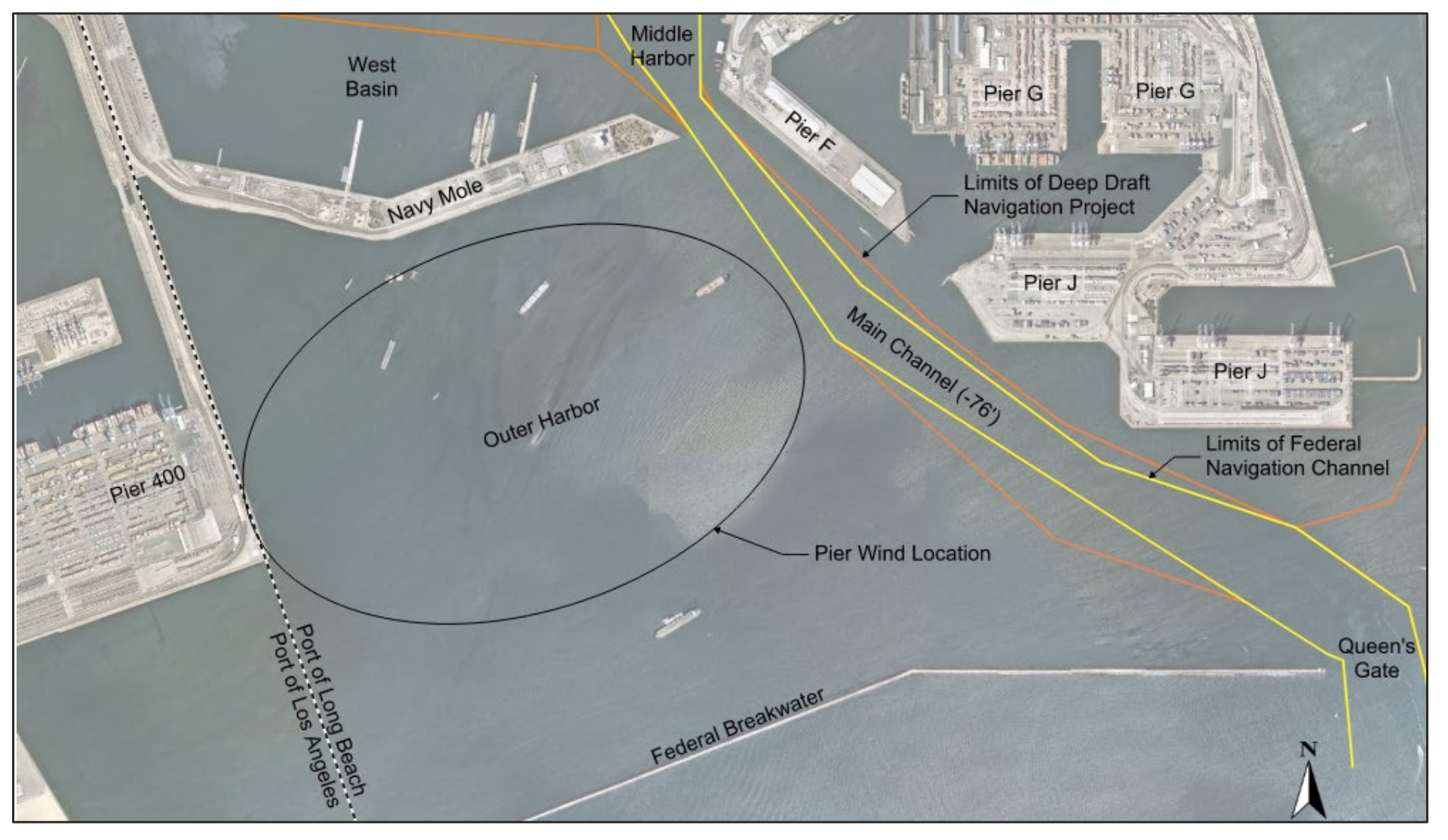

Called Pier Wind, the terminal would span some 400 acres, becoming the largest U.S. seaport designed to accommodate assembly of offshore wind turbines that can be as tall as the Eiffel Tower as well as large foundations.

“Imagine fully assembled wind turbines capable of generating 20 megawatts of energy towed by sea from the Port of Long Beach to offshore wind farms in Central and Northern California,” Port of Long Beach Executive Director Mario Cordero said in a statement.

“As society transitions to clean energy, our harbor is ideally located for such an enterprise – with calm seas behind a federal breakwater, one of the deepest and widest channels in the U.S., direct access to the open ocean and no air height restrictions. No other location has the space to achieve the economies of scale needed to drive down the cost of energy for these huge turbines.”

The plans released May 9 come a few months after the U.S. Bureau of Ocean Energy Management awarded development rights for five wind leases in the nation’s first Pacific Ocean wind ocean. The area’s deep water depths call for floating wind technology. Unlike conventional fixed-bottom wind turbines that are attached to the seabed in shallower water, floating turbines are moored to floating structures. They work the same as other wind turbines: wind pushes the turbine’s blades, causing them to spin and turn the rotor that is connected to a generator.

Getting the floating wind sector up to speed will require infrastructure capable of handling such large equipment with ample laydown space, which is lacking on the U.S. West Coast.

Plans call for deepening and widening parts of the port’s Main Channel, West Basin, Pier J Basin and other improvements, including constructing a new dredge electric substation.

Construction of the phased project could begin in January 2027, the port said. The first 100 acres could become operational in early 2031 with the second 100 acres operational in late 2031 and final 200 acres online in 2035.

Development of floating wind areas offshore California will push the U.S. toward the Biden administration’s goal of deploying 30 gigawatts (GW) of offshore wind energy capacity by 2030 and 15 GW of floating offshore wind by 2035. The action will also move California closer to its ambitions of producing up to 5 GW of electricity from offshore wind by 2030 and 25 GW by 2045.

Energy Storage

Tesla Starts Constructing Lithium Refinery in Texas

Tesla broke ground this week on a $375 million in-house lithium refinery near Corpus Christi, Texas, accelerating its clean energy drive toward electrification of the transportation sector.

The 1,200-acre facility in Nueces County’s Robstown will produce battery-grade lithium hydroxide and be the site of other types of battery materials processing, refining and manufacturing operations for Tesla’s sustainable product line.

The Austin-based company said the facility, which is expected to be completed in 2024 and reach full production in 2025, will be the “first of its kind in North America.” The facility will use an innovative, less energy-intensive process designed to consume less hazardous reagents and create usable byproducts—a mix of sand and limestone that can be used in construction materials—unlike the conventional process that leaves behind sodium sulfate, company executives said during a May 8 groundbreaking event that was streamed online.

“We expect to produce lithium for about a million vehicles and produce more battery-grade lithium than the rest of North American refining capacity combined,” Tesla CEO Elon Musk said at the event as construction rolled in the background.

The EV maker plans to continue using other suppliers of lithium for its batteries, but saw a need to address the availability of battery-grade lithium. Musk called it “fundamental chokepoint” in advancing EVs. Though lithium ore is common, there is a shortage of heavy industry refinement of lithium to battery-grade, he said.

The facility expands Tesla’s footprint in Texas. The company announced in July 2020 the construction of a new EV manufacturing facility in Travis County about a year and half after relocating its corporate headquarters to Texas from California.

Other sites that had been considered for the Robstown plant included one in Louisiana, according to a tax abatement application Tesla submitted last year to the Robstown Independent School District.

“Once complete, the facility will represent an investment of… [greater than $1 billion] in Southwest Texas,” Tesla said in a news release “This investment is critical to our mission to accelerate the world’s transition to sustainable energy and represents our efforts to aggressively increase the supply of battery-grade lithium hydroxide available in North America.”

Geothermal

Wells2Watts Consortium on Track for Demonstration, Testing

The Wells2Watts project underway at the Baker Hughes Energy Innovation Center in Oklahoma is on track for the demonstration and testing phase, having recently received a tubular solution seen as key in the project.

The project is centered on transforming nonproductive oil and gas wells into geothermal energy producers. Led by a consortium of Baker Hughes, GreenFire Energy Inc. and Vallourec, the project is testing an advanced closed-loop geothermal. As explained in a news release, GreenFire’s GreenLoop downbore heat exchanger circulates a working fluid through a sealed tube to absorb heat and return the heat to the surface.

The consortium called delivery of Vallourec’s Thermocase Vacuum Insulated Tubing a “significant milestone.”

“With the comprehensive testing and technology that GreenFire Energy’s GreenLoop and Vallourec’s Vacuum Insulated Tubing solutions bring to the project, we are confident that we can successfully demonstrate the transformation of non-productive oil and gas wells into reliable and sustainable geothermal wells capable of generating renewable electrical power,” said Robert Klenner, advanced geothermal leader at Baker Hughes and executive director of the Wells2Watts consortium.

Premier Corex, Teverra Form Strategic Geothermal Alliance

Houston-based Premier Corex, a rock and fluid testing specialist, has partnered with engineering and geoscience company Teverra to provide engineering and geoscience consulting services to the geothermal energy sector.

The strategic alliance, announced May 12, brings together the skillsets of both companies to provide thermo-hydro-mechanical modeling and design for companies developing large-scale geothermal projects.

“This partnership is focused on providing more robust and impactful solutions for geothermal operators with the integration of high-quality data and value-added data-driven solutions,” Teverra CEO Hamed Soroush said in a news release. “This is required for efficient and reliable development of geothermal resources and will be vital as we scale this baseload energy source.”

Premier Corex’s rock and fluids testing laboratories will be used to generate data for Teverra, a technology and consulting firm, according to a news release.

“Through this strategic alliance, we not only empower these companies to evaluate project feasibility by illuminating the subsurface but also enable our clients to optimize energy potential from these resources in a cost-effective manner,” Premier Corex CEO Randal Wichuk said in the news release.

Hydrogen

ABB, Lhyfe, Skyborn Partner to Develop 600-MW Hydrogen Project

Switzerland-based ABB said May 8 it has partnered with hydrogen producer Lhyfe and offshore wind developer Skyborn to develop a 600-megawatt (MW) hydrogen facility in Sweden.

The SoutH2Port project will produce about 240 tons of hydrogen per day, which ABB said is equivalent to about 1.8 million barrels of oil per annum, making it one of Europe’s largest renewable hydrogen projects. Located in Söderhamn, Sweden, the hydrogen facility will utilize electricity produced by Skyborn’s 1 GW Storgrundet wind farm offshore Sweden.

“By combining our expertise and solutions, we can cost-effectively and safely expand the value creation attached to the scale up of renewable hydrogen production,” said Taia Kronborg, co-founder and chief business officer at Lhyfe. “Skyborn’s track record in offshore wind power, Lhyfe’s expertise in renewable hydrogen production coupled with ABB’s technological expertise creates new opportunities for enabling Power-to-X solutions linked with renewable hydrogen production at scale.”

Hydrogen is expected to play a key role in the transition to lower carbon energy sources as the world tries to reduce emissions. While hydrogen can be used in industrial processes, including lowering the sulfur content of fuels, it can also be used in fuel cells to generate electricity. In addition, energy can be stored as hydrogen to help stabilize power grids.

Developers say SoutH2Port will help decarbonize the Swedish energy system. Sweden aims to have no net greenhouse-gas emissions by 2045.

ABB’s role in the partnership will focus on the integration of hydrogen and electricity production using automation, electrical and digital technologies. The company is also looking to incorporate Power-to-X opportunities, converting electricity from renewables into carbon-neutral energy carriers.

“Creating a seamless supply chain, through partnerships such as these, is essential to accelerate the energy transition,” said Brandon Spencer, president of ABB Energy Industries. “Hydrogen plays a crucial role in helping achieve the world’s climate goals when it comes to decarbonizing the industrial and transportation sectors.”

The SoutH2Port project will utilize electricity produced by Skyborn’s 1-GW Storgrundet wind farm offshore Sweden. (Source: ABB)

ADNOC, Baker Hughes Partner to Advance Hydrogen Technology

ADNOC and Baker Hughes said May 10 that they will work together to study and pilot deployment of the energy services company’s technology to produce green hydrogen and graphene at scale.

The partnership comes as ADNOC builds on $15 billion in committed decarbonization projects by 2030. The firms will explore the application of three emerging technologies. As stated in a news release, these include:

- Piloting electrolyzer technology from Nemesys to explore installation and operation of an electrolyzer at the ADNOC Research and Innovation Center;

- Field testing methane plasma technology from Levidian to capture carbon in the form of high-quality graphene and hydrogen; and

- Testing the use of Ekona Power’s growth stage methane pyrolysis technology.

“The unique properties of graphene make it a promising agent to help decarbonize a variety of hard-to-abate sectors while hydrogen can serve to accelerate decarbonization as it does not generate any carbon emissions at point of use,” Musabbeh Al Kaabi, ADNOC executive director of low carbon solutions and international growth directorate, said in the release. “Across ADNOC, we are proactively pursuing a strategy to accelerate the production and deployment of low-carbon and renewable hydrogen.”

ABS Explores Near-Shore Green Hydrogen Production in Korea

Efforts are underway to determine the feasibility for a near-shore floating platform of green hydrogen production and liquefaction in Korea as industry players team up with academia.

ABS said May 9 it has joined the Korea Institute of Energy Technology; HD Korea Shipbuilding and Offshore Engineering, part of HD Hyundai Group; Linde Korea; and Linde PLC in signing an agreement to explore the opportunity.

The feasibility study will be included in a report from South Korea’s Jeolla Province, according to a news release.

Solar

Edison Next to Build 7.1 MWp Photovoltaic Plant in Italy

Edison Next signed a 20-year onsite power purchase agreement contract with Berco on May 5 to design, construct, manage and maintain a ground-mounted photovoltaic (PV) plant for Berco’s Copparo site in the Province of Ferrara, Italy.

The plant will have a capacity of about 7.1 megawatt-peak and will cover a total area of 96,000 sq m. It will consist of 70 inverters and 11,600 PV modules.

The plant will generate approximately 11,000 megawatt-hours (MWh) per year, covering 9% of the plant’s electricity needs through renewables. The share of self-consumption of renewable electricity self-produced by Edison Next — and destined for the Copparo site — will be just over 80%, with the remainder being stored or fed into the grid.

"Photovoltaics is a mature, consolidated and reliable technology that ensures benefits in terms of energy and emission reductions, and increases grid independence, limiting exposure to price volatility," said Marco Steardo, director of industry at Edison Next. “Today, it is the key technology from which to start on the path to decarbonization."

According to Patrick Buchmann, CEO of the ThyssenKrupp forged technologies business unit that Berco is part of, the cooperation with Edison Next will significantly contribute to the steps they have taken at the Copparo plant to achieve ThyssenKrupp's 2030 emission reduction targets.

Edison Next is an Edison Group company focused on decarbonization and the energy transition. Berco is a ThyssenKrupp Group company specializing in the manufacture of undercarriage components and systems for tracked, earthmoving machinery and equipment.

Wind

Ireland Awards Contracts in Country’s First Offshore Wind Auction

Four contracts have been awarded to companies looking to develop wind energy offshore Ireland after the country held its first offshore wind power auction.

Provisional results from May 11 show the contracts were awarded to the 1.3-GW Codling Wind Park, being developed by the EDF Renewables and Fred Olsen Seawind joint venture; RWE’s 824-megawatt Dublin Array; the 500-MW North Irish Sea Array (a partnership between Copenhagen Infrastructure Partners and Statkraft); and Corio Generation’s 450-MW Sceirde Rocks Offshore Wind Farm.

Combined, the projects—three off Ireland’s east coast and one off the west—could generate up to 3 GW, enough to power 2.5 million homes.

The projects were awarded at a weighted average strike price of 86.05 euros per MWh. Results surpassed expectations, according to Energy Minister Eamon Ryan.

“This is not just a good result for consumers — it’s also an indication of the confidence that experienced developers have in the potential of the Irish off-shore market,” Ryan said in a Twitter post. “Foreign direct investment will be attracted by this signal of abundant, clean and cheap electricity.”

Two of the projects that qualified were unsuccessful in securing a contract.

Hart Energy Staff contributed to this report.

Recommended Reading

Second Light Oil Discovery in Mopane-1X Well

2024-01-26 - Galp Energia's Avo-2 target in the Mopane-1X well offshore Namibia delivers second significant column of light oil.

BP: Gimi FLNG Vessel Arrival Marks GTA Project Milestone

2024-02-15 - The BP-operated Greater Tortue Ahmeyim project on the Mauritania and Senegal maritime border is expected to produce 2.3 million tonnes per annum during it’s initial phase.

Orange Basin Serves Up More Light Oil

2024-03-15 - Galp’s Mopane-2X exploration well offshore Namibia found a significant column of hydrocarbons, and the operator is assessing commerciality of the discovery.

Oceaneering Won $200MM in Manufactured Products Contracts in Q4 2023

2024-02-05 - The revenues from Oceaneering International’s manufactured products contracts range in value from less than $10 million to greater than $100 million.