Technology developers are making strides when it comes to hydrogen-powered aircraft as the world pushes to lower emissions.

Airbus said this week it is developing a hydrogen-powered fuel cell engine as an option for the zero-emissions aircraft it aims to enter service by 2035.

Marking a world aviation first, Britain’s Rolls-Royce said it has successfully run an aircraft engine on hydrogen.

The tech developments come as Honda gears up to produce a new hydrogen fuel cell electric vehicle (FCEV) based on its Honda CR-V in the U.S.

Here’s a look at some of this week’s renewable energy news.

Batteries

Battery Maker SK On, Hyundai Seals EV Battery Pact

South Korea’s SK On has signed an agreement with Hyundai Motor Group to supply electric vehicle (EV) batteries to factories in North America, the battery manufacturer said Nov. 28.

As part of the agreement, SK On will provide its batteries to Hyundai’s EV plants in the U.S. after 2025 as the automaker works to produce various EV models, the company said in a news release.

“We expect the cooperation between SK On and Hyundai Motor Group to create a big synergy,” SK On Chief Administrative Officer Choi said. “With the latest MOU (memorandum of understanding), both sides can hold a solid position in the process of electrification in the North American auto market.”

To meet requirements of the Inflation Reduction Act in securing lithium, SK On said it recently signed purchase contracts with resource development companies in countries that have signed Free Trade Agreements with the U.S. These, according to the news release, include Australia and Chile.

SK On currently has an EV battery factory in Georgia. The company’s batteries are used on Hyundai’s Hyundai IONIQ 5, IONIQ 6, and Kia EV6.

Natron Energy Lands Investment from United Airlines

Battery manufacturer Natron Energy has secured an investment from United Airlines as it aims to electrify its airport ground equipment such as pushback tractors and gate operations. The strategic equity investment was announced Nov. 30.

“Natron’s cutting-edge sodium-ion batteries presented an ideal opportunity to both potentially expand our sustainability investment portfolio to our ground operations, and to help make our airport operations more resilient,” said Michael Leskinen, president of United Airline Ventures.

About a third of the United’s more than 12,000 pieces of motorized equipment is electric, Natron said, noting its batteries could be used for charging.

“Our batteries provide the high power over short distances that ground service equipment needs,” said Natron Energy CEO Colin Wessells, “and unlike lithium-ion, Natron’s batteries are completely nonflammable and can be safely deployed into ground service operations.”

The company said it plans to use the funds to accelerate production at its Holland, Michigan, manufacturing facility. Mass production at the facility is expected to start in 2023.

Renault-Airbus Partnership to Develop New Generation of Electric Batteries

European planemaker Airbus announced on Nov. 30 a partnership with French carmaker Renault to develop a new generation of electric batteries for cars and planes.

Engineering teams from both companies will join forces to mature technologies related to energy storage, one of the main roadblocks for the development of long-range electric vehicles, Airbus said in a statement.

“For the first time, two European leaders from different industries are sharing engineering knowledge to shape the future of hybrid-electric aircraft,” said Gilles Le Borgne, Renault’s executive vice president for engineering. “Aviation is an extremely demanding field in terms of both safety and energy consumption, and so is the car industry.”

The collaboration will focus on energy management optimization and battery weight improvement while also studying the full life cycle of future batteries and assessing their carbon footprint.

Biofuels/RNG

TotalEnergies Taps Technip for Engineering Work for Grandpuits Project

TotalEnergies has selected Technip Energies for engineering, procurement services and construction assistance as the operator converts its Grandpuits refinery in France into a zero-crude facility, Technip said Nov. 29.

The facility will be capable of producing 210,000 tons per year of sustainable available fuel from feedstock such as used cooking oil and animal fat, according to Technip.

Scheduled to begin production in 2024, the biorefinery will also have processing capacity for about 120,000 metric tons per year (mt/year) of renewable diesel and 50,000 (mt/year) of renewable naptha, TotalEnergies said on its website.

The refinery’s conversion comes as France aims to increase its uses of sustainable fuels. The country has set goals of incorporating 2% biofuel into jet fuel by 2025 and 5% by 2030, the operator said.

Hydrogen

Startup Battolyser Systems Eyes Its First Large-scale Factory

Battolyser Systems, the Dutch manufacturer of an integrated battery and electrolyzer hybrid system, plans to build its first large-scale factory in The Netherlands to help meet demand for green hydrogen and electric storage, the company said Nov. 28.

Located at the port of Rotterdam, the 1-GW per annum Battolyser factory will span 14,000 sq m and cost about €100 million (US$104.6 million) to build, the company said in a news release. The facility would also be home to Systems’ headquarters and R&D center.

“This partnership with port of Rotterdam to develop our first large scale manufacturing facility together is a big step forward in our commercialization,” said Battolyser Systems CEO Mattijs Slee. “The factory allows us to deliver Battolysers at industrial scale and affordable prices. We are in constructive conversation with the Dutch government and EU institutions, and we are confident that together we can secure the required funding.”

A final investment decision on the facility is anticipated by late 2023. If given the green light, the facility would open during second-half 2024.

Called a world first, Battolyser’s integrated battery and electrolyzer system—called the Battolyser—can produce hydrogen from solar and wind when power prices are low and provide electricity to the grid when prices are high, the company said.

“A net zero world will require between 5,000 and 10,000 GW of installed electrolyzer capacity,” Slee said. “The electrolyzer supply chain is a huge opportunity for The Netherlands to develop new sustainable industries that can support our energy transition needs and offer export products to world.”

Honda Gears Up to Produce Fuel Cell EVs in US

Automaker Honda said it will produce a new FCEV based on its Honda CR-V starting in 2024 as it moves to boost global sales of battery EVs and FCEVs to 100% by 2040.

The FCEVs will be produced at the company’s Performance Manufacturing Center in Ohio, Honda said Nov. 30.

“Honda established our goal to realize carbon neutrality by 2050 and the complete electrification of our vehicle lineup by 2040 is critical to achieving it,” said Gary Robinson, vice president of auto planning and strategy for American Honda Motor Co. Inc. “As we accelerate our plan to produce Honda battery EVs in the United States, we also will begin low volume production of fuel cell electric vehicles there to further explore their great potential as part of a sustainable transportation future.”

Rolls-Royce Successfully Tests Hydrogen-powered Jet Engine

Britain’s Rolls-Royce said it has successfully run an aircraft engine on hydrogen, a world aviation first that marks a major step toward proving the gas could be key to decarbonizing air travel.

The ground test, using a converted Rolls-Royce AE 2100-A regional aircraft engine, used green hydrogen created by wind and tidal power, the British company said Nov. 28.

Rolls and its testing program partner easyJet are seeking to prove that hydrogen can safely and efficiently deliver power for civil aero engines.

They said they were already planning a second set of tests, with a longer-term ambition to carry out flight tests.

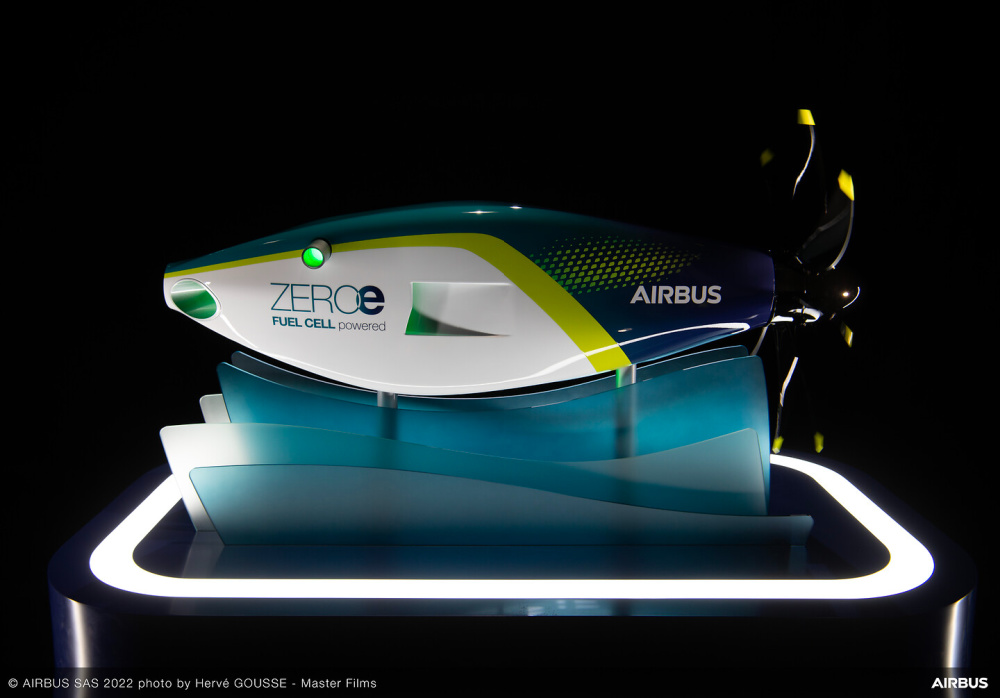

Airbus Creating Hydrogen Fuel Cell Engine for Aircraft

Airbus is developing a hydrogen-powered fuel cell engine as an option for the zero-emissions aircraft it aims to enter service by 2035, the company said Nov. 30.

Ground and flight testing of the engine aboard the demonstrator aircraft will begin toward the middle of the decade, Airbus said, adding the aircraft is being modified to carry liquid hydrogen tanks and associated distribution systems.

“At scale, and if the technology targets were achieved, fuel cell engines may be able to power a 100-passenger aircraft with a range of approximately 1,000 nautical miles,” said Glenn Llewellyn, vice president of zero-emission aircraft for Airbus. “By continuing to invest in this technology we are giving ourselves additional options that will inform our decisions on the architecture of our future ZEROe aircraft, the development of which we intend to launch in the 2027-2028 timeframe.”

Solar, Wind

Octopus Energy Grows Solar Business with Acquisition

Octopus Energy Group’s generation arm has acquired British solar power developer Zestec Renewable Energy to build more than 100 rooftop solar projects, the company said Dec. 2.

Zestec is developing a pipeline of more than 160 megawatts (MW) of solar capacity to allow businesses and public sector organizations to benefit from self-generated renewable power.

Through a fund managed by Octopus Energy Generation, 100-plus projects will be built by 2027. The renewable energy generated will help to reduce emissions and is the equivalent of taking 40,000 petrol cars off the road, Octopus Energy said.

Financial details of the deal were not disclosed.

Saudi’s ACWA, PIF Team Up for 2,060-MW Solar Plant

Saudi developer ACWA Power has partnered with the Public Investment Fund’s (PIF) Water and Electricity Holding Co. (Badeel) to develop what is being called the largest solar power plant in the Middle East, according to ACWA.

The company said Nov. 30 that the 2,060-MW solar photovoltaic plant in Saudi Arabia’s Makkah province is expected to start operations in fourth-quarter 2025, powering about 350,000 homes.

“This marks a key achievement toward PIF’s commitment to develop 70% of Saudi Arabia’s renewable energy by 2030,” said Yazeed A. Al-Humied, deputy governor and head of MENA Investments at PIF. “Utilities and Renewables is one of PIF’s priority sectors as part of its domestic strategy, which focuses on unlocking the capabilities of promising sectors to enhance Saudi Arabia’s efforts in diversifying revenue sources.”

ACWA and Badeel will jointly own the Al Shuaibah 2 facility, each holding a 50% equity stake. The two have signed power purchase agreements to develop the plant. Electricity produced will be sold to the Saudi Power Procurement Company, according to a news release.

ACWA and Badeel are also jointly developing the Sudair Solar PV 1,500-MW project.

Egypt Seals $1.1 Billion Solar, Wind Deal with AMEA Power

The Egyptian government has finalized agreements with Emirati firm AMEA Power to build a solar park and a wind farm with a combined capacity of more than a gigawatt in a $1.1 billion deal, the cabinet said Nov. 30.

The deal provides for AMEA to build a 560-MW solar plant in southern Egypt and a 505-MW wind farm on the Red Sea coast, and is supported with debt and equity financing from the International Finance Corp. (IFC) and several development and commercial banks.

Power from the solar park and the wind farm will be priced at two U.S. cents per kilowatt hour and three U.S. cents per kilowatt hour respectively, the lowest rates in Africa and among the lowest globally, the IFC said in a statement.

Construction of both projects is due to start in December 2022, with completion of the Abydos solar plant expected after 18 months and of the Amunet wind farm after 30 months.

Reuters contributed to this article.

Recommended Reading

Wayangankar: Golden Era for US Natural Gas Storage – Version 2.0

2024-04-19 - While the current resurgence in gas storage is reminiscent of the 2000s —an era that saw ~400 Bcf of storage capacity additions — the market drivers providing the tailwinds today are drastically different from that cycle.

Biden Administration Criticized for Limits to Arctic Oil, Gas Drilling

2024-04-19 - The Bureau of Land Management is limiting new oil and gas leasing in the Arctic and also shut down a road proposal for industrial mining purposes.

PHX Minerals’ Borrowing Base Reaffirmed

2024-04-19 - PHX Minerals said the company’s credit facility was extended through Sept. 1, 2028.

SLB’s ChampionX Acquisition Key to Production Recovery Market

2024-04-19 - During a quarterly earnings call, SLB CEO Olivier Le Peuch highlighted the production recovery market as a key part of the company’s growth strategy.

Exclusive: The Politics, Realities and Benefits of Natural Gas

2024-04-19 - Replacing just 5% of coal-fired power plants with U.S. LNG — even at average methane and greenhouse-gas emissions intensity — could reduce energy sector emissions by 30% globally, says Chris Treanor, PAGE Coalition executive director.