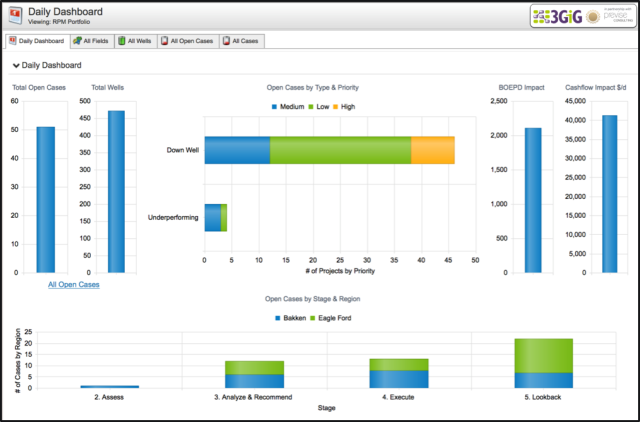

This overview dashboard shows where dissatisfied wells are in the intervention process, demonstrates the business impact and highlights opportunities to adjust people resources in real time. (Source: 3GiG and Previse Consulting)

In year three of lower oil prices, cash is indeed king. Companies are using digital technology to wring every last ounce of value from producing assets. Sensors continuously monitor well operating conditions and send alerts when well behavior is not as expected. Engineers then use sophisticated analytics software to diagnose root causes of dysfunction and develop statistically valid recommendations.

But are companies leveraging digital capabilities to enable humans to deliver excellent execution of those remedial recommendations?

With recommendations in hand, how can digital technology help engineers work with operating personnel and contractors to execute remedial actions in the shortest time possible? Companies have processes for the various well interventions needed, but is each person clear on what they need to do today to return wells to production as quickly as possible? Do process team members have the data and tools necessary to analyze and improve the effectiveness and efficiency of execution activities just as remote operations centers continuously improve well diagnosis?

Accelerating the rate at which wells are returned to production increases cash generated and maximizes asset value. There is an opportunity to combine successful practices found in other industries and use available digital technology such as 3GiG’s “Return to Production” Management (RPM) tool to reduce the time needed to perform remedial activities and get wells back online. RPM creates continuous visibility of wells needing attention, where each well is in the intervention process and who is responsible for which actions to return the well to production. Not only does standardizing and optimizing human activity during the response process increase cash flow, it also allows valuable “human” time to be applied to innovation and process improvements.

3GiG’s RPM tool strengthens an organization’s standard human workflows by capturing and codifying them in a technology platform that can be easily modified for process improvements by the user without the IT department.

A complex challenge

Optimizing intervention in shut-in or underproducing wells is not a new challenge. There are numerous people interactions required, and the ability to reduce the time a well is down is increasingly complex since:

- North American portfolios contain large numbers of operated wells;

- Human and financial resources are limited in the current economic environment; and

- Wells and related infrastructures are aging.

Keeping hundreds or thousands of wells producing as expected tests the limits of even the best engineering and operating teams.

To reduce well intervention time, consider the guiding principles of the retail and financial industries:

- The customer is always right.

- Time is money.

Top performers in other industries recognize where value is created: their customers. When customers receive what they want when they want it, cash registers sing. The most successful companies commit resources every day to the execution of excellent customer service. Adopting these principles for the well intervention process will reduce the time needed to return a well to production and ultimately increase average annual production.

The customer is always right

Most would agree that the point of value creation in the upstream industry is the well. But how many companies treat their wells as customers?

If treating a well as a customer seems outlandish, consider the similarities between human customers and well customers: A person exchanges currency for a product or service. The well offers currency in the form of oil and gas production in exchange for an obstacle-free flow path from the reservoir to the sales meter. When an organization acts quickly to remove any barriers in that fl ow path, the well has received excellent customer service.

To gauge the commitment of a company for offering excellent well customer service, consider what questions are asked at the start of each workday:

- How many wells are down or underproducing today?

- How many wells are in each step of the customer service process (i.e., problem diagnosis, recommendation development, execution of the fix)?

- Who is the “customer service representative” responsible for actions needed today and at every step until the problem is resolved?

If these questions are unasked or unanswered, a company might be leaving barrels in the ground. Companies with excellent customer service recognize that customers should spend as little time as possible in an unsatisfied state. Knowing how many wells are satisfied and how many are not should be a key metric reviewed every day. And an organization’s focus on production surveillance should not be confused with a commitment to providing excellent well customer service.

Time is money

For producing oil and gas fields, well “on-time” is money.

This reality is understood, but few companies measure and track well intervention time as a key metric that infl uences revenue. Answers to the following questions should be common knowledge in the organization:

- What is the average length of time a well is down or underproducing once in distress?

- Is the average length of time trending up or down?

- How often, on average, does a well become dissatisfied, either down or underproducing?

The data required to answer such questions, even if available, often have minimal visibility. Similarly elusive is an understanding of where in the process—problem identification, diagnosis, recommendation development or execution— improvement efforts will deliver the most value.

By treating every well as a customer and measuring key process metrics, daily goals of the well intervention team are clarified: Execute the complete well customer service process to ensure the least time possible in an unsatisfied state.

Instead of focusing on surveillance, analysis or repair tasks, the team needs to deliver excellent customer service to each dissatisfied well.

Committed to reducing downtime

It’s possible to generate more cash and maximize asset value by incorporating human workfl ow data into the analytics used for continuous improvement by:

- Committing to minimizing the time wells are dissatisfied by defining and adhering to a “well customer service” process;

- Adopting standard operating procedures for the well customer service process. This replaces unique or random response actions and generates consistent data to assess the effectiveness of each process step while enabling continuous improvement;

- Developing tangible metrics such as time to reinforce the importance of efficient execution of the well process activities; and

- Creating visibility and accountability into the process by tracking wells through every handoff during execution of the “fix.”

Companies using digital technology to enhance both mechanical and human capabilities can outperform their competitors by increasing production through the reduction in well downtime. Tools like RPM can standardize human actions in the well intervention process, modernize measurement of value-adding tasks and reinforce utilization of the most effective, efficient remediation steps.

Marrying state-of-the-art process measurement with the well intervention process will create visibility, clarity and alignment for teams of operating and engineering personnel to get wells back to producing in the shortest time possible. These clear objectives and visibility will promote commitment and unleash the ingenuity of teams.

In the digital age machines are taking on routine tasks, but decisions, execution and process innovation will continue to benefit from a human touch.

Have a story idea for Tech Watch? This feature highlights leading-edge technology that has the potential to eventually address real-life upstream challenges. Submit your story ideas to Group Managing Editor Jo Ann Davy at jdavy@hartenergy.com.

Recommended Reading

Some Payne, But Mostly Gain for H&P in Q4 2023

2024-01-31 - Helmerich & Payne’s revenue grew internationally and in North America but declined in the Gulf of Mexico compared to the previous quarter.

Petrie Partners: A Small Wonder

2024-02-01 - Petrie Partners may not be the biggest or flashiest investment bank on the block, but after over two decades, its executives have been around the block more than most.

Murphy Oil Names Eric Hambly as President, COO

2024-02-08 - Murphy Oil has promoted Eric M. Hambly to president and COO and E. Ted Botner to executive vice president. Both will continue to report to CEO Roger W. Jenkins.

EOG Resources Wildcatting Veteran Billy Helms to Retire

2024-04-02 - Joining an EOG Resources predecessor in 1981, Helms is among the pre-1986-oil-bust generation who later found success in shale.

Thanks to New Technologies Group, CNX Records 16th Consecutive Quarter of FCF

2024-01-26 - Despite exiting Adams Fork Project, CNX Resources expects 2024 to yield even greater cash flow.