Rendering of direct air capture and sequestration facility being built in the Permian Basin through a partnership between Oxy Low Carbon Ventures and Canadian clean energy company Carbon Engineering. (Source: Carbon Engineering Ltd. )

[Editor's note: This article originally appeared in the February 2020 issue of E&P magazine. Subscribe to the magazine here.]

Energy companies around the world have adopted practices and technologies that have helped reduce their carbon footprint. And although those efforts are helping reduce greenhouse-gas (GHG) emissions on an incremental scale, the rapid adoption of cost-effective and large-scale carbon reduction technologies are likely what is needed to meet the goals of the Paris Agreement.

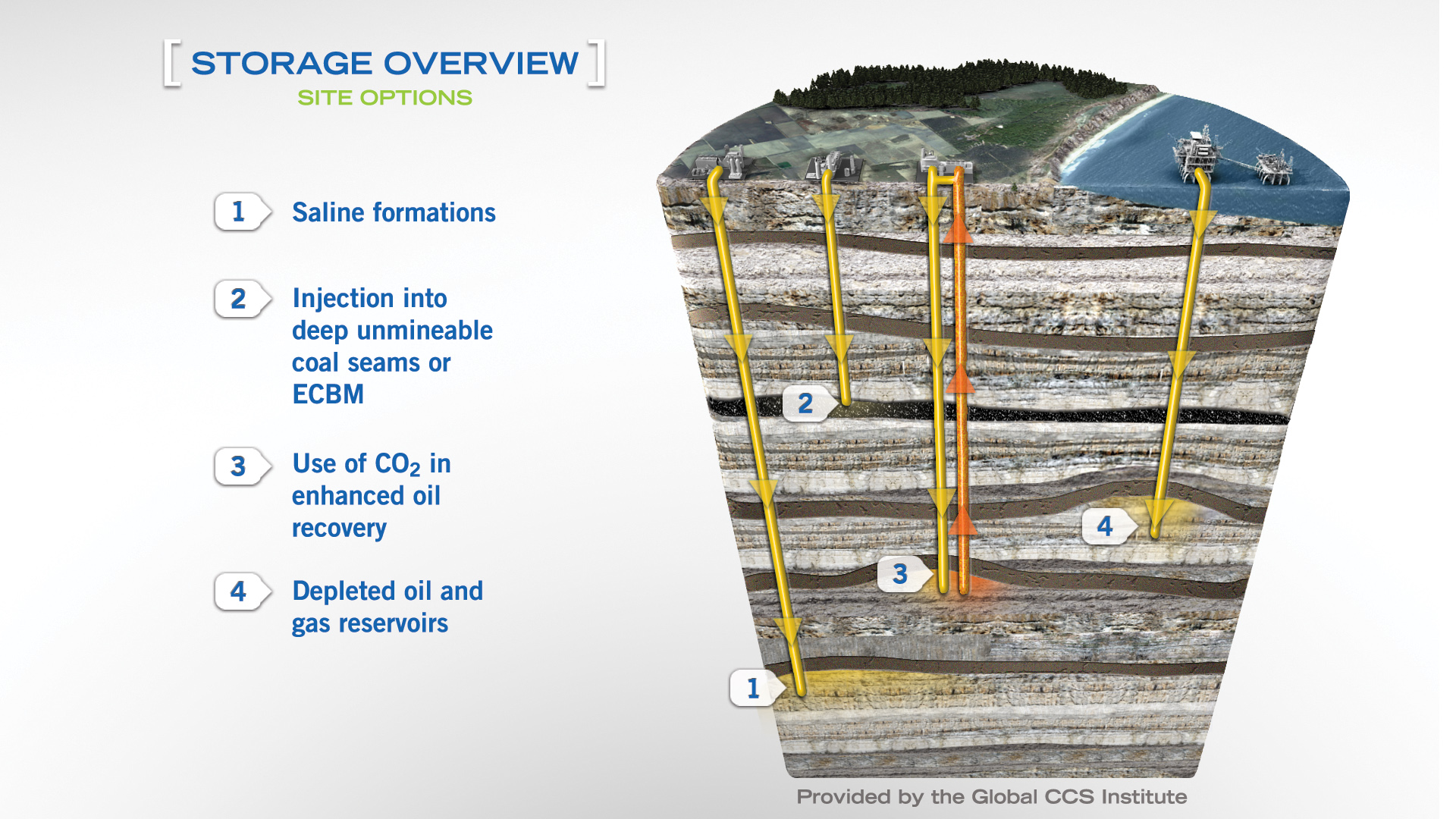

One of the technologies considered able to meet the cost and scale needs of global, widespread adoption is carbon capture, utilization and storage (CCUS). CCUS technologies capture CO2 from industrial processes and transport the CO2 via ship or pipeline, after which it is either stored deep underground or used as a resource to create products.

Under the International Energy Agency’s (IEA) Clean Technology Scenario, which sets out a plan consistent with the Paris Agreement’s climate initiative, CCUS would account for 7% of the cumulative emissions reductions needed globally by 2040.

“This implies a rapid scale-up of CCUS deployment, from about 30 million tonnes of CO2 currently captured each year to 2,300 [million tonnes] per year by 2040,” the IEA reported.

The UK Oil and Gas Industry Association’s “Energy Transition Outlook 2019” said developing CCUS technologies is a “fundamental requirement” for meeting its net-zero obligations.

However, according to McKinsey & Co., one significant challenge to widespread carbon reuse adoption is that carbon is a highly inert molecule, meaning transforming the captured gas into industrial products requires a lot of energy. Another challenge McKinsey cited is the quantity of CO2 that could be used for the creation of chemicals, plastics and carbon fiber would be too small to make an appreciable difference in global GHG emissions.

“Methods of carbon capture and use that take up much larger amounts of carbon dioxide gas will, therefore, be needed to help reduce overall GHG emissions,” McKinsey reported in a January 2018 article.

RELATED:

Carbon Capture Advocates Still Waiting For Way Forward

Work on such methods is well underway, if not fully in operation. According to the Global CCS Institute, 51 large-scale carbon capture and storage facilities around the world are in various stages of either operation or development, with most (23) in North America alone.

More efforts are on the way, from global initiatives by oil and gas supermajors to tax credits for carbon capture in the U.S. and continuing grant funding by the U.S. Department of Energy for industrial CCUS pilots. CCUS has become a priority for the Oil and Gas Climate Institute (OGCI), which counts among its members BP, CNPC, Eni, Equinor, Exxon Mobil, Chevron, Occidental, Pemex, Petrobras, Repsol, Saudi Aramco, Shell and Total.

OGCI KickStarter

In September 2019, the OGCI announced its KickStarter campaign, which is designed to boost largescale commercial CCUS worldwide. As part of the program, the OGCI will work to develop five emerging global hubs into operation in the U.K., the U.S., Norway, the Netherlands and China.

“The aim of KickStarter is to create the necessary conditions to really facilitate a commercially viable CCUS industry,” Sue-Ern Tan, group carbon relations manager at Shell, told E&P. “Because if you don’t have the right conditions, you’re not going to get companies making the investments and joining together, creating hubs for shared storage and transportation infrastructure.”

According to the OGCI, the KickStarter program has an early aspiration to double the amount of CO2 that is currently stored globally before 2030. The planned hubs and potential CO2 impact by 2030 have been identified at Teesside, U.K., with 6 million tonnes per year (mtpy) of CO2; Norway with 5 mtpy of CO2; Rotterdam, The Netherlands, with 10 mtpy of CO2; Xinjiang, China, with 3 mtpy of CO2; and the Gulf of Mexico with 200 mtpy of CO2. Of the five, the Teesside hub is the nearest to operation.

BP, Eni, Equinor, Occidental, Shell and Total have worked with the U.K., government in moving the project forward, which has required investments of $3 billion, according to the OGCI. BP has emerged as the principal operator of the Teesside hub, which is expected to enter the FEED phase this year.

The financing will come in part from the OGCI’s $1 billion-plus fund, which has 15 clean technology investments in its portfolio, according to the institute.

Tan said the biggest hurdle to develop not just the hubs cited in the KickStarter program but large-scale CCUS programs worldwide has been insufficient policies and regulations. She said the recent hike of the 45Q tax credit in the U.S. is an example of the policies needed globally to push CCUS to scale.

“That tax credit will make a big difference to the business models for those types of projects in the U.S.,” she said. “But we’re not getting that level of policy and regulation at the scale everywhere in the world that we need certainly to meet what is expected under the scenarios for the Paris Agreement. I think the consistency and deployment of those policies and regulations need to be far more widespread.”

Operator efforts

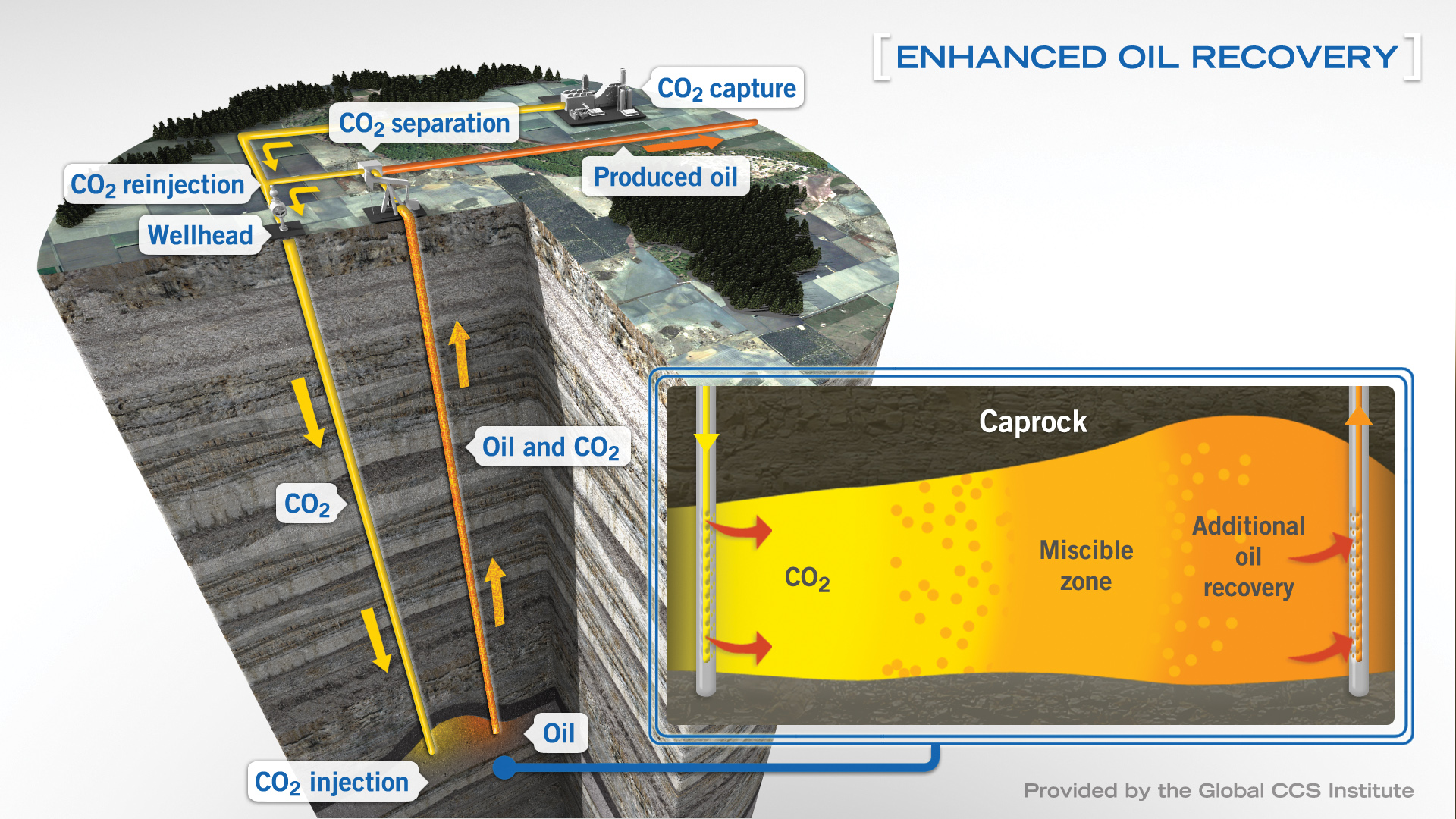

The leading operator in carbon capture efforts so far has been Occidental, which applies CO2 capture technologies for EOR floods in the Permian Basin of West Texas and Southeast New Mexico. According to the company, Occidental injects 2.6 Bcf/d of CO2 in the Permian, which translates to 950 Bcf/year. The company states that CO2 EOR can increase oil and associated gas recovery by 10% to 25%.

Meanwhile, Oxy Low Carbon Ventures (OLCV), a subsidiary of Occidental, announced two projects last year designed to lower carbon emissions. In May OLCV and Canadian clean energy company Carbon Engineering announced a plan to engineer and design the world’s largest direct air capture and sequestration facility. According to a press release, the companies are evaluating a facility to be located in the Permian Basin designed to capture 500 kilotonnes of CO2 from the atmosphere each year, which would then be used in Occidental’s EOR operations and eventually stored underground.

The release stated that pairing direct air capture with CO2 sequestration in EOR operations “is a significant step forward for the energy industry, as it provides a mechanism designed to greatly reduce or eliminate the net addition of CO2 to the atmosphere from oil production and use.”

In August OLCV reached an investment agreement with Cemvita Factory for the development of new bioengineered pathways that use CO2 as feedstock for sustainable production of intermediate chemicals and polymers. According to a press release, Cemvita Factory’s technology includes a CO2 utilization platform that mimics photosynthesis and other natural processes to produce industrial chemicals and polymers for energy sustainability.

Tara Karimi, Cemvita Factory’s co-founder and chief scientist, said the company has an “ambitious” goal of taking 1 gigaton of CO2 out of the carbon cycle over the next decade.

OLCV President Richard Jackson said in the release that “Cemvita Factory’s CO2 utilization platform has the potential to harness the power of nature and create new, sustainable pathways for the biomanufacturing of our products.”

Recommended Reading

MethaneSAT: EDF’s Eye in the Sky Targets E&P Emissions

2024-03-07 - The Environmental Defense Fund and Harvard University recently launched MethaneSAT, a satellite tracking methane emissions. The project’s primary target: oil and gas operators.

Exclusive: Scepter CEO: Methane Emissions Detection Saves on Cost

2024-04-08 - Methane emissions detection saves on cost and "can pay for itself," Scepter CEO Phillip Father says in this Hart Energy exclusive interview.

CAPP Forecasts $40.6B in Canadian Upstream Capex in 2024

2024-02-27 - The number is slightly over the estimated 2023 capex spend; CAPP cites uncertain emissions policy as a factor in investment decisions.

Air Liquide to Add CO2 Recycling at Plant in Germany

2024-02-08 - In a supply agreement, Air Liquide and Dow plan to add a new CO2 recycling solution to two air separation units and one partial oxidation plant.

1 Fatality in Equinor Helicopter Training Accident Offshore Norway

2024-02-29 - Equinor employee died following the helicopter accident, the cause of which has not been reported.