One study indicated using an e-frac system can save an operator over $1 million a month on fuel costs, Steve Goldstein, the unconventional growth and strategy leader for Baker Hughes industrial energy and technology, told attendees of Hart Energy’s Executive Oil Conference & Exhibition on Nov. 16. (Source: Baker Hughes Co.)

MIDLAND, Texas—Turbine-driven electric fracs are reducing emissions and delivering massive fuel savings to operators, and changing capital cost models put e-frac systems more within reach.

E-frac technology has continued to improve, and mobilization and demobilization times are much faster than in years past, according to Steve Goldstein, the unconventional growth and strategy leader for Baker Hughes industrial energy and technology.

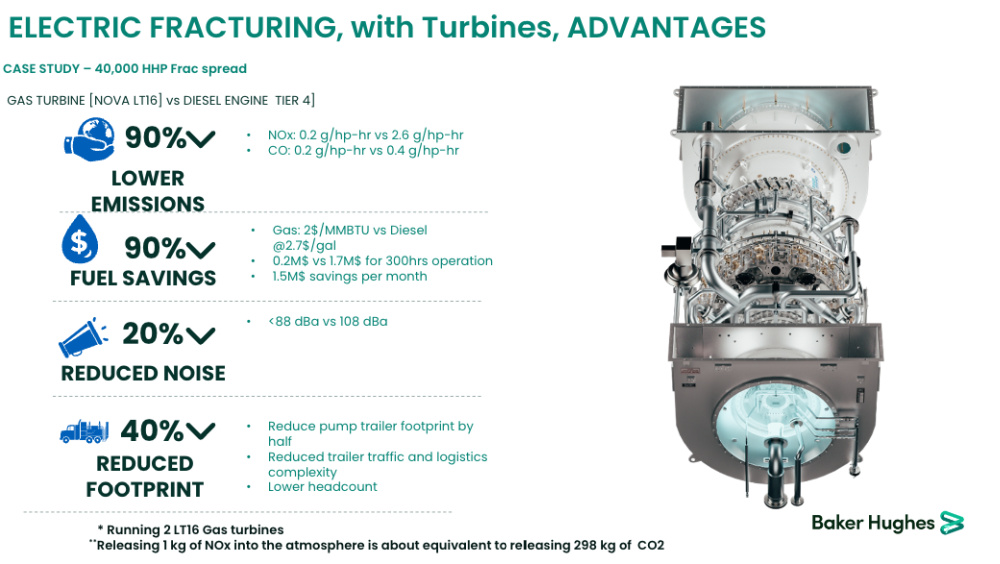

Speaking during Hart Energy’s Executive Oil Conference & Exhibition on Nov. 16, Goldstein told attendees turbine-driven e-fracs are reducing both fuel use and emissions by as much as 90% over traditional diesel-powered frac fleets, decreasing noise levels by 20% and dropping the footprint by 40%. And with vendors increasingly willing to lease e-frac systems, the economics of switching from traditional systems to turbine-driven systems mean operators won’t have to outlay a lot of capex to acquire access to the equipment.

In short, e-fracs use mobile gas turbines or engines instead of conventional diesel engines to generate the power that runs the process equipment used for hydraulic fracturing. Goldstein focused his comments around using a turbine distributed to an electric motor to drive the power.

Better ‘workhorses’

Historically, mobile turbines were “bulky. They were slow to be deployed. You got all these other economic savings, but you lost a lot of time in the field because it would take you days to set up,” Goldstein said.

Now, e-frac companies “are mobilizing and demobilizing in less than 24 hours,” he said.

“You can go out and see videos on the internet of e-frac power units being mobilized very quickly without cranes, without forklifts, without a lot of manpower and low maintenance intervals,” he added.

Compared to reciprocating engines, turbines can run about 35,000 hours before needing the first major maintenance. Reciprocating engines “are really good workhorses, but every couple hundred hours you're going to have to take them offline, overhaul them, replace parts.”

By contrast, he cited one turbine that had recently been taken offline for the first time after eight years of frack activity.

“All they did to this turbine throughout the years was change the filters on the package, make sure the fluids were okay,” he said. “Occasionally they do what’s called a borescope, where you look inside the turbine to make sure there’s no damage happening.”

“On top of that,” he continued, “you can actually do condition monitoring through remote diagnostics where someone sitting in a control room thousands of miles away can actually use, watch the performance of that turbine, compare it to other turbines in the fleet or in the database, and really understand how that turbine’s performing.”

Lab results using the same frac profiles as field jobs indicated a significant decrease in emissions when using turbines for e-frac, according to Goldstein.

“Things like methane leak aren’t going to happen. There’s no pistons in the turbine, so there’s no place for that methane slip to happen,” he said.

And the turbine-powered e-fracs are quieter than traditional systems.

“These machines are much quieter. They're much better at being a neighbor,” Goldstein said.

Looking toward the future, he said turbine technology is 100% hydrogen capable. While no companies are currently fracking with hydrogen, the ability to do so will be there, he added.

Money saver

One study indicated using an e-frac system can save over $1 million a month on fuel costs because it allows the use of field gas rather than diesel, Goldstein said. That study was done when diesel was priced at an average of $2.75/gallon.

“What are we playing now? 6, 5, 6 bucks a gallon for diesel?” he asked, adding the monthly fuel savings help justify an investment in turbine-driven e-frac systems. “Using a turbine, you’re going to have a hundred percent diesel displacement.”

Additionally, he said, when looking at the total cost of ownership from original capital purchase through operating costs, turbine-driven frac through power generation has the lowest total cost of ownership.

In the past, there was a challenge because upfront costs were higher because a company wanting to use turbine power technology would typically need to replace all of its additional equipment, he said.

Goldstein said that’s no longer much of an issue as companies are willing to lease the power equipment as well as the e-frac pumping equipment.

“You’re taking something that was initially thought of as a very intense capital purchase and converting it into something that is more of an operating cost where you can easily match your cost with your revenues,” he said.

Recommended Reading

US Drillers Add Oil, Gas Rigs for First Time in Five Weeks

2024-04-19 - The oil and gas rig count, an early indicator of future output, rose by two to 619 in the week to April 19.

Strike Energy Updates 3D Seismic Acquisition in Perth Basin

2024-04-19 - Strike Energy completed its 3D seismic acquisition of Ocean Hill on schedule and under budget, the company said.

Santos’ Pikka Phase 1 in Alaska to Deliver First Oil by 2026

2024-04-18 - Australia's Santos expects first oil to flow from the 80,000 bbl/d Pikka Phase 1 project in Alaska by 2026, diversifying Santos' portfolio and reducing geographic concentration risk.

Iraq to Seek Bids for Oil, Gas Contracts April 27

2024-04-18 - Iraq will auction 30 new oil and gas projects in two licensing rounds distributed across the country.

Vår Energi Hits Oil with Ringhorne North

2024-04-17 - Vår Energi’s North Sea discovery de-risks drilling prospects in the area and could be tied back to Balder area infrastructure.