While drilling for oil and gas is not a new concept, new reservoirs located deeper in the earth and in deeper waters are placing unprecedented challenges on drillers to safely and cost-effectively deliver a well to its target depth. Meeting these challenges requires more than better tools. A step-change in the drilling process is needed.

Closed-loop drilling (CLD) systems offer such a change. Replacing a rig’s conventional circulating system – which is open to the atmosphere – with pressurized, closed-loop technology provides flexibility when needed. A CLD-ready rig provides the framework to rapidly integrate a range of CLD technologies as the well dictates, such as riser gas handling, advanced flow detection, and various methods of managed-pressure drilling (MPD).

MPD has proven to be a key technology for challenging wells, particularly in deep water, where it helps the driller navigate the challenges of depleted reservoirs, narrow drilling windows, and HP/HT well bores that routinely threaten the structural stability and economics of a well.

Yet despite the benefits, the industry’s adoption of MPD in deep water has been slow.

Although the value and understanding of MPD has been accelerating at an exponential rate, the cost and time associated with outfitting an MPD package onto a floating rig has become an implementation barrier.

The ultimate solution to overcome these barriers is to collaborate with drilling contractors to design or retrofit a rig that has the correct configuration, dimensions, and ancillary equipment to accept MPD components quickly and efficiently.

Getting a rig ready for MPD can only come through a coordinated industry effort that focuses on the development of procedures and standards for equipment procurement, rig modification and design, and training for all stakeholders in the drilling process.

Setting standards

To avoid the need to customize each rig for every MPD application, several components of the MPD deployment process must be streamlined and standardized. This begins by developing a procurement process that reduces costs and the time to acquire and move equipment to location.

To further shorten lead times, MPD components and configurations must be clearly specified for various MPD applications, and drilling contractors should be willing and ready to deliver ancillary equipment that is compatible with MPD-specific equipment supplied by the service provider.

Many times this is a case of ensuring that equipment of the right size is available. For example, drilling contractors typically have upper ball joints, tension rings, and telescopic joints on the rig, but the IDs may not be adequate for the ID of the bearing assembly for a rotating control device (RCD) – an enabling technology for these techniques. The service provider must deploy ancillary equipment of the right size, adding time and significant cost to the operation.

Standardization of the rig floor also is a requirement for efficient MPD operations. An MPD package will require special accommodation, which is problematic for existing semisubmersibles and drillships. For existing rigs there is a general lack of standardization across existing deepwater rig designs, making it difficult to deploy an MPD system ad-hoc.

Increased collaboration among all interested parties – the drilling contractor, service company, and operator – would minimize costs and lead times, ultimately accelerating the adoption of MPD.

For this to happen, templates for rig modifications must be developed to provide a clear process for implementing an MPD refit. Specifications should be developed for MPD “kits” that describe basics such as deck loads, footprints, and riser specifications as well as flowlines, air, electrical, and hydraulic connections.

Paperwork and people

Interface documentation between the MPD process and rig is another necessary objective. Generic procedural templates could address up to 80% of the MPD process with the rest customized according to job, rig, and well factors. Efforts by industry organizations such as the IADC are a welcome step to developing MPD best practices that could be implemented in this documentation.

Development of industry training standards for MPD is critical. Safety and performance depends on fostering an understanding of MPD operations that equals conventional drilling operations. The standardization of MPD training will ensure that competencies gained thus far on land and fixed platforms are easily transferable to floating rigs.

Benefits of MPD readiness

Standards and expertise on the rig floor that ensure the development of MPD rig designs will provide several tangible benefits for both drilling contractors and operators.

Reduced planning cycle. Building MPD capabilities into the rig can significantly shorten the lead-time on equipment and get the drilling operation started sooner. Currently, when an operator wishes to perform MPD on a floater, rig-specific customization is required, which can take up to 12 months. By having MPD capability already integrated on the rig, the planning cycle is shortened to only three to four months.

In addition, for wells that are drilled conventionally but encounter a trouble zone in the reservoir requiring MPD, a rig that is ready to perform MPD can quickly make the transition and continue drilling the well with minimal nonproductive time.

Increased operational safety. The presence of the right MPD equipment on the rig enhances process safety and allows the operator to make better drilling decisions. For example, by having an enabling technology such as Weatherford’s SeaShield RCD permanently installed in the riser as part of the Microflux degasser system, the driller can quickly convert from a conventional drilling scenario where the riser has to be degassed to MPD mode to safely drill the remainder of the section.

Ultimately, with access to a rig that is already capable of performing MPD, the operator does not have to settle for drilling through a complex reservoir using conventional techniques.

Improved operational costs. If a drilling contractor does not have equipment of the correct size or scope to run MPD, it falls on the service provider to purchase and deploy it. This large cost for equipment, which the service provider would not typically hold in its inventory, will be charged to the operator as part of the day rate.

A significant operational cost reduction is realized if the contractor holds this equipment, with the right IDs, has the space on the rig floor, and has the capability to deploy it subsea. By transferring the cost of capital from the service provider to the drilling contractor, the operator will see a reduction in the cost of MPD with asset depreciation changing from about 10 to 30 years, respectively.

As MPD becomes more commonly applied, ownership of critical riser items will transition to the drilling contractor, including the flow spool, drillstring isolation tool, and RCD housing. This will enable MPD deployment as a standard package – a plug-and-play solution that will make owners of such rigs highly sought after.

Recommended Reading

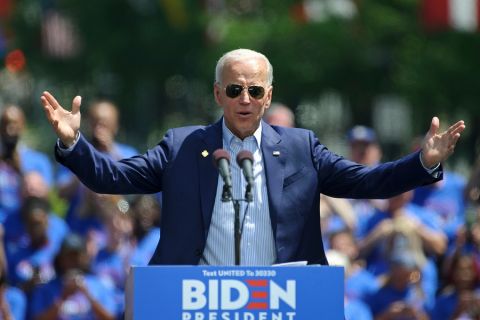

Biden Totters the US LNG Line Between Environment, Energy Security

2024-01-30 - Recent moves by U.S. President Joe Biden targeting the country’s LNG industry, which has a number of projects in the works, are an attempt to satisfy environmentalists ahead of the next upcoming presidential election.

EQT’s Toby Rice: US NatGas is a Global ‘Decarbonizing Force’

2024-03-21 - The shale revolution has unlocked an amazing resource but it is far from reaching full potential as a lot more opportunities exist, EQT Corp. President and CEO Toby Rice said in a plenary session during CERAWeek by S&P Global.

The Problem with the Pause: US LNG Trade Gets Political

2024-02-13 - Industry leaders worry that the DOE’s suspension of approvals for LNG projects will persuade global customers to seek other suppliers, wreaking havoc on energy security.

Pitts: Producers Ponder Ramifications of Biden’s LNG Strategy

2024-03-13 - While existing offtake agreements have been spared by the Biden administration's LNG permitting pause, the ramifications fall on supplying the Asian market post-2030, many analysts argue.

Belcher: Election Year LNG ‘Pause’ Will Have Huge Negative Impacts

2024-03-01 - The Biden administration’s decision to pause permitting of LNG projects has damaged the U.S.’ reputation in ways impossible to calculate.