The PDC cutting elements possess metallic fracture toughness that is more than 100% higher than that of current PDC cutters. (Source: Saudi Aramco)

[Editor's note: A version of this story appears in the June 2020 edition of E&P. Subscribe to the magazine here. It was originally published June 1, 2020.]

Polycrystalline diamond compact (PDC) drill bits have been historically used as key drilling tools and have dramatically changed the oil and gas industry since their introduction in the 1970s. Currently, PDC bits account for about 90% of the total drill bit market due to significant advancements in PDC cutter technology, including deep leaching process applications. However, drilling hard, highly abrasive and interbedded formations is a challenge for PDC bits that are currently being used in the industry, which do not provide sufficient wear or impact resistance nor adequate thermal stability to drill entire intervals in a single run. This is due to the use of unavoidable cobalt catalyst needed to bind the diamonds that compose the PDC cutting structure.

Eliminating the use of catalysts, Saudi Aramco has released the Ultra-HP/HT technology to manufacture catalyst-free ultra-strong PDC cutting elements, explained David Zhan, the R&D team leader of the Drilling Technology Division at the EXPEC Advanced Research Center at Saudi Aramco’s headquarters in Dhahran.

The company has developed the technology in collaboration with Chengdu Dongwei Technology Co., the world’s only ultra-HP/HT technology provider.

Overcoming challenges

Removal of cobalt, a key ingredient in the manufacturing process, is the challenge in optimizing the performance of PDC cutters made for traditional HP/HT use.

“The PDC cutter relies on a distributed network in which the crystals are strongly combined. The key point is to bond them together with metal catalysts, usually cobalt. It is also used to combine the diamond cutting element tables with substrates like tungsten carbide,” Zhan said.

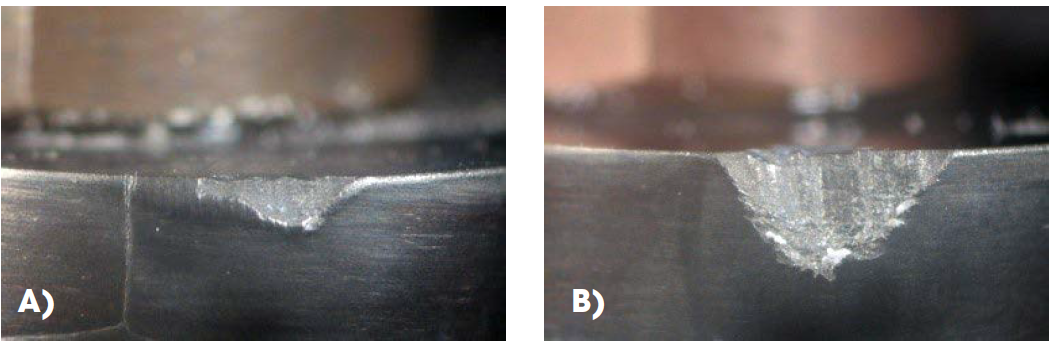

He pointed out that the problem arises when the cobalt residue heats up due to intense friction during the drilling process, which causes the metal to expand more than the diamond until it begins to split. The expansion of cobalt also leads to the development of cracks, resulting in failure.

Zhan has previously worked on the development of a film with a scanning electron microscope (SEM) to demonstrate the consequences of heating a PDC sample under controlled reservoir conditions.

“Due to the heat, irregular cracks appear [and] the material dims, turning the once evenly surface into something similar to the cracked mud seen at the bottom of a dry pond,” Zhan said, adding that he has contributed in-depth research to deep leaching technology—one of the possible solutions to the problem. This solution involves dipping the PDC into acid to leach most of the cobalt.

“The industry is researching improved leaching methods or other methods to further reduce the effects of cobalt. But it also has its limitations as some metals are sealed in spaces that the liquid cannot reach and are left behind,” Zhan said.

Discussing the findings of a PDC cutter’s typical microstructure under SEM, he said, a PDC cutter is made up of a continuous network of diamond coexisting with a cobalt catalyst binder distributed in interstices.

“The cobalt catalyst could have both beneficial and detrimental effects on the cutter performance,” he said. “During PDC cutter manufacturing, the cobalt catalyst enhances strong diamond-to-diamond bonding and lowers the sintering temperatures and pressures as well.

“However, cobalt can also expand to break diamond-to-diamond bonding during drilling, especially for hard and abrasive formations, resulting from frictional heat generated from cutter/rock interface. That’s why the PDC industry is working on leaching and other emerging technologies to reduce cobalt in the cutter with a rapid pace of improvements,” Zhan said.

Research

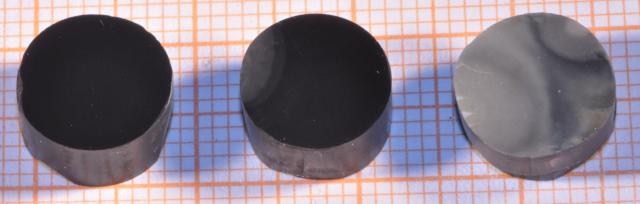

Saudi Aramco has documented the successful synthesis of catalyst-free PDC compacts in centimeter size under ultrahigh pressure of 16 GPa and ultrahigh temperature of 2,300 C using micron diamond powder as the starting material. A large sample dimension of more than 10 mm in diameter and up to 6 mm in thickness has been achieved, which are sufficiently large enough and cost-effective to make parts and components for not only hydrocarbon drilling but also a wide range of other industrial applications.

“Across the industry, the goal is for PDC cutters to be able to endure long periods of time at high temperatures as they cut through hard, variable formations,” Zhan explained, adding that the industry’s rule of thumb is that temperatures higher than 750 C damages the PDC cutter and leaching pushes that limit to about 1,200 C.

“Although there have been many attempts to further optimize these limits, Saudi Aramco has successfully developed the Ultra-HP/HT technology to manufacture catalyst-free ultra-strong PDC cutting elements,” Zhan said.

Features

The new method manufactures diamond-cutting materials with ultrahigh wear resistance, which is 300% higher than the PDC cutters currently used in the industry, according to the developers. The development of an ultra-strong and catalyst-free PDC cutter delivers significant increases in performance, durability and improved well economics, according to the company.

Conventional HP/HT technology has a synthesis capability of pressures ranging from 5.5 GPa to 7 GPa. Saudi Aramco’s Ultra-HP/HT technology used a two-stage multi-anvil apparatus with high-pressure assembly designs for generating ultrahigh pressures up to 35 GPa—seven times higher than current PDC cutters—as well as ultrahigh temperatures of up to 2,300 C.

Saudi Aramco said the PDC cutting elements possess metallic fracture toughness that is more than 100% higher than that of current PDC cutters. The material is catalyst-free and has the highest thermal stability of up to 1,200 C in air, which is 600 C higher than the best commercial PDC materials, according to the company.

Moving forward

During Phase 1 of the research, laboratory testing of the catalyst-free PDC cutting materials synthesized by the Ultra-HP/HT technology proved its potential in E&P and drilling operations as well as in physics, aerospace science, geoscience and petroleum engineering.

Zhan concluded, “Our next step in Phase 2, which we are currently working on, is to join or bond the ultra-strong catalyst-free PDC cutting elements or layers onto a substrate to form a full-scale PDC cutter that will be attached to the drill bit body for field testing. Once the field testing is completed, the technology will be deployed in our operations.”

Recommended Reading

SilverBow Rejects Kimmeridge’s Latest Offer, ‘Sets the Record Straight’

2024-03-28 - In a letter to SilverBow shareholders, the E&P said Kimmeridge’s offer “substantially undervalues SilverBow” and that Kimmeridge’s own South Texas gas asset values are “overstated.”

Flame Acquisition Holders Approve Merger with Sable Offshore

2024-02-14 - The business combination among Flame Acquisition Corp., Sable Offshore Holdings and Sable Offshore Corp. will be renamed Sable Offshore Corp.

Greenbacker Names New CFO, Adds Heads of Infrastructure, Capital Markets

2024-02-02 - Christopher Smith will serve as Greenbacker’s new CFO, and the power and renewable energy asset manager also added positions to head its infrastructure and capital markets efforts.

TPG Adds Lebovitz as Head of Infrastructure for Climate Investing Platform

2024-02-07 - TPG Rise Climate was launched in 2021 to make investments across asset classes in climate solutions globally.

Stockholder Groups to Sell 48.5MM of Permian Resources’ Stock

2024-03-06 - A number of private equity firms will sell about 48.5 million shares of Permian Resources Corp.’s Class A common stock valued at about $764 million.